What is a 7014 welding rod used for?

What is a 7014 welding rod used for? Need smooth, clean welds with minimal prep? The 7014 welding rod is used for welding clean, mild steel in flat, horizontal, and vertical positions—ideal for fabrication, repairs, and ornamental welding. Let’s dive into what makes 7014 unique, and how it compares to other popular rods. What is […]

Should you push or pull stick welding?

Should you push or pull stick welding? Weld direction impacts strength, control, and penetration. In stick welding, the pull technique is almost always recommended—it gives better visibility, control, and weld penetration. Let’s break down why pulling wins, and when to make exceptions. Do you push or pull with a stick welder? This choice defines how […]

What is the most universal welding rod?

What is the most universal welding rod? Looking for one rod that works in almost any situation? The most universal welding rod is E6011—it runs on AC or DC, cuts through rust, and handles repairs, fabrication, and fieldwork alike. Let’s compare options and find the best all-around welding solution for your needs. What welding rod […]

What is 6011 rod used for?

What is 6011 rod used for? Need a rod that cuts through rust and dirt? The 6011 welding rod is a versatile stick electrode used for deep penetration, dirty metal, and outdoor repairs—especially when using AC welders. Let’s look at when to use it, how it compares to others, and why it’s a favorite in […]

Do welding rods have a shelf life?

Do welding rods have a shelf life? Welding rods don’t last forever—storage makes all the difference. Yes, welding rods have a shelf life. Moisture, air exposure, and poor storage can ruin their performance and lead to weld defects. Here’s how to tell if your rods are still good—and what to do if they’re not. How […]

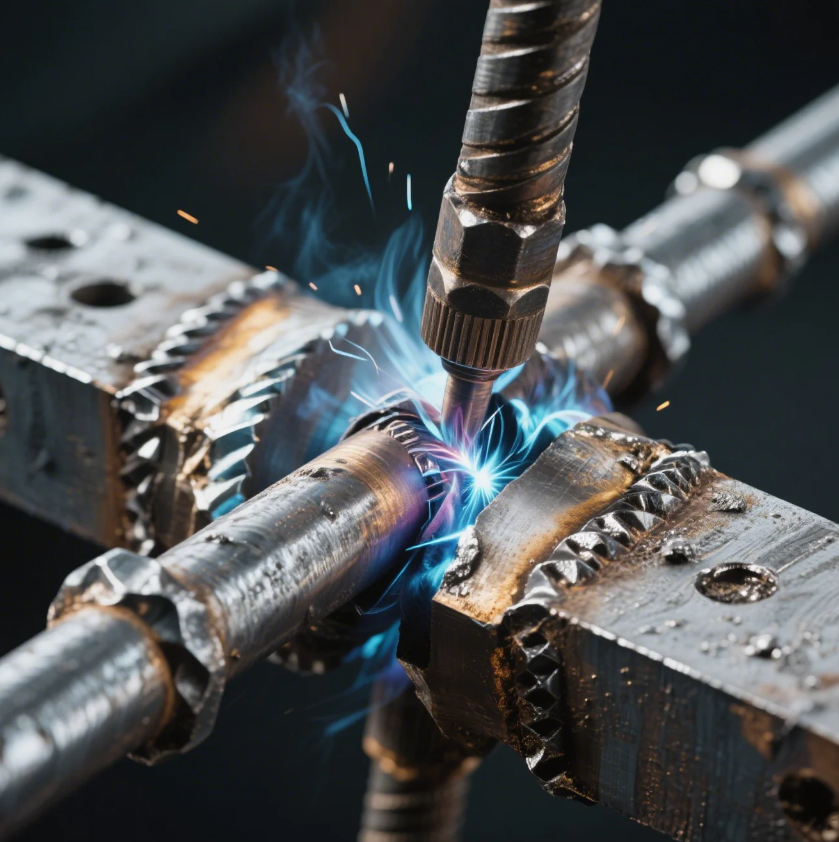

What is the hardest welding to use?

What is the hardest welding to use? Welding isn’t all sparks and speed—some methods demand real precision. TIG welding is the hardest to master due to its strict coordination, clean setup requirements, and unforgiving process window. Let’s explore what makes TIG and other advanced welds so challenging—and when they’re worth it. What type of welding […]

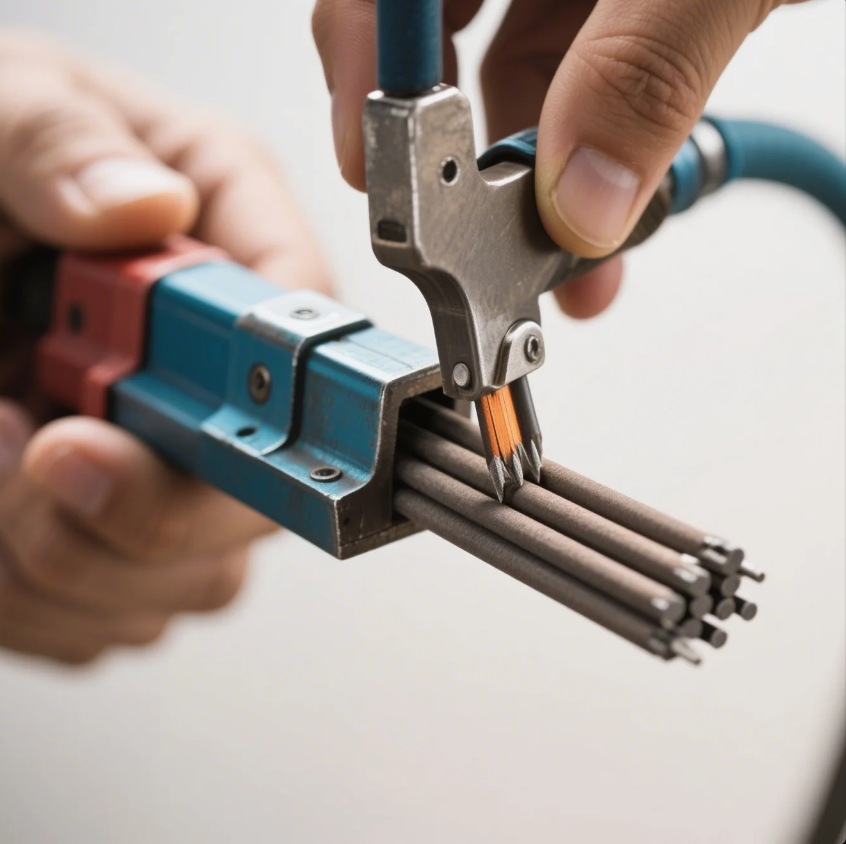

What is the easiest welding rod to use?

What is the easiest welding rod to use? Struggling with messy welds and sticking rods? The easiest welding rod for beginners offers smooth arc starts, low spatter, and great control—ideal for learning proper technique. Here’s how to pick the best rod and improve fast. What is the best welding rod for a beginner? Some rods […]

What is undercut when welding?

What is undercut when welding? Undercut ruins weld strength—even when the bead looks clean. Weld undercut is a groove melted into the base metal along the weld toe, weakening the joint and increasing failure risk. Let’s break down how to spot, prevent, and fix this critical welding defect. What causes undercut while welding? Good welds […]

What size wire do I need for aluminium welding?

What size wire do I need for aluminium welding? Using the wrong wire size causes feeding issues and weak welds. The right aluminum welding wire size depends on your current, material thickness, and wire alloy—get it wrong, and your welds will fail. Here’s how to choose the right wire for clean, strong aluminum welds. What […]

What will happen if the amperage is too high when welding?

What will happen if the amperage is too high when welding? High welding amperage causes more harm than you might expect. Excessive welding current leads to burn-through, weak welds, and increased spatter—damaging both parts and production efficiency. Let’s explore how to control amperage for cleaner, stronger welds. What happens if the amperage is too high […]