What Are the 4 Main Types of Casting Processes?

In our decades of metal manufacturing experience, we’ve mastered all four fundamental casting methods – each solving different production challenges with unique approaches to metal forming.

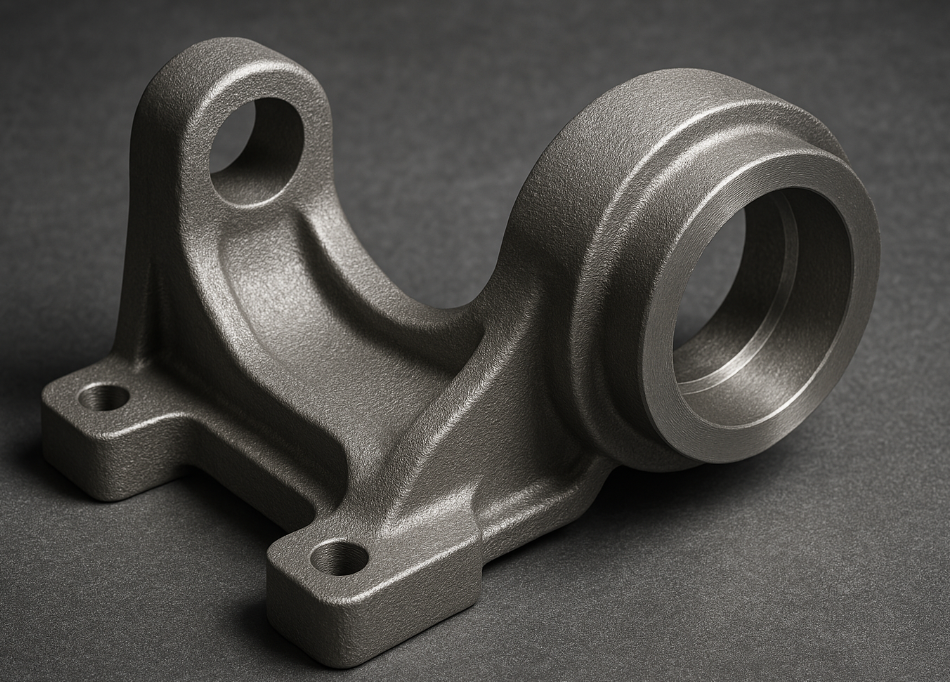

Snippet paragraph: The four primary casting methods are sand casting (versatile for large parts), die casting (high-speed precision), investment casting (complex geometries), and centrifugal casting (hollow cylinders) – each offering distinct advantages in production volume, precision, and cost structure.

Choosing the right casting method significantly impacts your project’s success.

LOOP_START

How Does Sand Casting Work and When Should You Use It?

Sand casting remains the most flexible casting method after thousands of years of development.

Snippet paragraph: Sand casting creates parts by pouring molten metal into sand molds – offering low tooling costs for prototypes and large components while accommodating virtually any metal alloy, though with relatively rough surface finishes (12.5-25µm Ra typical).

Sand Casting Technical Specifications

| Parameter | Range | Comparison to Other Methods |

|---|---|---|

| Dimensional Tolerance | ±1.5mm | 15x looser than die casting |

| Surface Finish | 12.5-25µm Ra | 5x rougher than investment |

| Minimum Wall Thickness | 3mm | 6x thicker than die casting |

| Mold Cost | $500-$5,000 | 10x cheaper than permanent molds |

Sand System Components

| Material | Purpose | Lifetime |

|---|---|---|

| Silica Sand | Mold base | Reused 5-10 times |

| Bentonite Clay | Binder | Replenished 5-10% per cycle |

| Coal Dust | Surface finish | Consumed |

| Water | Activation | Evaporates |

Optimal Applications

- Engine blocks (200kg+ gray iron castings)

- Marine propellers (corrosion-resistant bronze)

- Industrial equipment housings (low-volume steel)

LOOP_END

LOOP_START

What Makes Die Casting Different From Other Methods?

Die casting achieves unmatched production speeds through reusable steel dies.

Snippet paragraph: Using 10-175MPa pressure to inject metal into steel molds, die casting produces parts with ±0.025mm tolerances at 50-200 shots/hour – ideal for high-volume aluminum/zinc components like gear housings and electronic enclosures.

Die Casting Performance Metrics

| Characteristic | Cold Chamber | Hot Chamber |

|---|---|---|

| Pressure Range | 20-175MPa | 7-15MPa |

| Alloy Types | Aluminum, Copper | Zinc, Magnesium |

| Cycle Time | 30-90s | 10-30s |

| Energy Usage | 8-12kWh/kg | 4-6kWh/kg |

Cost Structure Comparison

| Factor | Die Casting | Sand Casting |

|---|---|---|

| Tooling Cost | $20,000-$200,000 | $500-$5,000 |

| Labor Cost/part | $0.25-$1.50 | $5-$20 |

| Material Yield | 95% | 85% |

| Economic Volume | 10,000+ | 1-5,000 |

Key Limitations

- Restricted to lower melting point metals

- High initial tooling investment

- Limited to smaller part sizes (<50kg typically)

LOOP_END

LOOP_START

When Should You Choose Investment Casting?

Investment casting delivers precision for complex geometries.

Snippet paragraph: Also called "lost-wax casting," this process creates ceramic molds from wax patterns, achieving ±0.3mm tolerances and 1.6-3.2µm surface finishes for aerospace turbine blades and medical implants where precision justifies higher costs.

Process Step Breakdown

| Stage | Time Required | Material Cost |

|---|---|---|

| Pattern Making | 4-20 hours | $25-$500 wax |

| Shell Building | 2-7 days | $50-$200 ceramic |

| Dewaxing | 1 hour | NA |

| Pouring | 15-60 minutes | Metal cost +20% |

Tolerance vs. Complexity

| Feature | Achievable Tolerance |

|---|---|

| Basic Dimensions | ±0.3% of dimension |

| Cored Holes | ±0.13mm diameter |

| Surface Finish | 1.6-3.2µm Ra |

| Thin Walls | 0.75mm minimum |

Industry Applications

- Aerospace: Single-crystal turbine blades

- Medical: Cobalt-chrome joint replacements

- Military: Complex firearm components

LOOP_END

LOOP_START

What Are the Unique Advantages of Centrifugal Casting?

Centrifugal forces create superior metallurgy for rotationally symmetric parts.

Snippet paragraph: By spinning molds at 300-3000 RPM during pouring, centrifugal casting produces dense, pure metal structures ideal for pipes, rings and sleeves – achieving 10-15% better mechanical properties than static casting methods for these shapes.

Centrifugal vs Static Casting Comparison

| Property | Centrifugal | Static | Improvement |

|---|---|---|---|

| Density | 99.5% | 97% | +2.5% |

| Tensile Strength | 550MPa | 485MPa | +13% |

| Inclusion Size | 5-20µm | 25-100µm | 5x smaller |

| Radial Quality | Uniform | Variable | Consistent |

Process Variations

| Type | Orientation | Best For |

|---|---|---|

| True Centrifugal | Horizontal | Pipes, tubes |

| Semi-Centrifugal | Vertical | Wheels, gears |

| Centrifuge | Multi-Axis | Small precision parts |

Material Performance

- Iron pipes: 50% longer service life

- Bronze bearings: 3x wear resistance

- Steel cylinders: Better pressure rating

LOOP_END

Conclusion

Understanding sand, die, investment and centrifugal casting methods enables optimal process selection for your specific part requirements and production volumes.