2025 Guide: Top Industrial Applications of Custom Metal Molds?

Global manufacturers seek durable, repeatable solutions. Poorly designed molds cause costly downtime.

Custom metal molds help industries produce precision parts at scale. They improve repeatability, strength, and design flexibility.

This 2025 guide explores key mold processes, their future outlook, casting types, and how to create your own metal parts.

What are the five metal casting processes?

Casting processes shape molten metal into final products using molds. Each process has unique advantages.

The five major metal casting processes are sand casting, die casting, investment casting, permanent mold casting, and centrifugal casting.

Casting Method Comparison

| Process | Key Benefit | Best For |

|---|---|---|

| Sand Casting | Low cost, large parts | Engine blocks, pump housings |

| Die Casting | Fast, high-volume, tight tolerances | Electronic housings, gears, brackets |

| Investment Casting | High detail, complex shapes | Valves, turbine blades |

| Permanent Mold Casting | Smooth surface, repeatable output | Automotive suspension parts |

| Centrifugal Casting | Ideal for symmetrical shapes | Pipes, sleeves, bushings |

We’ve delivered custom molds across all these processes. Our team helped an Italian client switch from sand casting to permanent mold casting—reducing cycle time by 40% for their marine gearbox components.

Read more at Engineering Choice – Types of Casting.

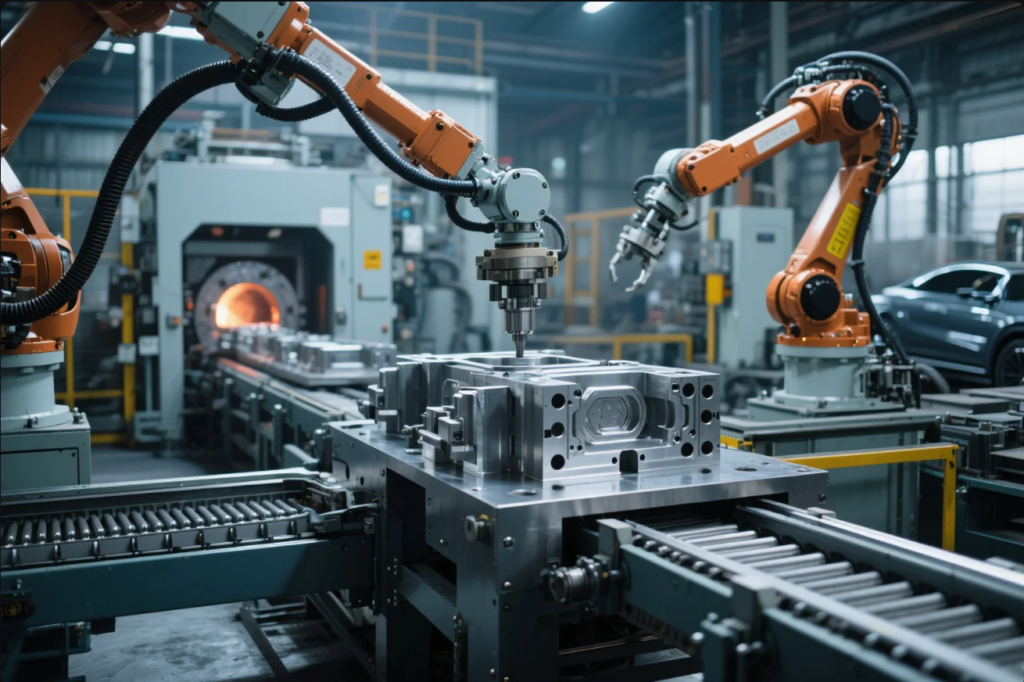

What is the outlook for the metal manufacturing industry?

Global industries demand stronger, lighter, and more complex metal parts.

In 2025, the metal manufacturing market is projected to exceed \$1.2 trillion, driven by automotive, EV, aerospace, and energy applications.

Industry Growth Trends (2025)

| Sector | Forecast Growth | Key Drivers |

|---|---|---|

| Automotive | 6.8% CAGR | Lightweight EV components, heat sinks |

| Aerospace | 9.2% CAGR | Complex alloys, 3D investment castings |

| Industrial Machinery | 7.5% CAGR | Custom molds, smart robotics |

| Energy | 8.1% CAGR | Wind turbine brackets, electrical connectors |

At Prime, we’ve noticed rising demand for CNC molds used in EV battery enclosures and ISO-certified die casting molds for drones and robotics. Our team collaborates with global buyers to optimize molds for automation and precision.

Industry-wide data source: Statista – Manufacturing Market Overview

What are the four types of metal casting?

Understanding core casting types helps engineers choose the right mold design.

The four primary casting types are sand casting, die casting, permanent mold casting, and investment casting.

Casting Type Comparison

| Type | Strengths | Limitations |

|---|---|---|

| Sand Casting | Flexible, low tooling cost | Rough surface, low precision |

| Die Casting | High volume, detailed parts | Limited to non-ferrous alloys |

| Permanent Mold | Reusable, excellent finish | Less suited for complex geometries |

| Investment Casting | Excellent accuracy, thin walls | Higher cost, longer cycle |

At Prime, we often recommend investment casting for parts under 5mm wall thickness and die casting for parts needing 50,000+ pieces/year. For structural aluminum parts, permanent molds with CNC finishing deliver exceptional results.

Explore technical details on Wikipedia – Metal Casting.

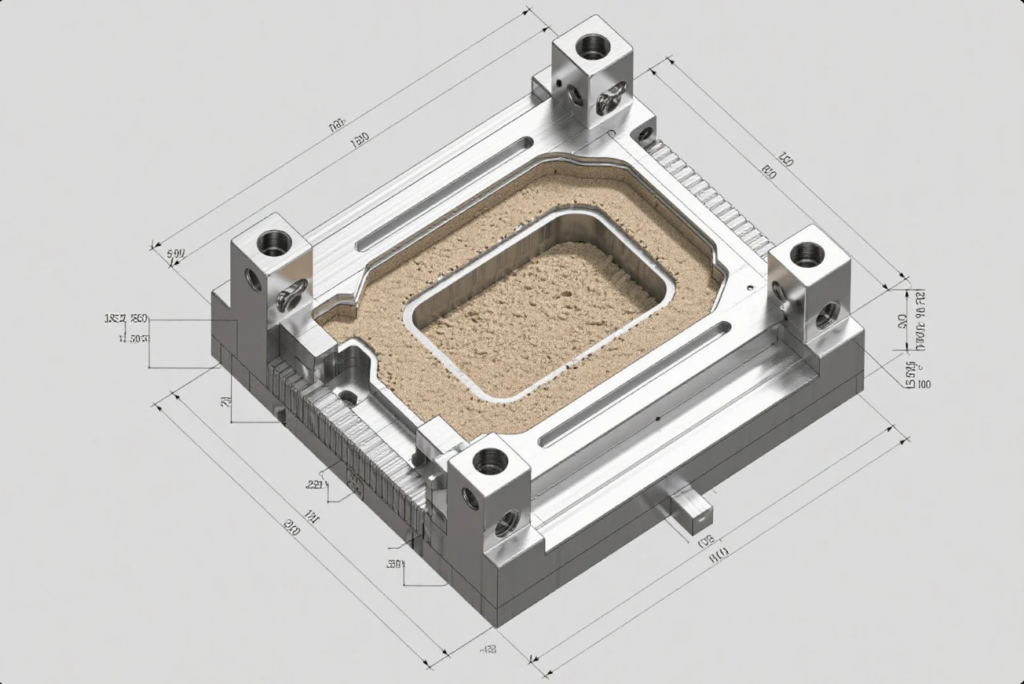

How to create metal parts?

Engineers often ask: “How do I turn my design into a real metal part?”

The metal part creation process includes CAD design, mold development, material selection, casting or machining, and final finishing.

Steps to Create Custom Metal Parts

- CAD Design – Create using SolidWorks or Fusion360

- Design for Manufacturability (DFM) – Prime helps adjust geometry for moldability

- Mold Production – CNC machining, EDM, or additive insert builds

- Trial and Sampling – 1st article inspection and testing

- Mass Production – With stamping, CNC, die casting, or investment casting

- Surface Treatment – Zinc plating, anodizing, or powder coating

- QC & Certification – Dimensional reports, hardness testing, CMM

We helped a U.S. robotics startup scale from 20 prototype gearboxes to 10,000 units/month using hybrid molds—combining CNC and permanent casting in a modular system.

FAQs

1. What casting is best for tight tolerances?

Investment casting and high-pressure die casting offer the best dimensional accuracy (±0.05 mm).

2. Can Prime handle export logistics and documentation?

Yes. We handle HS codes, CE docs, wooden crate packaging, and global shipping to 30+ countries.

3. Do you support custom logo engraving?

Yes. We use laser etching and EDM inserts to create logos, part numbers, and traceability codes.

4. Can you modify molds for design revisions?

Yes. Our in-house CNC allows fast insert swaps and core pin changes for rapid mold adjustments.

5. What certifications do your molds meet?

All molds meet ISO 9001 and comply with RoHS and CE marking standards.

Conclusion

Custom metal molds power innovation in every industry—from aerospace to electronics.

Choose Prime for precision molds, fast lead times, and trusted export service.

📞 Email: [email protected]

🌐 Website: https://primecustomparts.com

We turn your part ideas into production-ready reality—on time, every time.