Plastic Material Selection for High-Performance OEM Components

Plastic Material Selection for High-Performance OEM Components Introduction Selecting the right plastic for OEM parts is critical to balancing performance, cost, regulatory compliance, and manufacturability. High-performance thermoplastics such as PEEK, PPS, PA66, and PC are revolutionizing industries like aerospace, medical, automotive, and electronics. This guide helps engineers and procurement professionals evaluate and select the best […]

OEM Plastic Part Production: From DFM to Mass Production

OEM Plastic Part Production: From DFM to Mass Production Introduction Bringing an OEM plastic part to life involves far more than injection molding. It begins with design for manufacturability (DFM), flows through prototyping, tooling validation, and concludes with packaged, globally shipped final parts. This guide walks you through every stage of production — from early […]

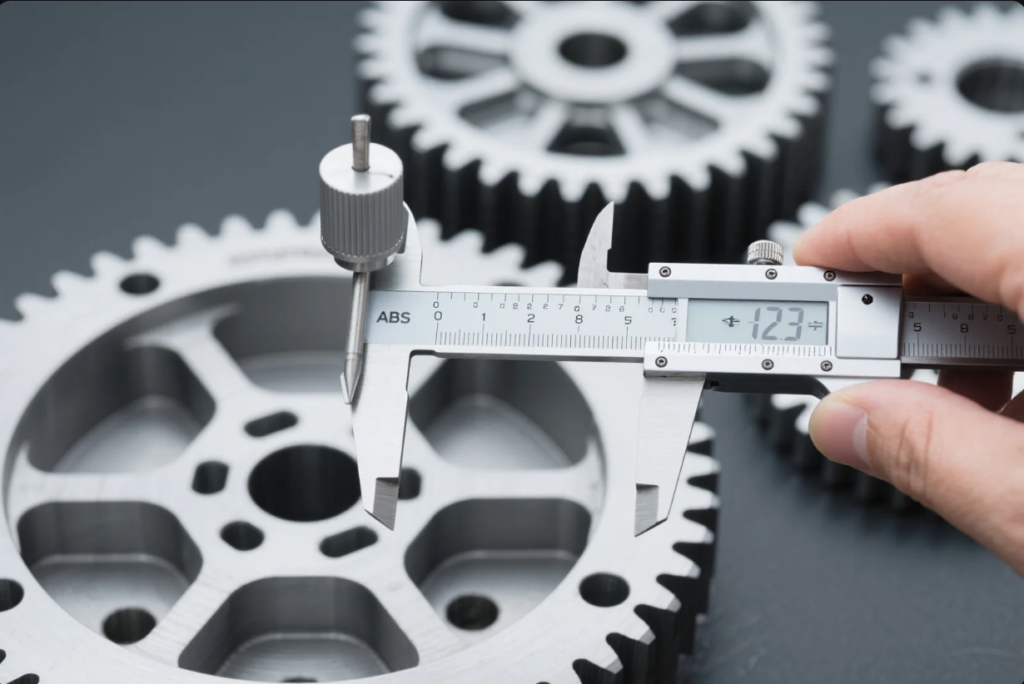

Injection Molding Tolerances & Surface Finishes Demystified

Injection Molding Tolerances & Surface Finishes Demystified Introduction Injection molding is the preferred process for high-volume plastic part production — but achieving high-quality outcomes requires tight dimensional control and attention to surface finish. This article demystifies the key tolerancing standards and surface classifications used in the industry. Whether you’re designing parts for automotive, medical, or […]

Top Plastic Materials for OEM Applications: ABS, PC, PEEK & More

Top Plastic Materials for OEM Applications: ABS, PC, PEEK & More In OEM manufacturing, material selection directly affects product success. From low-cost parts to aerospace-grade components, the right thermoplastic can improve performance, cut costs, and simplify design. This article introduces ABS, PC, PEEK, and more — with practical insights for engineers, buyers, and designers. Introduction […]