How do you cut sheet metal smooth?

How do you cut sheet metal smooth? Cutting sheet metal often leaves jagged edges that are unsafe and hard to finish. To cut sheet metal smoothly, use sharp tools like aviation snips, jigsaws with metal blades, or laser cutters. Follow up with edge finishing tools for a clean result. At Prime, we use CNC and […]

How do you use a sheet metal deburring tool?

How do you use a sheet metal deburring tool? Rough edges on sheet metal are more than cosmetic—they create safety hazards and interfere with assembly. To use a sheet metal deburring tool, glide the blade along the edge or inside holes at a 45° angle to remove burrs. Apply light, steady pressure. At Prime, we […]

What is the easiest way to cut metal by hand?

What is the easiest way to cut metal by hand? Cutting metal by hand can feel tough—unless you have the right tool for the job. The easiest way to cut metal by hand is with aviation snips, a hacksaw, or a rotary tool, depending on material thickness and shape. At Prime, we advise clients on […]

What is the best tool for smoothing edges on a piece of metal?

What is the best tool for smoothing edges on a piece of metal? Rough metal edges aren’t just ugly—they can be dangerous or lead to product failure. The best tool for smoothing metal edges depends on your part size and finish need. Common tools include flap wheels, belt grinders, deburring blades, and files. At Prime, […]

How do you dull the edge of sheet metal?

How do you dull the edge of sheet metal? Sharp edges on sheet metal aren’t just unsafe—they can ruin your entire assembly. To dull the edge of sheet metal, use sanding, filing, edge rounding, or hemming to soften sharp cuts and create smooth, safe profiles. At Prime, we apply this finishing step on all cut, […]

How to deburr metal by hand?

How to deburr metal by hand? Sharp burrs on metal edges can injure workers and ruin assemblies. To deburr metal by hand, use tools like flat files, deburring blades, sandpaper, or abrasive blocks to remove sharp edges and smooth the surface. At Prime, we deburr manually for low-volume or high-detail parts, ensuring every custom metal […]

How do you smooth metal corners?

How do you smooth metal corners? Sharp corners on metal parts can lead to safety hazards and failed inspections. To smooth metal corners, use deburring tools, grinders, or rotary files to round sharp edges and ensure a clean finish. At Prime, we smooth all punched, cut, and formed parts to meet safety and quality standards—especially […]

What is the best bend radius for sheet metal?

What is the best bend radius for sheet metal? Using the wrong bend radius can lead to cracked parts, poor fits, or tool damage. The best bend radius for sheet metal is equal to the material thickness. This rule balances formability, durability, and part precision. At Prime, we use this standard on all CNC-bent and […]

How long should a hem on sheet metal be?

How long should a hem on sheet metal be? Too short a hem can lead to tearing, weak edges, or rejected parts. The hem on sheet metal should be at least 4× the material thickness. This ensures safe bending, proper closure, and structural strength. At Prime, we follow this rule across all ISO-certified sheet metal […]

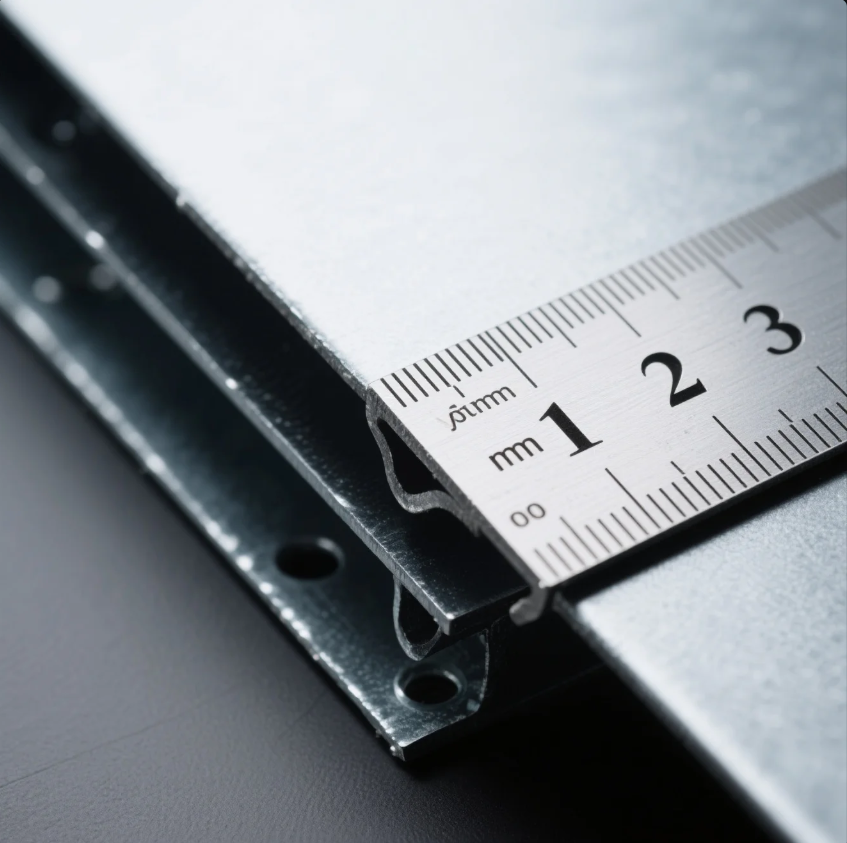

What is the minimum thickness for sheet metal?

What is the minimum thickness for sheet metal? Designing parts too thin can cause cracking, distortion, or tool failure. The minimum thickness for sheet metal is typically 0.5 mm for most applications. Below this, handling and forming become unstable without specialized equipment. At Prime, we work with materials from 0.5 mm up to 6 mm, […]