OEM Metal Casting Parts: What Engineers Must Know Before Ordering

OEM Metal Casting Parts: What Engineers Must Know Before Ordering Ordering OEM metal casting parts without technical understanding leads to tolerance errors, delayed lead times, and failed inspection reports. This ultimate guide for engineers covers every critical step in OEM casting—from CAD drawing preparation and tolerance management to standards, post-processing, and real-world examples. Based on […]

Top 10 Metal Casting Materials: Pros, Cons, and Applications You Must Know

Top 10 Metal Casting Materials: Pros, Cons, and Applications You Must Know Selecting the wrong metal can ruin your casting project before it starts. From aluminum to stainless steel and ductile iron, each casting material has distinct traits. This guide breaks down the top 10 materials used in industrial casting, including when, where, and why […]

Die Casting vs. Investment Casting: A Complete Comparison for Industrial Buyers

Die Casting vs. Investment Casting: A Complete Comparison for Industrial Buyers Choosing the wrong casting method results in wasted budget and poor product performance. Die casting and investment casting serve different industrial goals. One suits high-volume, precise applications. The other offers design flexibility and superior finishes. This guide compares them side by side. If you’re […]

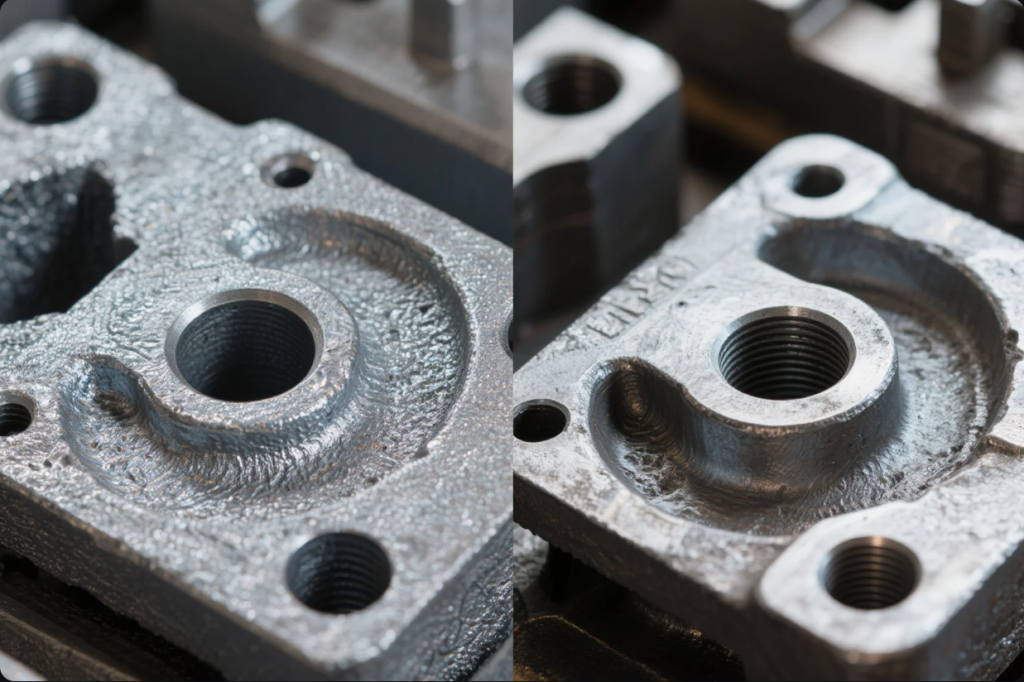

Custom Metal Casting Parts: How to Choose the Right Process for Your Project?

Custom Metal Casting Parts: How to Choose the Right Process for Your Project? Making the right casting decision prevents quality loss and missed deadlines. Each casting method has clear advantages. Sand casting offers flexibility. Die casting ensures consistency. Investment casting provides precision. Choose based on part design, volume, and cost. Selecting a poor method increases […]