Is injection molding a good career?

Is injection molding a good career? Many job seekers and students ask whether injection molding offers long-term career potential and good pay. Yes, injection molding is a strong career path with opportunities in production, engineering, quality control, and automation. At Prime, we’ve worked with technicians, engineers, and plant managers who’ve built stable, well-paid careers in […]

Is 3D printing better than injection molding?

Is 3D printing better than injection molding? Many clients ask whether 3D printing can replace injection molding — especially during prototyping or low-volume runs. 3D printing offers flexibility for small batches and prototypes. But injection molding is better for high-volume, cost-efficient, and durable part production. At Prime, we help businesses compare both methods and choose […]

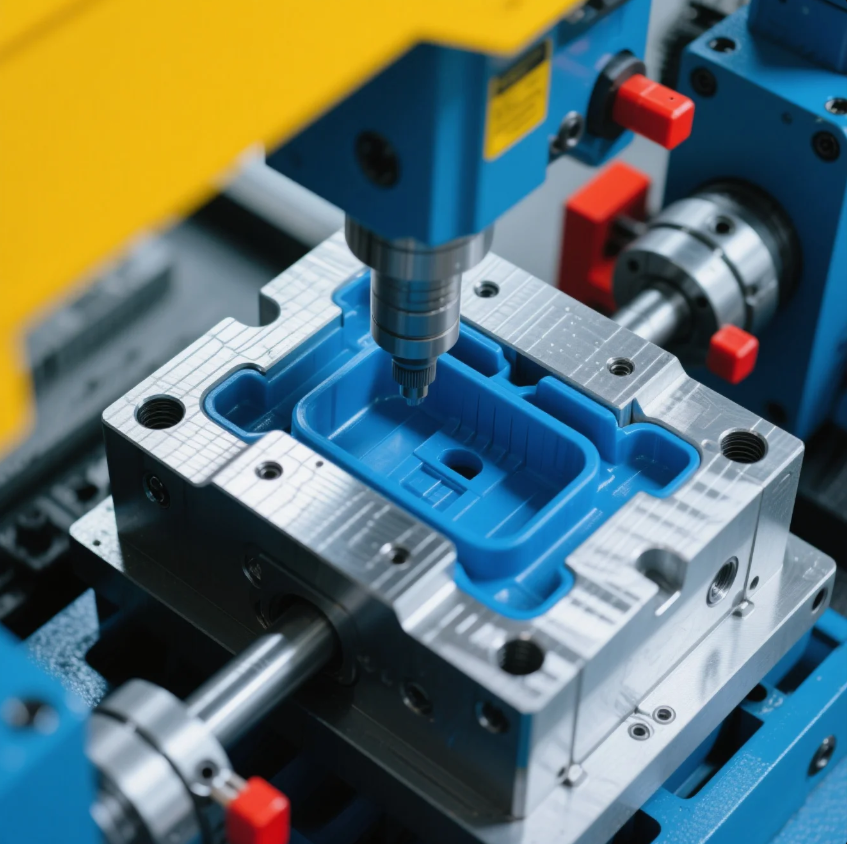

Is injection molding cheaper than machining?

Is injection molding cheaper than machining? Buyers often compare injection molding and machining for cost, especially when scaling production. Injection molding is cheaper than machining at high volumes. Machining is more cost-effective for low runs and prototyping. At Prime, we help clients choose the most cost-efficient process for every stage — from small CNC batches […]

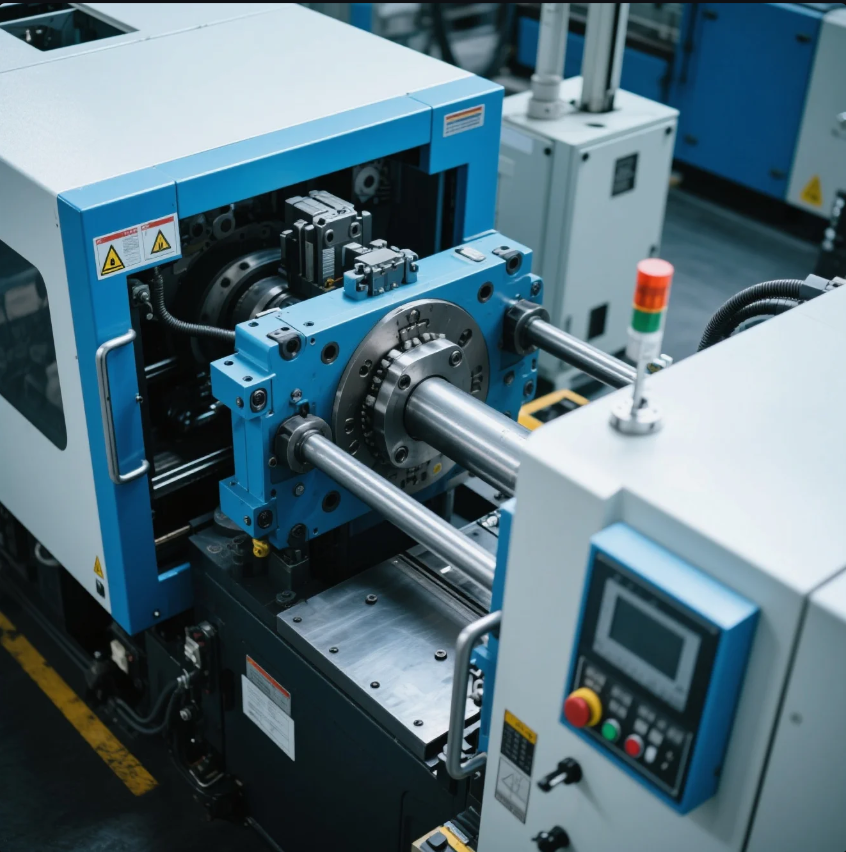

How long do injection molding machines last?

How long do injection molding machines last? Buyers often wonder how long injection molding machines will last — especially before investing tens of thousands of dollars. A well-maintained injection molding machine can last 15 to 30 years, depending on usage, quality, and maintenance. At Prime, we work with factories running both new and legacy machines. […]

Why are injection molding machines so expensive?

Why are injection molding machines so expensive? Buyers are often shocked by the high cost of injection molding machines and unsure if they’re worth the investment. Injection molding machines are expensive due to precision engineering, high-pressure systems, and automation needs. At Prime, we help clients reduce cost by offering custom plastic parts production without the […]

What is cost of injection molding?

What is the cost of injection molding? Injection molding can be cost-effective or expensive — it depends on volume, mold complexity, and part size. The total cost of injection molding includes mold creation, machine time, material, and labor. At Prime, we support global buyers by offering competitive pricing, fast delivery, and custom plastic parts manufacturing […]

How do you fix a loose threaded hole?

How do you fix a loose threaded hole? Loose threaded holes lead to unstable assemblies, stripped screws, or total joint failure. To fix a loose threaded hole, re-thread, insert a helicoil, or use thread repair compounds. Choose based on material and load. At Prime, we help clients choose the right repair method and supply precision […]

How do you install a flange nut?

How do you install a flange nut? Flange nuts are often installed incorrectly, causing slippage, damage, or joint failure. To install a flange nut correctly, ensure the flange side faces the material, and use proper torque. At Prime, we help clients avoid misinstallation by providing expert support and precise fasteners for every industrial use case. […]

What are circle clamps called?

What Are Circle Clamps Called? Many buyers describe “circle clamps” in RFQs—yet this informal term can refer to several different products. Circle clamps are typically known as hose clamps, ring clamps, or band clamps, used to secure hoses onto fittings or pipes. At Prime, we help B2B clients identify and source the exact clamp they […]

What are the different types of metal clamps?

What Are the Different Types of Metal Clamps? Many buyers simply ask for “metal clamps” in RFQs—yet they cover dozens of styles and use cases. Metal clamps are fastening devices made from steel, stainless, or aluminum used to hold objects together with force. At Prime, we help global B2B buyers source the right type based […]