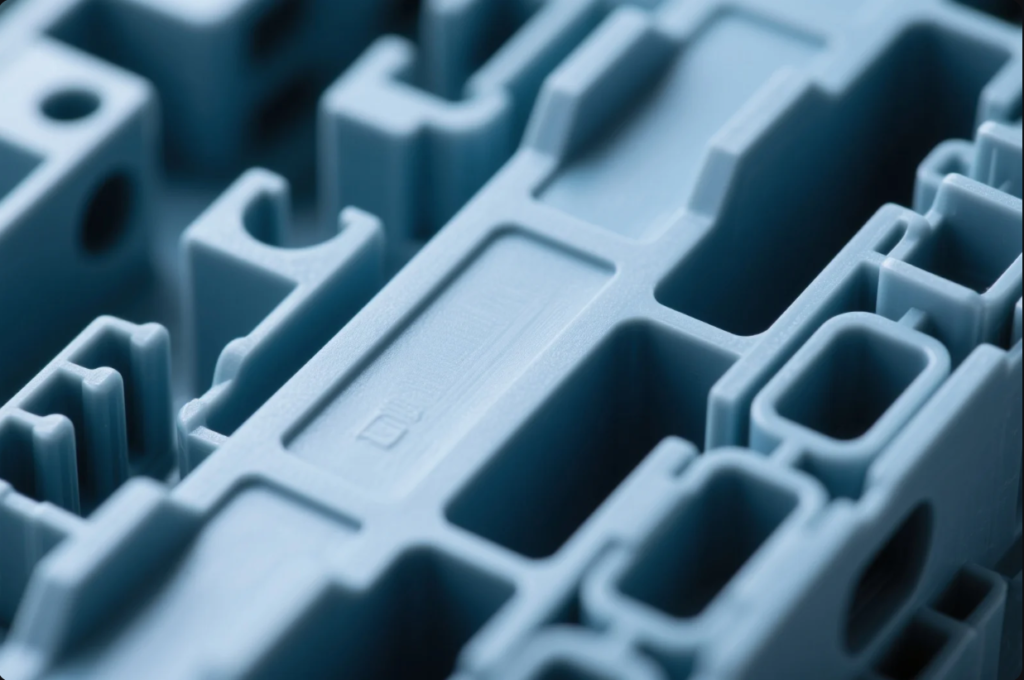

Tolerances and Surface Finishes in Plastic Injection Molding: What Engineers Must Know?

Tolerances and Surface Finishes in Plastic Injection Molding: What Engineers Must Know? Designing injection-molded plastics requires understanding tolerances and finishes—these define functionality, aesthetics, cost, and manufacturability. Knowing standard vs. precision tolerances, SPI surface grades, cosmetic vs. functional finishes, and inspection protocols helps engineers reduce defects and optimize designs. This guide walks through each topic with […]

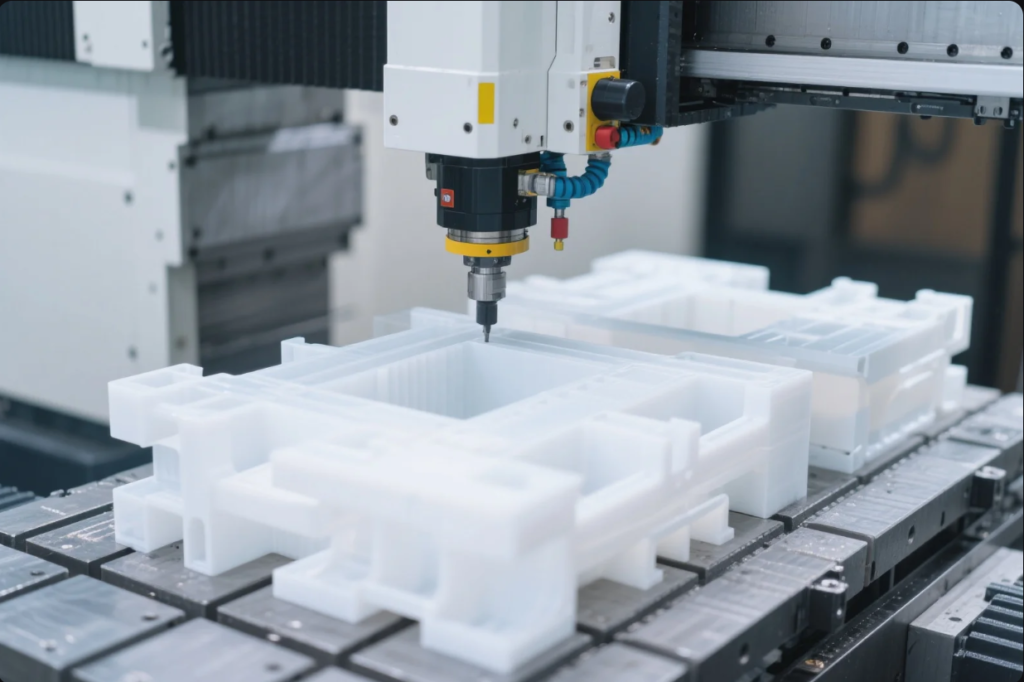

Plastic Prototyping Methods: CNC Machining vs. 3D Printing vs. Soft Mold Tooling?

Plastic Prototyping Methods: CNC Machining vs. 3D Printing vs. Soft Mold Tooling? Selecting the right prototyping method impacts speed, cost, and validation for final production. Choosing between CNC machining, 3D printing, and soft tooling depends on desired precision, material properties, and volume. This guide dives into each method, compares their advantages, and explains how to […]

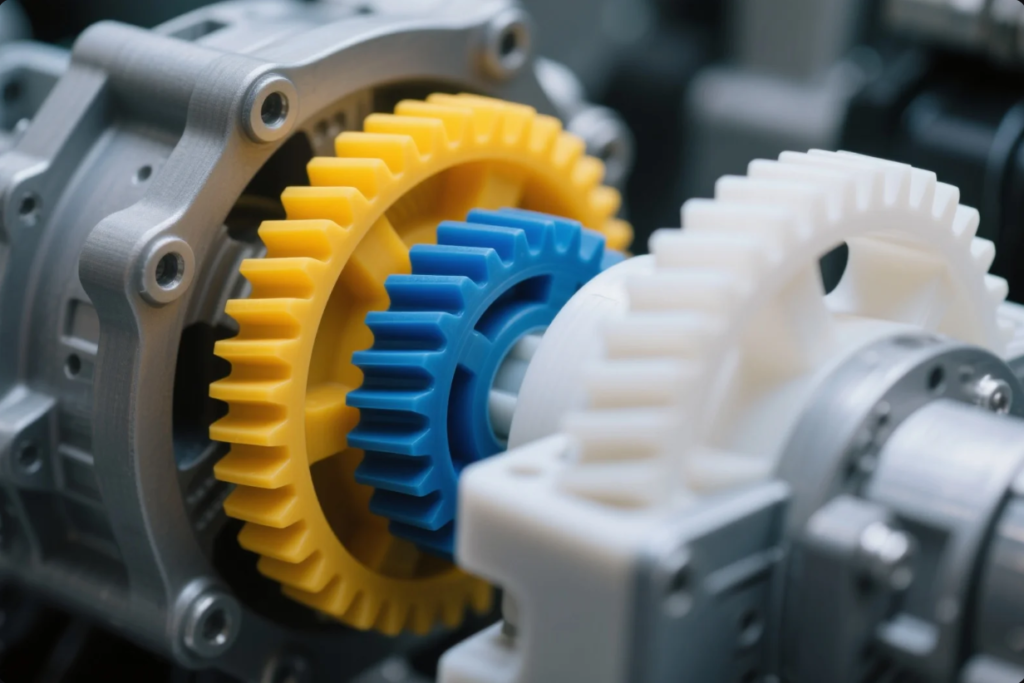

High‑Performance Engineering Plastics: Nylon, PPS, and PC in Modern Industries?

High‑Performance Engineering Plastics: Nylon, PPS, and PC in Modern Industries? When industries push limits—higher heat, greater stress, chemical exposure—standard plastics like ABS fall short. Engineering plastics such as PC, PA, PPS, and PAEK deliver superior strength, thermal stability, and chemical resistance. This guide compares major resins, explores EV and automotive applications, outlines best practices, and […]

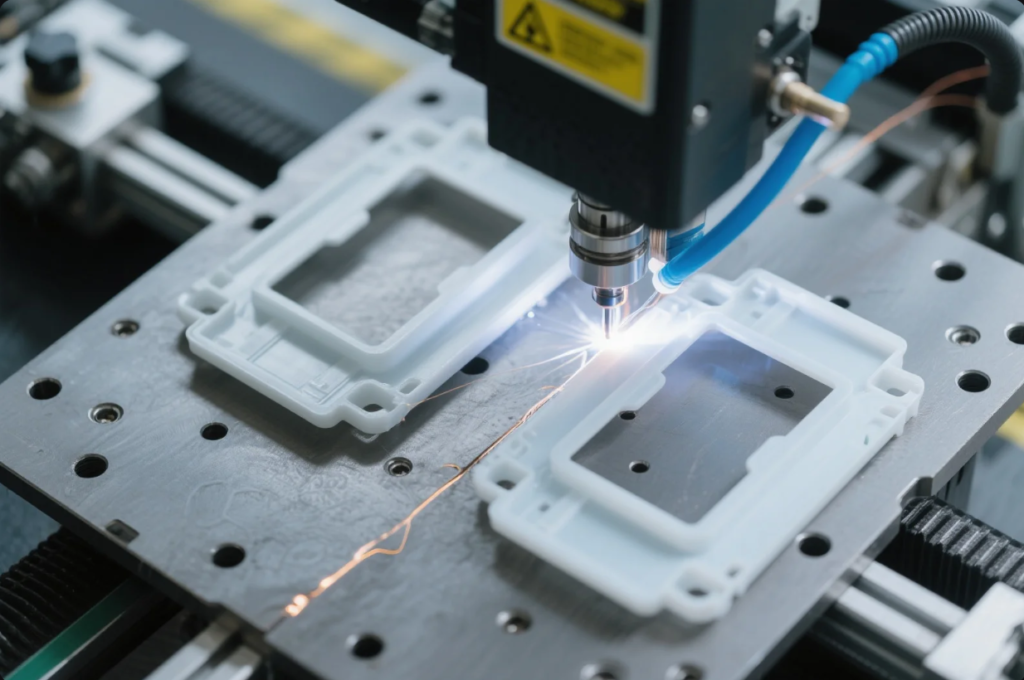

Post-Processing for Injection Molded Parts: Finishing, Welding, and Testing Explained?

Post-Processing for Injection Molded Parts: Finishing, Welding, and Testing Explained? Injection molded parts often need extra steps—welding, surface treatment, testing, and validation—to meet performance, aesthetics, and regulatory requirements. Selecting optimal post-processing ensures functional reliability, brand impact, and market compliance. Let’s explore welding options, finishing techniques, testing protocols, and certification essentials. Ultrasonic welding vs. hot plate […]

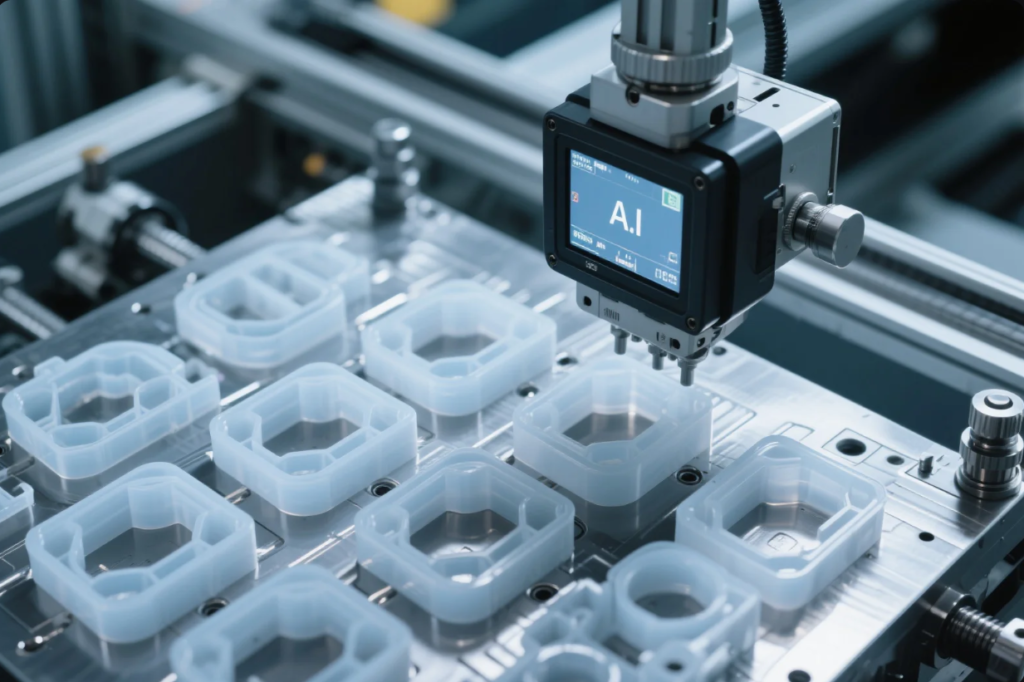

Smart Manufacturing for Plastic Parts: AI, Automation, and Quality Control?

Smart Manufacturing for Plastic Parts: AI, Automation, and Quality Control? In plastic part production, inefficiencies lead to defects, delays, and cost overruns. Smart manufacturing—leveraging IoT, AI, automated tooling, and lights-out operations—brings consistency, speed, and traceability to injection molding. Implementation delivers real-time quality control, optimized processes, and scalable output. Industry 4.0: IoT, OPC-UA, and MES redefine production […]

Sustainable Plastic Components: Biodegradable Materials and Circular Solutions?

Sustainable Plastic Components: Biodegradable Materials and Circular Solutions? I’ve heard claims about green plastics. I felt lost in jargon and supplier buzzwords. Biodegradable materials like PLA, PHA, PBS, and PBAT—coupled with mechanical, chemical, and enzymatic recycling strategies—enable a circular, compliant, and cost-effective value chain. This deep-dive guide covers material science, regulations, certifications, recycling methods, and […]

How to Choose the Right Injection Molded Plastic Parts Manufacturer?

How to Choose the Right Injection Molded Plastic Parts Manufacturer? I’ve struggled with unreliable plastic parts suppliers before. Injection molded plastic parts require precision, speed, and quality. Choosing the right supplier ensures your project succeeds. I used to experience frequent delays and defective products due to poor supplier selection. These issues disrupted production, hurt customer […]

Standardization in Metal Stamping Dies: Why It Matters

Standardization in Metal Stamping Dies: Why It Matters Modular die components: Benefits for tooling consistency Standard modules such as punch blocks, stripper plates, and guide pillars simplify sourcing and reduce lead time. Industries like automotive and consumer electronics rely on systems from Meusburger and MISUMI to ensure consistent fit and performance. Key Benefits: Faster repairs […]

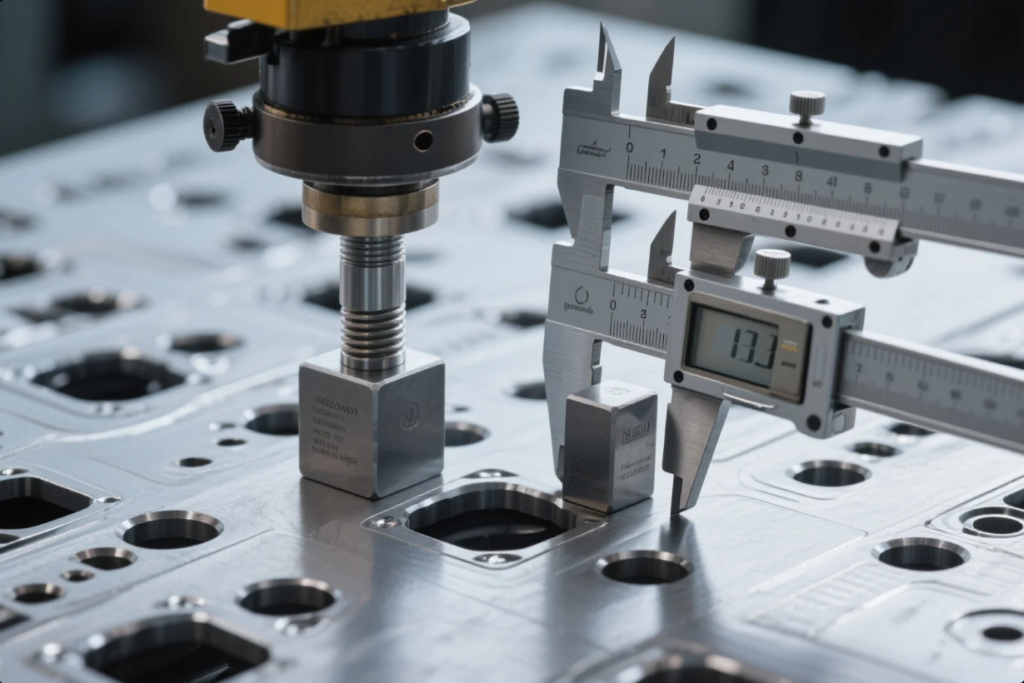

Stamping Die Maintenance: Ensuring Precision in Every Part

Stamping Die Maintenance: Ensuring Precision in Every Part How stamping tolerance affects die accuracy Stamping to a tolerance of ±0.02 mm is essential for ISO 2768 and automotive standards such as IATF 16949. Small deviations from die wear or press misalignment can cause part rejection, assembly issues, and increased scrap costs, as documented by MetalForming Magazine […]

Progressive Die Design: Boosting Efficiency in Metal Stamping?

Progressive Die Design: Boosting Efficiency in Metal Stamping? What is a progressive die? Step-by-step process explained A progressive die performs multiple operations along a strip of metal in one stroke. Each station forms, punches, bends, or trims. This results in near-finished parts at the end of the strip—ideal for high-volume efficiency. This differs from B‑punch […]