What welding rod to use on rusty metal?

What welding rod to use on rusty metal? Rust happens—but your welds don’t have to suffer. The best welding rod for rusty metal is E6011—it delivers deep penetration, handles poor prep, and runs on AC or DC machines. Here’s how to tackle rusted steel confidently and cleanly. What is the best rod for welding rusty […]

What are 6011 welding rods good for?

What are 6011 welding rods good for? Need a rod that cuts through rust, dirt, and paint? 6011 welding rods are perfect for deep-penetration, all-position welding on dirty or poorly prepared steel—ideal for repairs, maintenance, and fieldwork. Here’s how 6011 compares to other rods and where it works best. What rod is better, 6011 or […]

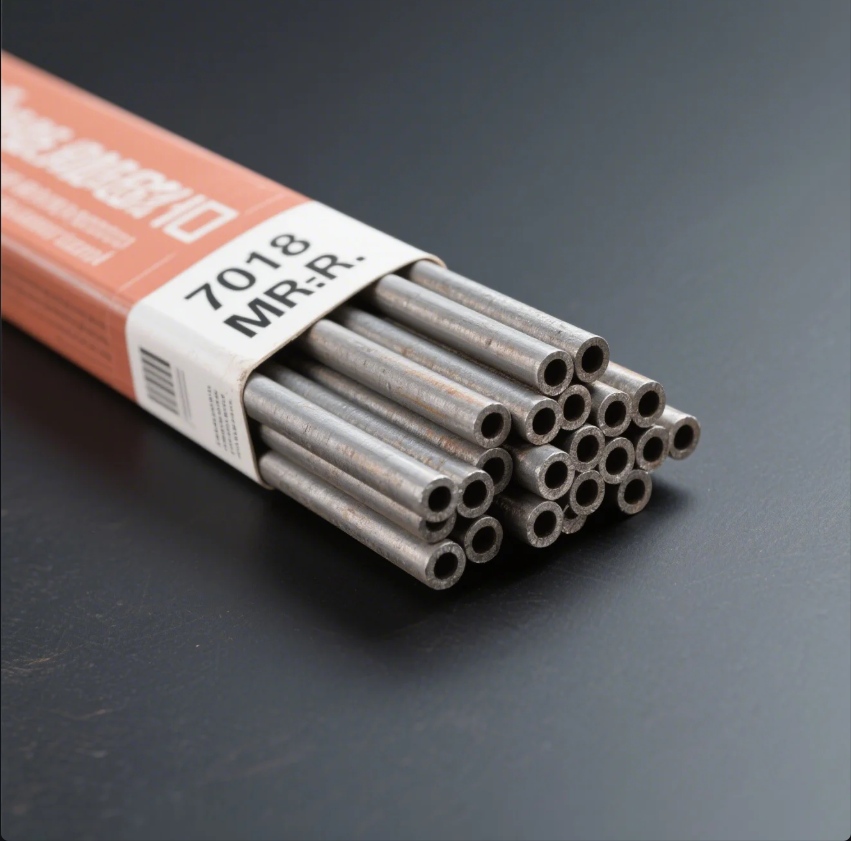

What is 7018 MR welding rod used for?

What is 7018 MR Welding Rod Used For? Table of Contents What is a 7018 rod good for? What is 7018 MR? What are 7014 welding rods used for? What are 6011 welding rods used for? How to choose the right welding rod for your project? Best practices for welding rod storage and handling Why […]

What is the world’s longest continuous weld?

What is the world’s longest continuous weld? Welding isn’t just about short seams—some projects span miles. The world’s longest continuous weld is believed to be over 3,500 meters (11,500 feet), completed on massive offshore pipelines or pressure vessels during uninterrupted orbital welding operations. Let’s explore the scale, skill, and science behind these record-breaking welds. What […]

What is the hardest rod to weld with?

What is the hardest rod to weld with? Some rods test your technique more than your machine. E6010 is widely considered the hardest welding rod to use—it has a fast-freeze puddle, unstable arc, and demands precise control. Let’s see why it’s challenging, how it compares to others, and what welders need to master it. What […]

What is super 1000 welding rod used for?

What is Super 1000 welding rod used for? Need a rod that works on almost anything—even without perfect prep? The Super 1000 welding rod is a general-purpose maintenance electrode used for welding dissimilar metals, dirty surfaces, and emergency repairs—without the need for exact fit-up or clean base material. Let’s explore how it compares to traditional […]

Why do welders bend their rods?

Why do welders bend their rods? Welding in tight spots takes more than skill—it takes creative rod control. Welders bend their rods to reach awkward positions, improve torch angles, or avoid arc blow—especially in pipe welding and hard-to-access joints. Here’s why it’s a smart technique, and how it improves precision and safety. Why do pipeline […]

What is 316 welding rod used for?

What is 316 welding rod used for? Need corrosion resistance in harsh, industrial settings? The 316 welding rod is used to weld 316 and 316L stainless steel—especially where resistance to chemicals, saltwater, or high temperatures is critical. Here’s how it compares to other stainless rods, and when to choose it. What is the difference between […]

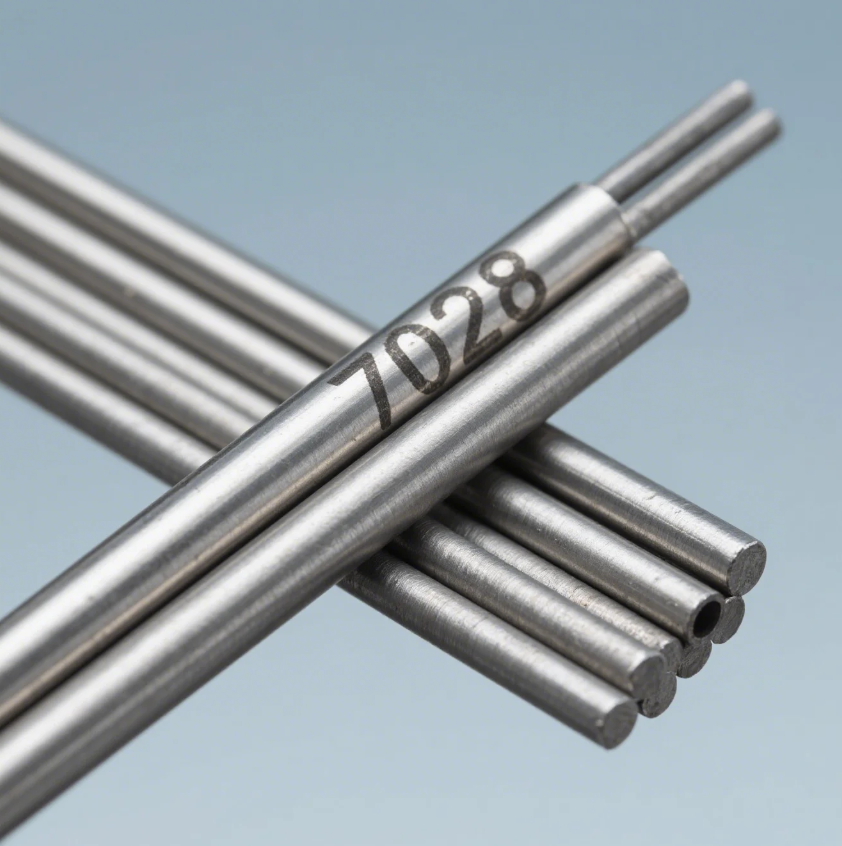

What is a 7028 welding rod used for?

What is a 7028 welding rod used for? Need speed and strength for flat welding? The 7028 welding rod is used for high-deposition, flat-position welding on heavy steel—ideal for structural work, manufacturing, and thick plate fabrication. Let’s compare 7028 with similar rods, and see where it performs best. What is 7028 welding rod used for? […]

Should I use thick or thin welding rods?

Should I use thick or thin welding rods? Using the wrong rod thickness causes poor fusion or burn-through. Welding rod thickness should match base metal thickness, welding position, and power output—thicker rods need higher amperage and deliver deeper penetration. Let’s find the right size rod for your job. What thickness of welding rod to use? […]