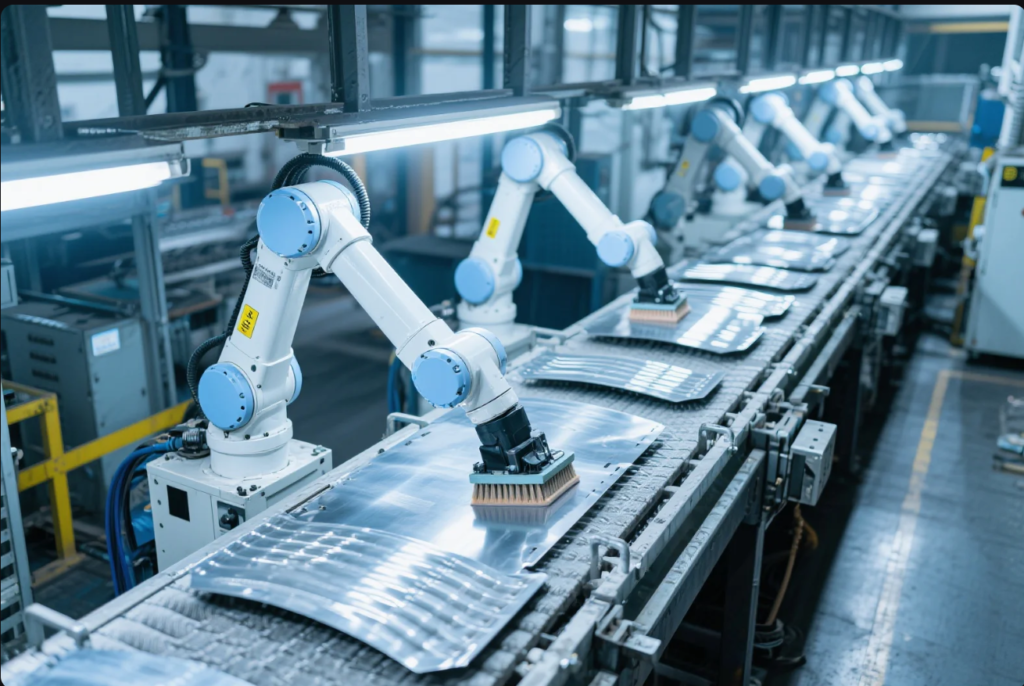

What are the processes for surface finish?

What are the processes for surface finish? No part is truly complete without the right surface finish—whether for appearance, protection, or performance. Surface finish processes are the steps used to smooth, texture, coat, or treat a component’s exterior to meet functional or aesthetic requirements. In this article, we explore the full range of finishing methods, […]

What is the difference between surfacing and resurfacing?

What Is the Difference Between Surfacing and Resurfacing? Table of Contents Introduction: Understanding the Difference What Is the Difference Between Surface and Resurface? Is Resurfacing a Parking Lot Better Than Repaving? Is Sealcoating the Same as Resurfacing? What Does Resurfacing a Driveway Mean? Frequently Asked Questions (FAQs) Conclusion Contact Us Introduction: Understanding the Difference Many […]

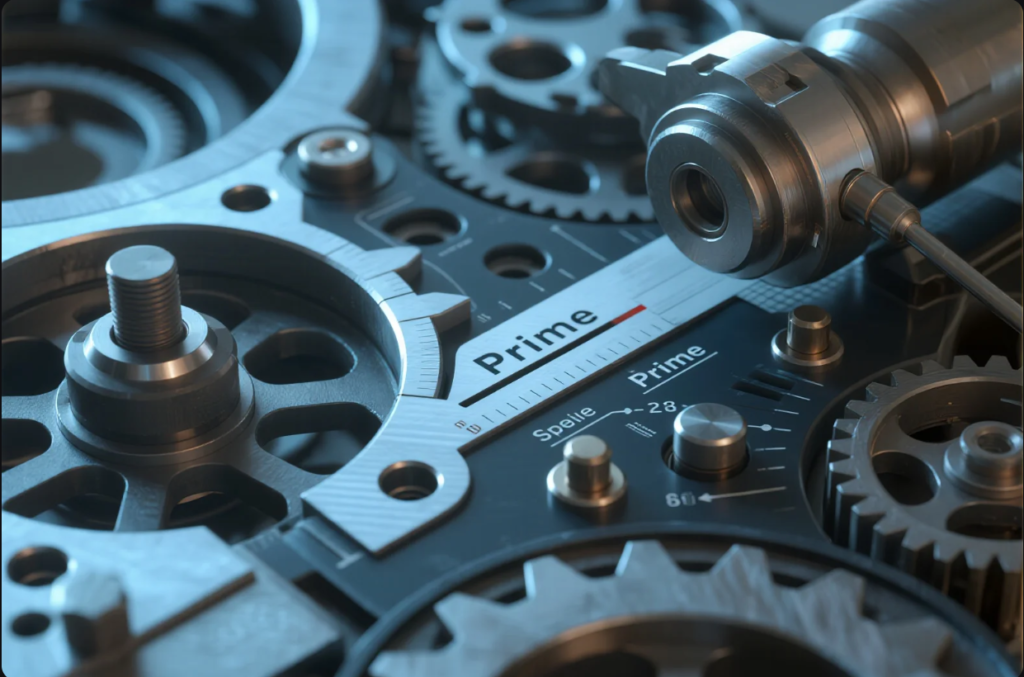

What are surface treatments and finishes?

What are surface treatments and finishes? Raw parts often aren’t ready for use—they need the right surface to resist corrosion, fit precisely, and look professional. Surface treatments and finishes refer to processes that modify or enhance the exterior of a part for protection, function, or appearance. This guide explains the difference between treatment and finishing, […]

What is the process of surfacing?

What is the process of surfacing? Surfacing is more than just polishing—it’s about transforming raw parts into precise, functional, and visually appealing components. The process of surfacing involves modifying or finishing a material’s exterior to improve accuracy, texture, durability, or optical performance. In this article, we explore how surfacing works in manufacturing and lens production, […]

What is surface treatment and surface coating?

What is surface treatment and surface coating? Metal and plastic parts don’t just need shaping—they need finishing. That’s where techniques like surface treatment and protective coatings play a critical role. These processes modify or enhance a part’s exterior to improve corrosion resistance, appearance, and long-term durability. In this article, we explain the difference between common […]

What is the surface coating process?

What is the surface coating process? Surface coating enhances part protection, color, and performance—but what exactly happens during the process? The surface coating process involves surface preparation, application of the coating material, curing, and final inspection. In this article, we’ll explain how surface coatings work, the key steps, their role compared to heat treatment, and […]

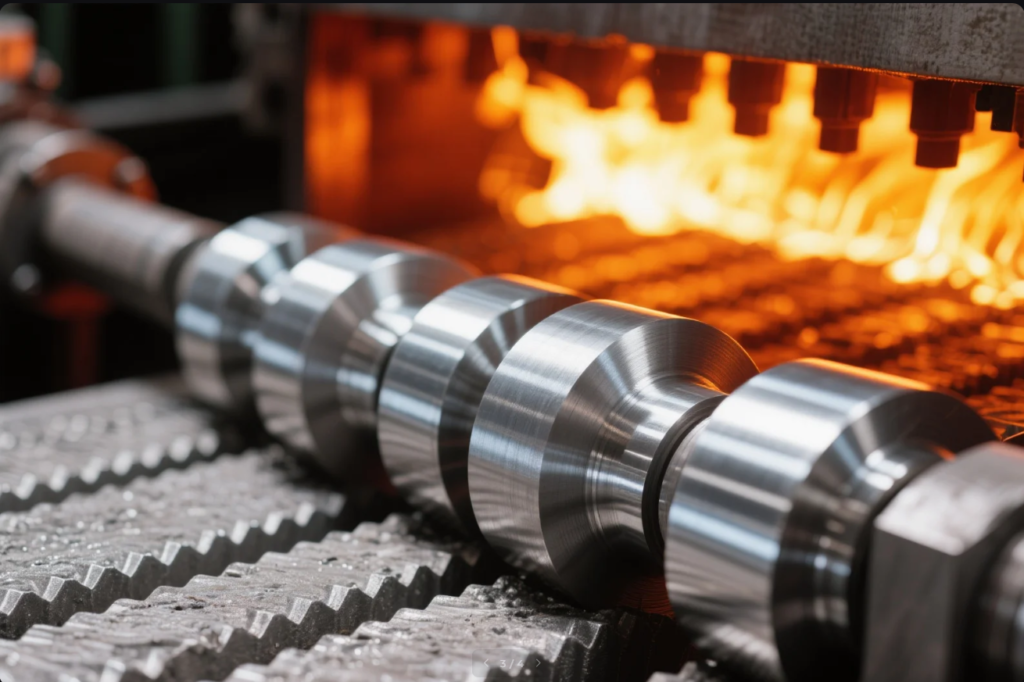

What is the surface heat treatment process?

What is the surface heat treatment process? Surface heat treatment improves metal hardness, wear resistance, and fatigue life without changing the entire part. The surface heat treatment process involves heating a metal’s outer layer to change its structure, followed by rapid cooling. In this article, we explain the steps, techniques, and advantages of surface heat […]

What is the process of surface treatment?

What is the process of surface treatment? Surface treatment improves appearance, durability, and corrosion resistance of metal and plastic parts. The process of surface treatment includes cleaning, coating, curing, and inspection. It ensures parts perform well in real-world environments. In this article, we explain how surface treatments work, their industrial types, and why they’re essential […]

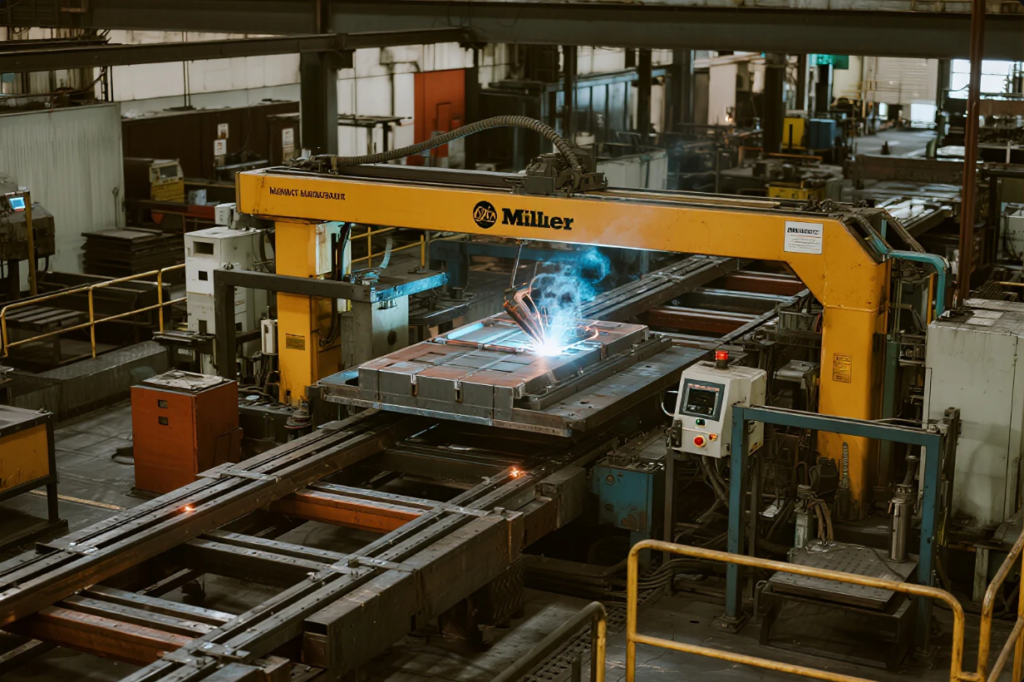

What brand of welders are made in the USA?

What Brand of Welders Are Made in the USA? Introduction: Why "Made in the USA" Matters Choosing a welder that is truly made in the USA has become a critical concern for industrial buyers, engineers, and contractors. Not only does country of origin impact product quality, warranty, and service, but it can also be crucial […]

Why are welders in high demand?

Why are welders in high demand? Welding is the hidden force behind global manufacturing—but skilled welders are getting harder to find. Why are welders in high demand? It’s because of aging workforces, rising industrial needs, and fewer young people entering the trade. In this article, we’ll answer this question from every angle. Whether you’re sourcing […]