What’s the hardest thing to weld?

What’s the Hardest Thing to Weld? Introduction: Why Welding Quality Is the Key If you buy industrial components, you know poor welding quality leads to costly rework, missed deadlines, or even failed projects. I have faced issues with suppliers unable to handle demanding welding jobs, especially with metals like titanium and cast iron. Many global […]

How to write an application for welding?

How to Write an Application for Welding? Writing a welding application? Here’s how to stand out and get hired fast. A welding application must highlight technical skills, certifications, and hands-on experience. Tailor it to match the job description. Whether you’re applying for a welding job or requesting welding services, a clear and structured application makes […]

What are the applications of welding?

What Are the Applications of Welding? Introduction: Why Welding Applications Matter in Modern Industry In today’s industrial world, welding shapes every aspect of infrastructure and product design. If you walk into a major factory, you’ll see welding robots, manual stations, and inspection labs—each essential for modern production. Reliable welding underpins the construction of bridges, power […]

What are the pros and cons of using plastic?

What Are the Pros and Cons of Using Plastic? Plastic is affordable, lightweight, and versatile—but it also raises environmental and sustainability concerns. Plastic offers flexibility, affordability, and light weight. But it also poses environmental risks and recycling challenges. Many industries rely on plastic for its cost-effectiveness and adaptability. However, its environmental impact cannot be ignored. […]

Why use plastic instead of metal?

Why Use Plastic Instead of Metal? Plastic is transforming modern manufacturing. It offers design freedom, corrosion resistance, and lower cost—all critical in today’s fast-paced industries. Plastic materials are often chosen over metal for components requiring lightweight structure, complex geometry, and electrical insulation. They are easier to process and maintain in harsh environments. In this article, […]

What are the engineering applications of plastics and polymers?

What Are the Engineering Applications of Plastics and Polymers? What are the engineering applications of plastics and polymers? This question has become central to modern manufacturing, as these materials now power everything from autonomous robotics to aerospace insulation. Engineering plastics and polymers are widely used in mechanical, structural, electrical, and thermal applications due to their […]

What are the 10 advantages of plastic?

What Are the 10 Advantages of Plastic? Plastic is everywhere—and it’s no accident. Its unique properties make it a go-to material in nearly every industry. The 10 major advantages of plastic include durability, light weight, corrosion resistance, cost-efficiency, versatility, easy molding, electrical insulation, chemical resistance, water resistance, and reusability. These benefits explain its dominance in […]

What are the 5 uses of plastic?

What Are the 5 Uses of Plastic in Industrial Applications? Plastic is one of the most versatile materials in modern manufacturing—used across nearly every industry on the planet. Plastic is used in automotive, electronics, medical, packaging, and construction industries. These applications rely on plastic’s low cost, light weight, flexibility, and ability to be molded into […]

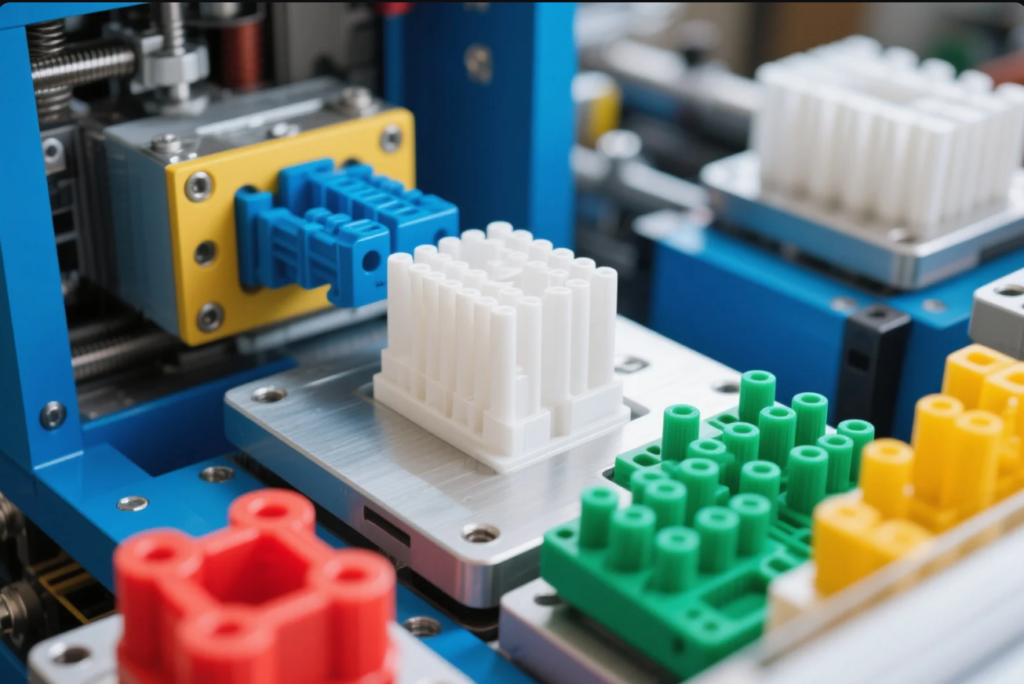

What are the applications of plastic molding?

What Are the Applications of Plastic Molding? Plastic molding is the backbone of modern manufacturing—from automotive to architecture, it\’s everywhere. Plastic molding is used to create complex plastic components for industries such as automotive, medical, electronics, construction, and consumer goods. It supports mass production with high repeatability, material efficiency, and design flexibility. This guide explores […]

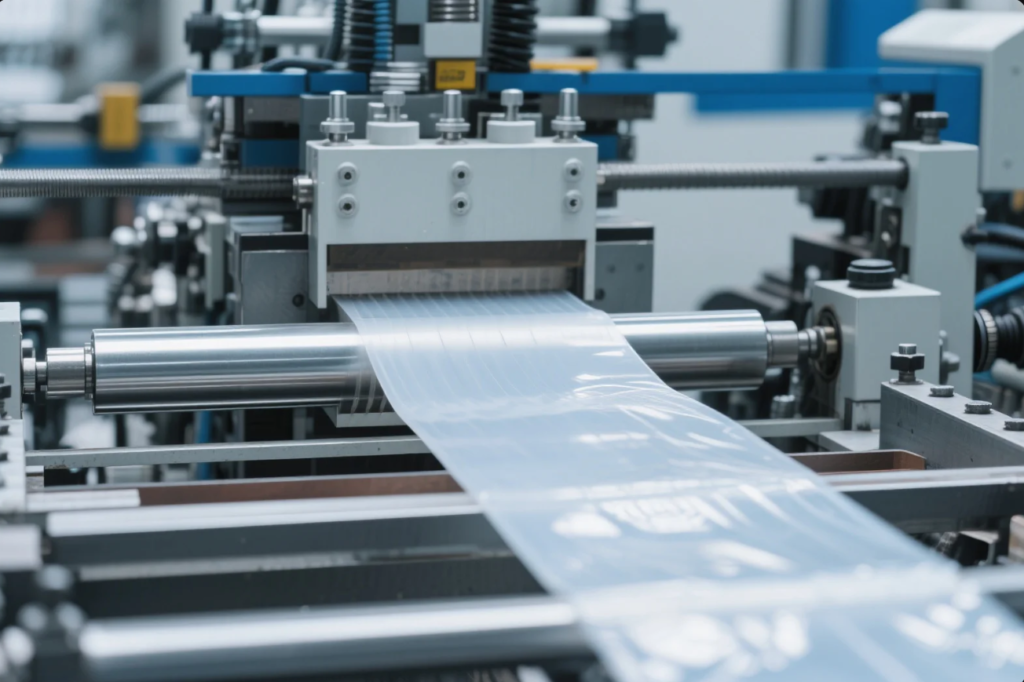

What is the process of plastic stamping?

What Is the Process of Plastic Stamping? Plastic stamping is a fast, precise, and cost-effective way to create lightweight custom parts. Plastic stamping is a manufacturing method used to shape or cut thermoplastic sheets using dies and presses. It involves steps such as material selection, die setup, heating (for hot stamping), pressing, trimming, and inspection. […]