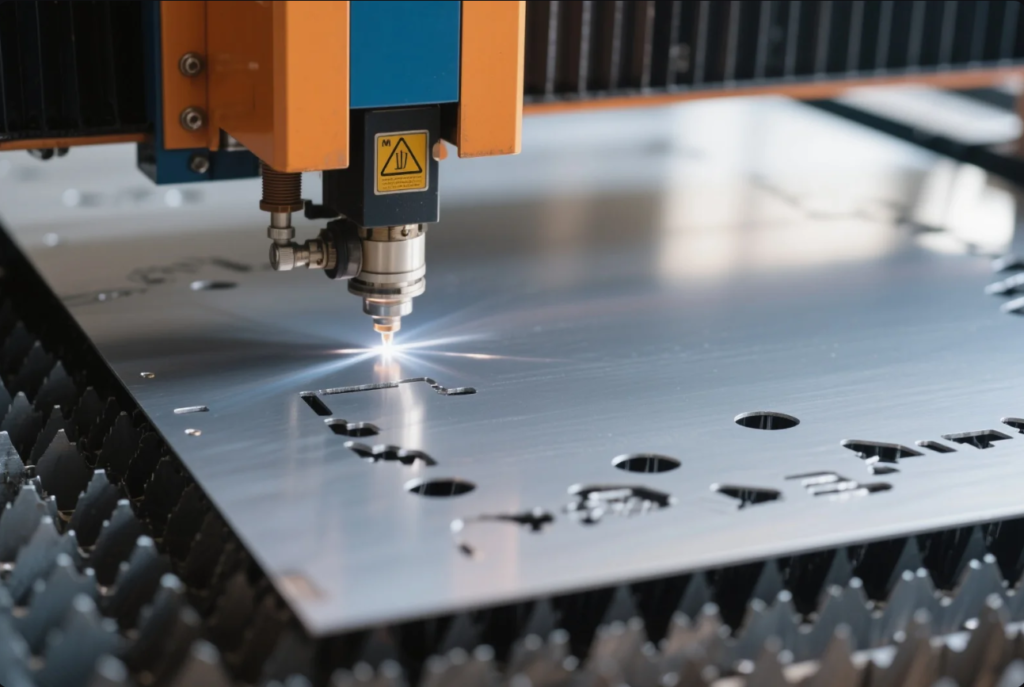

The Complete Guide to Custom Sheet Metal Parts: From Material to Finish

The Complete Guide to Custom Sheet Metal Parts: From Material to Finish Whether you’re building precision enclosures, structural components, or high-performance brackets, custom sheet metal parts are the backbone of countless industries—from automotive and aerospace to medical and electronics. This comprehensive guide walks you through every step of the custom sheet metal process, from material […]

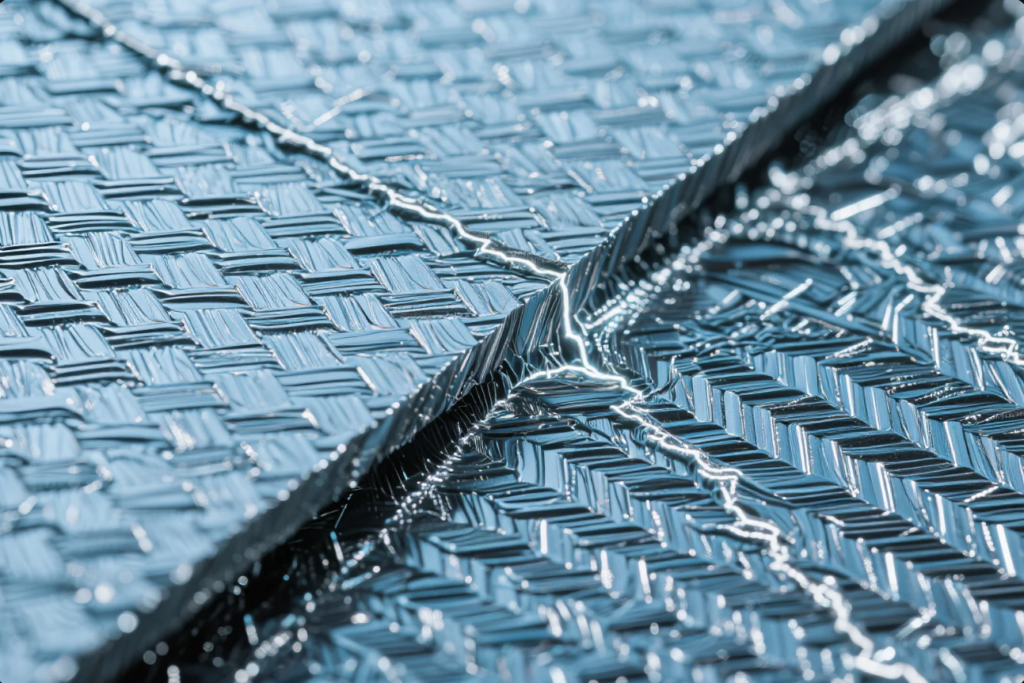

Springback in Sheet Metal Bending: How to Predict and Control It

Springback in Sheet Metal Bending: How to Predict and Control It In precision sheet metal forming, one of the most common and frustrating challenges is springback—the tendency of metal to partially return to its original shape after bending. If left unaddressed, springback can result in dimensional inaccuracies, assembly issues, and costly rework. This guide explores […]

Design for Manufacturability (DFM) in Custom Sheet Metal Components

Design for Manufacturability (DFM) in Custom Sheet Metal Components In the fast-paced world of custom sheet metal fabrication, delivering precision components at scale is only possible when the design is optimized for the shop floor. That’s where Design for Manufacturability (DFM) comes in—a critical process that helps engineers and product designers create parts that can […]

Deburring in Sheet Metal Fabrication: Techniques for Flawless Edges

Deburring in Sheet Metal Fabrication: Techniques for Flawless Edges Burrs—the rough, sharp edges left behind after cutting or punching sheet metal—may seem like a minor problem. But in high-precision manufacturing, even the smallest edge defect can lead to assembly issues, increased wear, safety risks, and failed product inspections. This guide explains what causes burrs, how […]

How to Optimize Bend Radius and K-Factor for Accurate Sheet Metal Forming

How to Optimize Bend Radius and K-Factor for Accurate Sheet Metal Forming Precision in sheet metal forming doesn’t happen by accident—it begins with a deep understanding of two critical parameters: bend radius and K-Factor. These factors directly influence the success of sheet metal fabrication by affecting formability, accuracy, material stress, and final product performance. Whether […]

2025 Trends in Metal Forging: Technology, Materials, and Sustainability

2025 Trends in Metal Forging: Technology, Materials, and Sustainability Supply chains in 2025 demand more than durability. Customers want smarter, cleaner, and lighter forged parts. As buyers shift to online channels, and regulations tighten, forging manufacturers must evolve. At Prime, we see four key trends shaping the future: smart automation, green production, next-gen alloys, and […]

Why Custom Metal Forgings Offer a Competitive Edge in 2025?

Why Custom Metal Forgings Offer a Competitive Edge in 2025? You need stronger parts. Faster lead times. Better margins. In 2025, global supply chains demand smarter sourcing. Off-the-shelf components no longer cut it. That’s where custom metal forgings shine. You get exactly what you need — no overengineering, no waste, no delays. Custom Forged Parts […]

Top 4 Metal Forging Methods Explained: Which One Fits Your Project?

Top 4 Metal Forging Methods Explained: Which One Fits Your Project? You’re sourcing metal parts. But something’s off. Quality varies. Prices swing. Deliveries miss your schedule. It could all come down to one thing—choosing the wrong forging method. You’re not alone. Many B2B buyers struggle to pick the right forging approach for their parts. But don’t worry. I’ll walk you […]

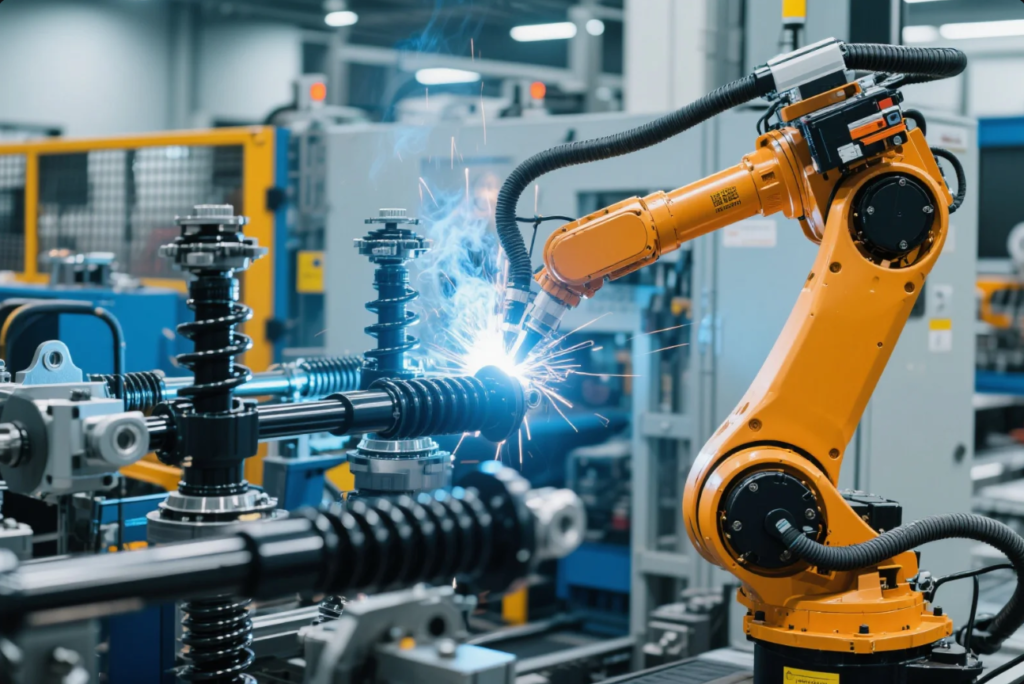

Welding Defects and How to Avoid Them in Precision Metal Parts

Welding Defects and How to Avoid Them in Precision Metal Parts I used to face defects that ruined precision welds. Then I learned how to spot and prevent them early. This guide helps you understand, inspect, and avoid typical welding problems in metal parts. Common Weld Defects: Cracks, Porosity, and Undercuts I once found cracks […]

Welded Metal Components for Automotive, Aerospace, and Industrial Equipment

Welded Metal Components for Automotive, Aerospace, and Industrial Equipment I once struggled to find welds that could withstand extreme loads. So I learned how different industries like automotive and aerospace structure their welding standards and material choices. This guide helps you build strong, reliable metal components. Snippet paragraph: High-stress industries demand welds with fatigue resistance, […]