What surfaces should not be directly welded on?

Which Surfaces Should Never Be Directly Welded? During our 30 years of metal fabrication, we’ve identified several high-risk surfaces that cause welding failures – from toxic fumes to structural cracks. These 7 surfaces require special treatment before welding: 1) Galvanized/zinc-coated metals (toxic fumes) 2) Chrome-plated surfaces (contamination) 3) Painted surfaces (defects) 4) Oil-contaminated areas (porosity) […]

What materials do you offer for stamping?

What Metal Materials Can You Choose for Stamping Parts? As a stamping specialist since 1993, we’ve processed over 200 metal varieties – here’s your guide to selecting the right material whether you need strength, conductivity, or corrosion resistance. We regularly stamp these 8 material categories: 1) Carbon steels (most common) 2) Stainless steels (corrosion-resistant) 3) […]

Which casting method is best?

How to Choose the Right Casting Method for Your Project? After producing millions of cast parts since 1993, we know the "best" method depends entirely on your specific requirements – there’s no universal winner. For most projects, select from these 6 primary casting methods: 1) Sand casting (most versatile) 2) Die casting (high volume) 3) […]

How do you tell if a part is casted?

How Can You Identify If a Part Was Cast? After inspecting thousands of metal components, we’ve developed reliable methods to distinguish cast parts from alternatives – crucial for quality control and reverse engineering. Look for these 6 signs of casting: 1) Surface texture variations 2) Parting lines 3) Gate/runner marks 4) Draft angles 5) Internal […]

What kind of sand is used for casting?

What Types of Sand Are Used in Metal Casting? After three decades in metal casting, we’ve tested hundreds of sand formulations – the right mix makes all the difference between success and scrapped parts. Foundries primarily use silica sand (90-98% SiO2), chromite sand (for heat resistance), zircon sand (for precision), and olivine sand (for steel) […]

How to make a casting part?

How Are Casting Parts Manufactured Step-by-Step? At our foundry, we’ve produced over 2 million casting parts by perfecting these key manufacturing stages. The casting process transforms molten metal precisely into functional components. The casting process involves pattern creation, mold preparation, metal melting, pouring, solidification, removal, and finishing – with exact steps varying based on casting […]

What are the 4 main types of casting?

What Are the 4 Main Types of Casting Processes? In our decades of metal manufacturing experience, we’ve mastered all four fundamental casting methods – each solving different production challenges with unique approaches to metal forming. Snippet paragraph: The four primary casting methods are sand casting (versatile for large parts), die casting (high-speed precision), investment casting […]

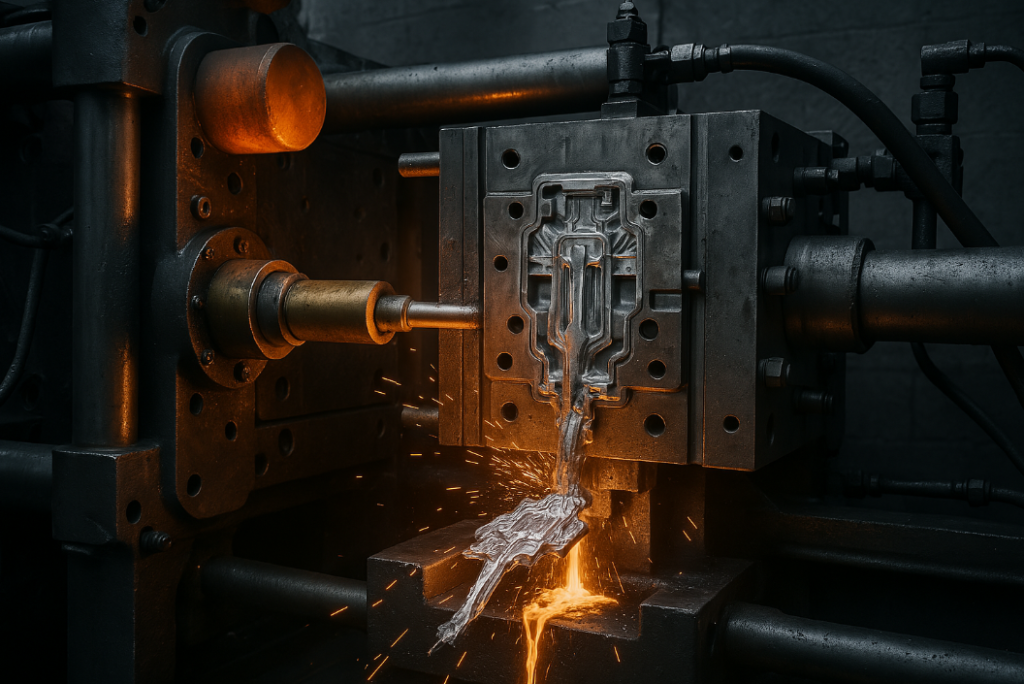

What are die casting parts?

What Are Die Casting Parts and Why Are They Essential? In our 30 years of metal fabrication, we’ve produced over 5 million die-cast components for industries ranging from automotive to consumer electronics. These precision parts solve critical manufacturing challenges. Snippet paragraph: Die casting parts are metal components created by forcing molten metal under high pressure […]

What are casting parts?

What Are Casting Parts and How Are They Used in Manufacturing? From engine blocks to plumbing fixtures, casting parts form the foundation of countless industrial products. At our ISO-certified foundry, we produce over 10,000 tons of casting parts annually for global manufacturers. Snippet paragraph: Casting parts are metal components created by pouring molten metal into […]