How are defects in plastic parts prevented?

How are defects in plastic parts prevented? Many buyers face costly delays due to unexpected flaws in plastic parts. Defects in plastic parts—like warpage, sink marks, or dimensional errors—can be avoided with smart design, skilled molding, and proper process control. Knowing the root causes helps you prevent wasted time, money, and product failures. Let’s break […]

What is the lead time for custom plastic parts?

What is the lead time for custom plastic parts? Many buyers struggle with delayed deliveries and vague timelines from suppliers. Lead time for custom plastic parts typically ranges from 7 to 30 days, depending on part complexity, tooling, and order volume. Fast lead times help you launch on time, restock faster, and stay ahead of […]

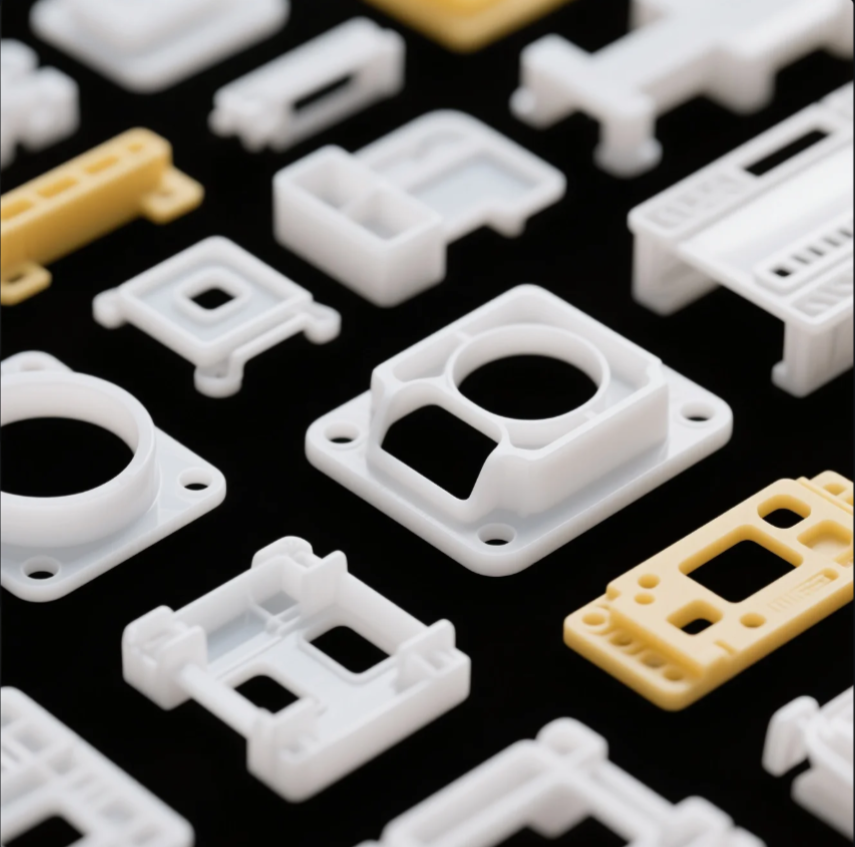

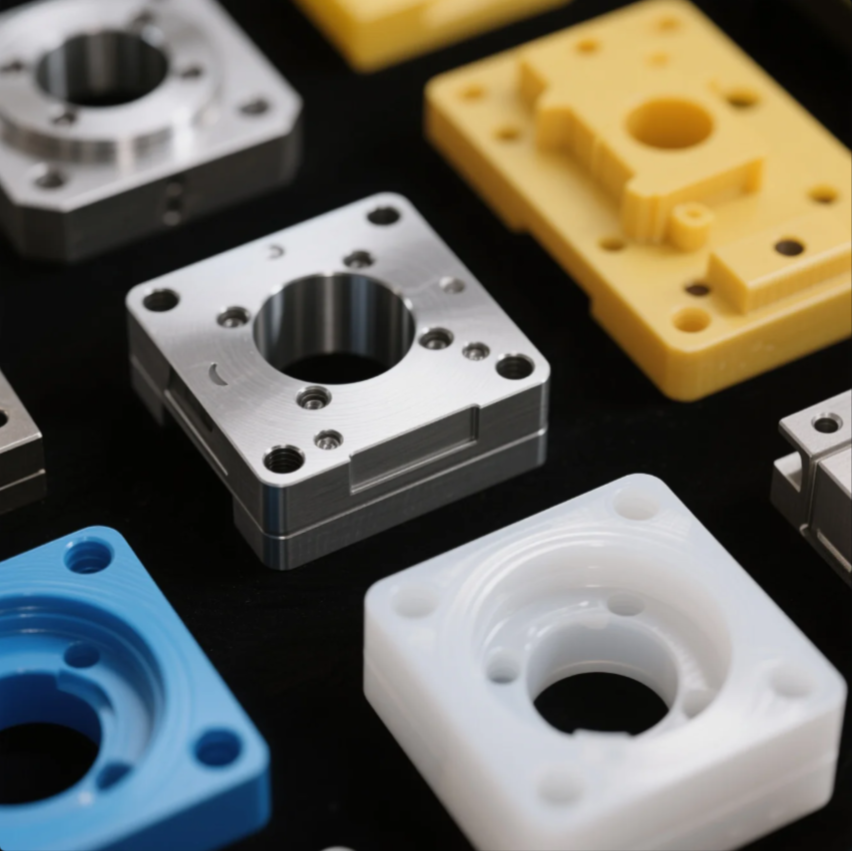

Can plastic parts be customized?

Can plastic parts be customized? Many buyers ask if plastic parts can match their exact design or branding needs. Yes, plastic parts can be fully customized in shape, color, size, function, and surface marking. Customization helps improve product fit, function, and brand identity—when done right. Let’s explore how custom plastic parts are made and what […]

Are plastic parts durable?

Are plastic parts durable? Many buyers worry if plastic parts will last under real-world use. Plastic parts can be highly durable. Their strength depends on the type of plastic, part design, and manufacturing process. Choosing the right plastic helps avoid cracking, wear, and costly replacements. Let’s explore how durable plastic really is—and where its limits […]

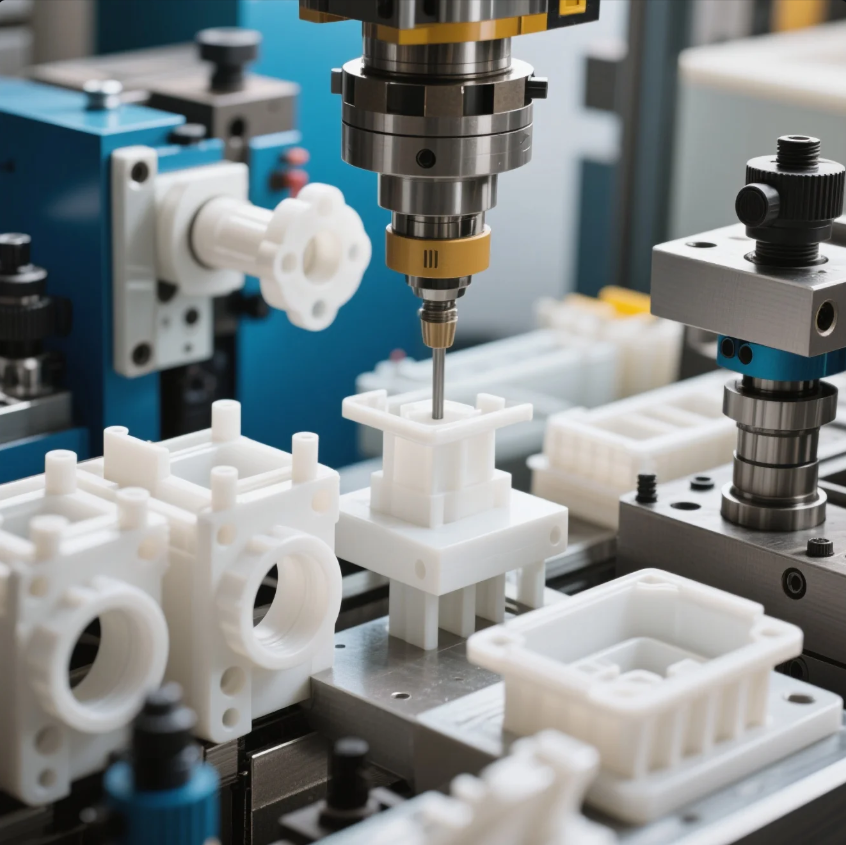

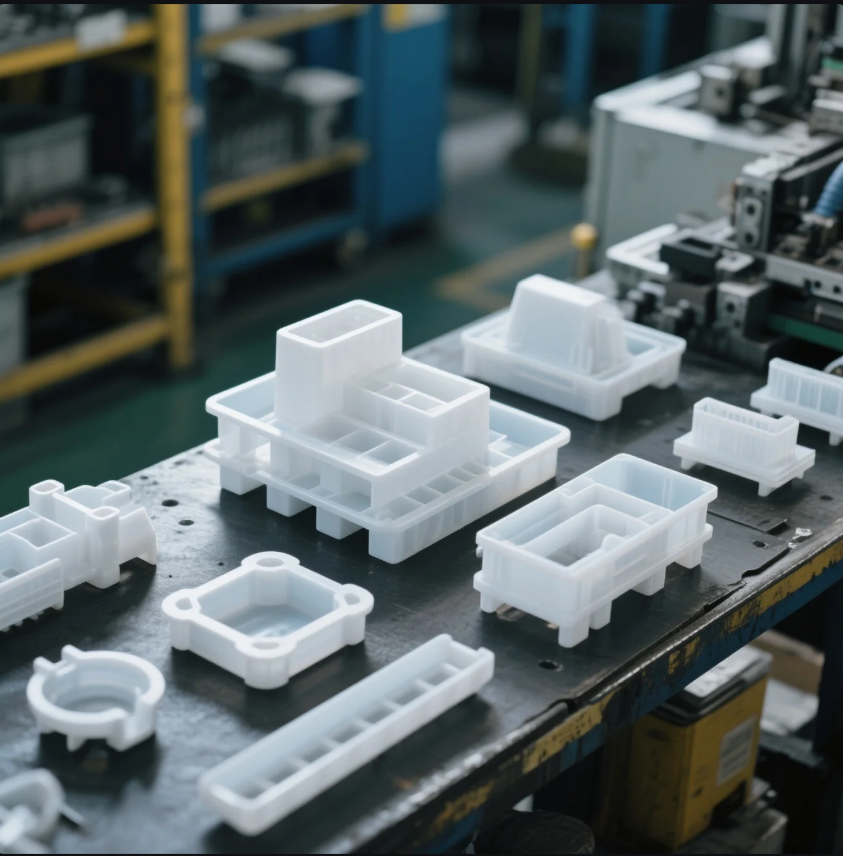

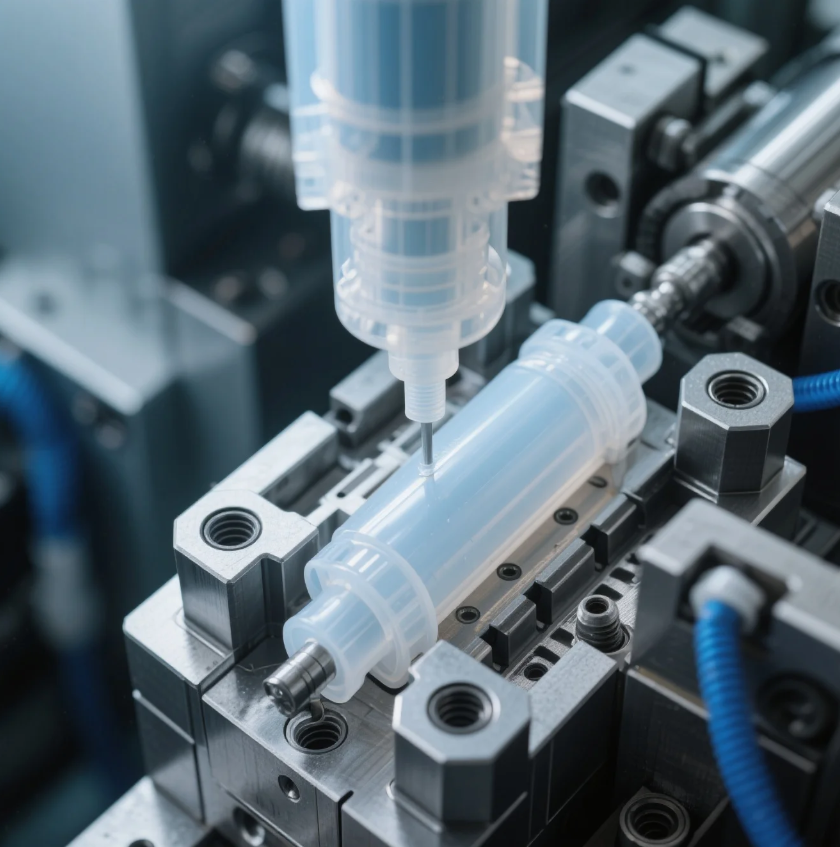

What is the most common manufacturing process for plastic parts?

What is the most common manufacturing process for plastic parts? Many buyers feel unsure about how plastic parts are made and which method fits their needs. Injection molding is the most common process for manufacturing plastic parts. It’s fast, repeatable, and ideal for mass production. Choosing the right process helps control cost, improve quality, and […]

What is the best plastic for making parts?

What is the best plastic for making parts? Choosing the best plastic often leads to confusion and costly mistakes. The best plastic depends on your product’s purpose, strength needs, and production method. Common choices include ABS, PP, PC, Nylon, and PEEK. Selecting the right plastic reduces failures, lowers cost, and improves performance. Still unsure which […]

What are plastic parts used for?

What are plastic parts used for? Plastic parts are everywhere, but choosing the right one is often confusing. Plastic parts are widely used in automotive, electronics, medical, consumer products, and packaging industries. They offer strength, flexibility, and cost-efficiency. Understanding which plastic to use helps reduce design risks and improve long-term reliability. Plastic types vary greatly, […]

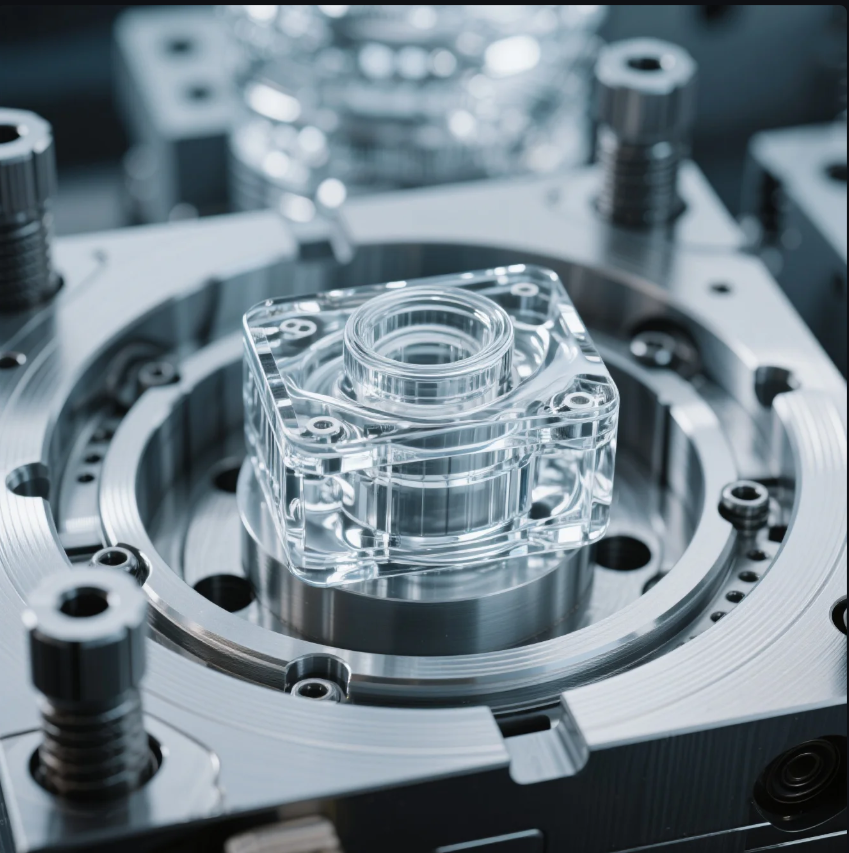

Can you injection mold glass?

Can you injection mold glass? Many clients ask whether injection molding can be used with materials other than plastic — especially glass or ceramics. You cannot injection mold pure glass, but you can mold glass-filled plastics like nylon or polycarbonate using standard molding machines. At Prime, we frequently work with glass-filled thermoplastics to produce durable, […]

What is the easiest material to injection mold?

What is the easiest material to injection mold? Many buyers want fast production with minimal issues — starting with materials that mold easily is key. Polypropylene (PP), polyethylene (PE), and polystyrene (PS) are the easiest plastics to injection mold due to their flowability and thermal stability. At Prime, we help clients choose the right resin […]

What plastic is used in injection molding?

What plastic is used in injection molding? Many buyers and engineers ask which plastic is best for injection molding — but the answer depends on strength, cost, and use case. Common plastics for injection molding include ABS, PP, PE, PC, and nylon. The choice depends on application, durability, and cost. At Prime, we guide every […]