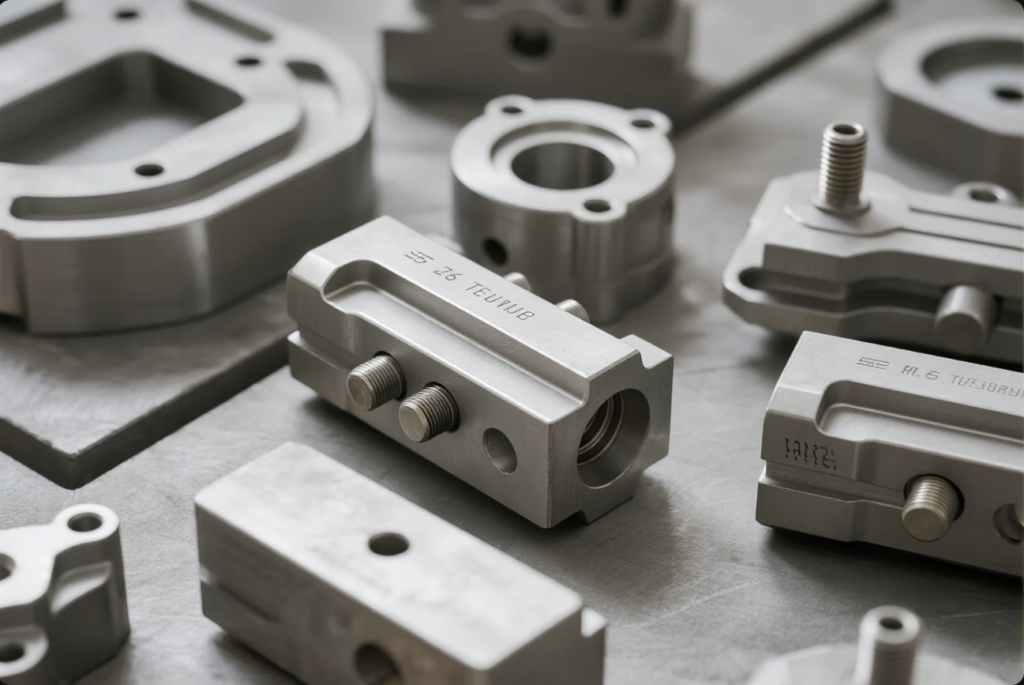

What Are the Best Practices for Designing Custom Metal Stamping and Deep Drawn Components?

What Are the Best Practices for Designing Custom Metal Stamping and Deep Drawn Components? Sourcing high-quality custom stamped and deep drawn parts is a challenge for every engineer or buyer, whether you’re supporting automotive, aerospace, electronics, or emerging energy applications. Poor design, overlooked secondary processes, and supplier miscommunication drive up costs and result in late […]

How Can I Achieve High Precision in Metal Stamping and Deep Drawing Parts?

How Can I Achieve High Precision in Metal Stamping and Deep Drawing Parts? Many buyers face frustrating delays, unstable part quality, or communication issues when sourcing high-precision stamped or deep drawn metal parts. Even experienced procurement teams struggle to balance cost, quality, and speed in a global supply chain. To achieve high precision in metal […]