2025 Global Ranking of Custom Threaded Aluminum Parts Companies?

Introduction: Why Custom Threaded Aluminum Parts Matter

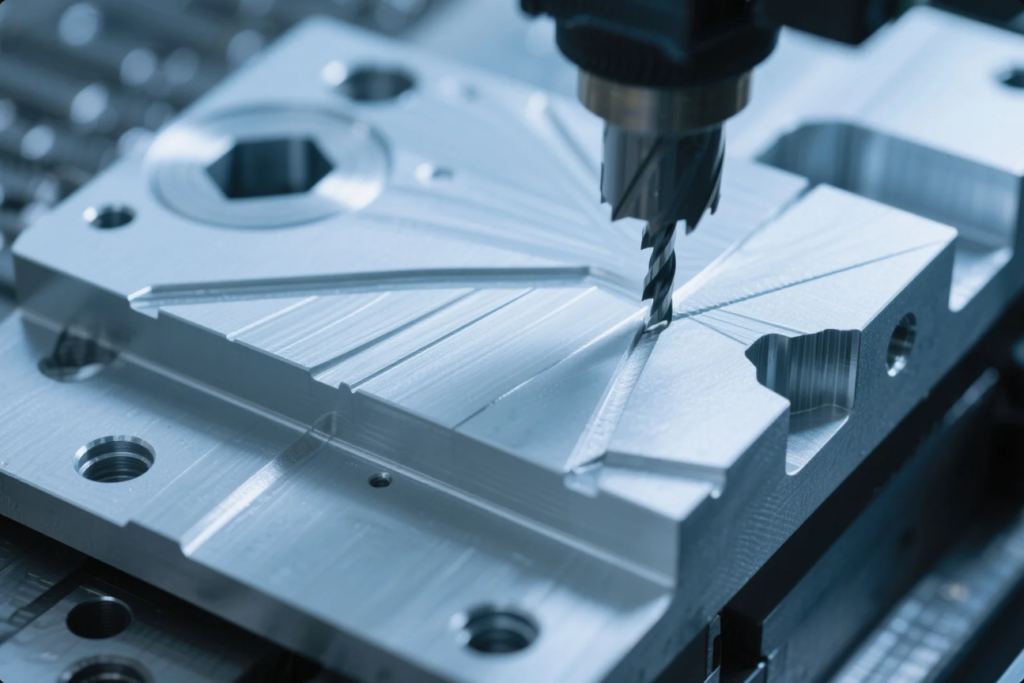

Custom threaded aluminum parts are used in aerospace, automotive, medical, and energy industries. These components require tight tolerance and high reliability.

However, common challenges buyers face include:

- Threading inconsistencies that cause assembly issues.

- Delayed deliveries disrupting production.

- Hidden costs due to rework or poor logistics.

This article will help you navigate these challenges, evaluate supplier capabilities, and discover why PrimeCustomParts.com is leading in precision threaded aluminum parts.

How to Identify a Reliable Custom Threading Manufacturer

Problem: Threaded parts often look identical but vary in precision.

Solution: Use standardized methods to evaluate vendor capability.

Snippet

Look for ISO 9001 certification, first-article inspection (FAI), and barcode-based traceability systems.

Key Evaluation Criteria

- ISO 9001 Certified: Ensures quality processes and accountability.

- CMM and pitch gauges: Verify dimensional precision.

- FAI Reports: Confirm specs are met on first run.

- Traceability: Connects every batch to specific machines, operators, and material lots.

| Requirement | Why It Matters | Where to Learn More |

|---|---|---|

| ISO Certification | Validates system quality control | iso.org |

| CMM Equipment | Ensures measurement accuracy | Wikipedia: Coordinate-measuring_machine |

| FAI Reporting | Prevents early-run defects | Wikipedia: First_article_inspection |

| Barcode Tracking | Ensures recall readiness and auditability | Wikipedia: Traceability |

Price vs. Precision: Which Threading Services Are Worth It

Problem: Some low-cost suppliers compromise on critical tolerances.

Solution: Calculate total lifecycle cost including rework and downtime.

Snippet

Tighter tolerances reduce failure rates. Use MIT Sloan logic—spend more upfront to save downstream.

Key Trade-offs

- Budget Tolerances: ±0.15 mm–0.20 mm

- [Mid-grade]: ±0.10–0.05 mm for industrial assemblies

- [High Precision]: ±0.01–0.03 mm for safety-critical components

| Grade | Tolerance (mm) | Use Case | Cost Implication |

|---|---|---|---|

| Budget | ±0.15–0.20 | Non-critical frames | Cheapest per piece |

| Mid-grade | ±0.10–0.05 | Machine assemblies | Balance of cost and quality |

| High-End | ±0.03 or better | Aerospace, medical equipment | Highest precision |

Pro Tip: The FAA and FDA both require high-precision documentation for threaded components used in regulated industries.

Top Regions for Aluminum Threaded Part Production

Problem: Sourcing from the wrong region increases cost or risk.

Solution: Match your priorities (speed, cost, quality) with region strengths.

Snippet

Compare cost, logistics, and quality across China, India, North America, and Europe.

| Region | Cost | Lead Time | Quality | Resource Link |

|---|---|---|---|---|

| China | Low–Mid | 2–3 weeks | Improving | export.gov/China |

| India | Low | 3–5 weeks | Varies | makeinindia.com |

| North America | High | 1–2 weeks | High | nist.gov (Standards & Materials) |

| Europe | Premium | 2–4 weeks | Top-Tier | ec.europa.eu (EU Industry Policies) |

PrimeCustomParts.com’s Competitive Edge in Aluminum Threaded Parts

Problem: Most suppliers lack traceability or quality control.

Solution: PrimeCustomParts.com delivers industry-best capabilities.

Snippet

Certified, high-speed production with real-time quality control and export-ready logistics.

Why Choose Prime

- ISO 9001 & TS 16949 certified

- ±0.01–0.03 mm thread tolerance

- CMM inspection for every batch

- Barcode traceability

- 10–15 day global shipping

- MOQ from 50 pcs

| Feature | PrimeCustomParts.com | Common Vendors |

|---|---|---|

| Certification | ISO + TS16949 | ISO or none |

| Inspection | CMM, optical, pitch gauges | Manual checks |

| Traceability | Digital barcoding | Basic labeling |

| Packaging | Foam trays, branding available | Bulk bags |

| Lead Time | 10–15 days | 20–30 days |

FAQs

What’s the MOQ?

Minimum order is 50 units.

Do you support global shipping?

Yes. Air, sea, and courier logistics supported.

What quality checks are in place?

FAI, CMM reports, barcode traceability, and monthly audits.

Can I get a sample?

Yes. Contact us with specs and we’ll arrange it.

Can you follow specific thread standards?

We support ISO, [UN], BSP, [JIS], and custom threads.

Conclusion & Contact Information

PrimeCustomParts.com offers world-class certification, advanced inspection systems, and reliable export capability. We help you minimize production delays and quality issues.

Contact our expert team for a free quote and consultation:

Email: [email protected]

Website: https://primecustomparts.com/