Top 10 Welding Parts Manufacturers in 2025: Capabilities, Expertise, and Selection Criteria?

Choosing the right welding parts manufacturer is crucial for ensuring product quality, meeting delivery schedules, and maintaining competitive pricing.

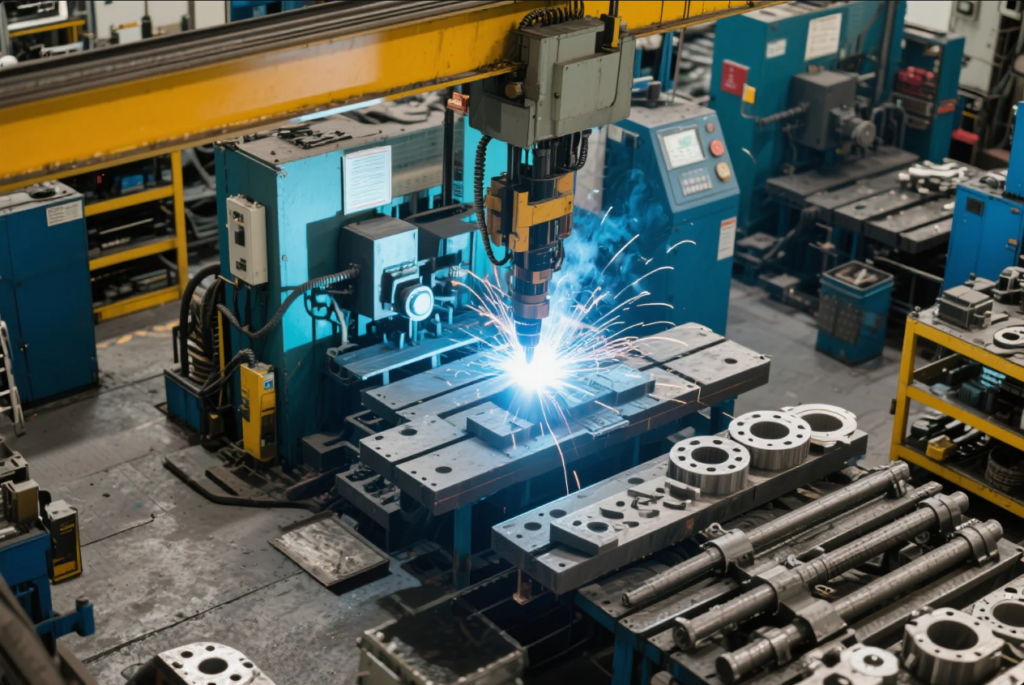

In 2025, the welding industry continues to evolve with advancements in automation, precision engineering, and global supply chain integration. Selecting a manufacturer with proven capabilities, technical expertise, and a commitment to quality is more important than ever.

Understanding the landscape of top welding parts manufacturers can help businesses make informed decisions, ensuring they partner with suppliers that align with their specific needs and industry standards.

Table of Contents

- What is the job outlook for the next 10 years for welding?

- What are the top 5 welding brands?

- What is the future of the welding industry?

- What are the 10 PPE's used in welding?

- Top 10 Welding Parts Manufacturers in 2025

- FAQs

- Conclusion

What is the job outlook for the next 10 years for welding?

The welding industry is projected to experience steady growth over the next decade, driven by infrastructure development, manufacturing advancements, and the increasing demand for skilled labor.

According to industry reports, the global welding market is expected to grow at a CAGR of 4.3% from 2025 to 2035, with significant contributions from sectors like automotive, construction, and energy.

Factors Influencing Growth

- Infrastructure Projects: Government investments in infrastructure are boosting demand for welding services.

- Technological Advancements: Automation and robotics are enhancing welding efficiency and precision.

- Skilled Labor Shortage: The industry faces a shortage of skilled welders, emphasizing the need for training and education programs.

What are the top 5 welding brands?

Several brands have established themselves as leaders in the welding industry, known for their quality, innovation, and reliability.

The top five welding brands in 2025 are:

- Lincoln Electric: Renowned for its comprehensive range of welding equipment and consumables.

- Miller Electric: Offers advanced welding solutions with a focus on user-friendly technology.

- ESAB: Known for its cutting-edge welding and cutting equipment.

- Fronius: Specializes in high-tech welding systems and automation.

- Kemppi: Offers innovative welding solutions with a focus on digitalization and connectivity.

These brands have consistently delivered products that meet the evolving needs of the welding industry, making them preferred choices for professionals worldwide.

What is the future of the welding industry?

The welding industry is poised for significant transformation, influenced by technological advancements, sustainability initiatives, and changing workforce dynamics.

Key trends shaping the future of welding include:

- Automation and Robotics: Increasing adoption of automated welding systems to improve efficiency and consistency.

- Digitalization: Integration of IoT and data analytics for real-time monitoring and quality control.

- Sustainable Practices: Emphasis on eco-friendly welding processes and materials.

- Workforce Development: Focus on training programs to address the skilled labor shortage.

These developments are expected to enhance productivity, reduce costs, and improve the overall quality of welding operations.

What are the 10 PPE's used in welding?

Personal Protective Equipment (PPE) is essential for ensuring the safety of welders. The ten commonly used PPE items in welding are:

- Welding Helmet: Protects the eyes and face from sparks and UV radiation.

- Safety Glasses: Provides additional eye protection.

- Welding Gloves: Shields hands from heat and sparks.

- Welding Jacket: Protects the upper body from burns.

- Welding Apron: Offers additional protection for the torso.

- Respirator: Filters harmful fumes and particles.

- Ear Protection: Guards against noise-induced hearing loss.

- Steel-Toe Boots: Protects feet from heavy objects and hot materials.

- Fire-Resistant Pants: Shields legs from sparks and heat.

- Welding Sleeves: Provides arm protection when a full jacket is not required.

Proper use of PPE is crucial for minimizing the risk of injuries and ensuring a safe working environment.

Top 10 Welding Parts Manufacturers in 2025

Identifying reliable welding parts manufacturers is vital for businesses seeking quality components and timely delivery. Here are the top 10 welding parts manufacturers in 2025:

-

Shandong Prime International Trade Co., Ltd.

- Overview: Established in 1993, Prime offers a comprehensive range of metal parts, including stamping, CNC, welding, casting, fasteners, and plastic components.

- Capabilities: ISO-certified, with 10 production lines and over 20 years of experience.

- Global Reach: Serves clients across North America, Europe, the Middle East, and Australia.

- Contact: [email protected]

-

- Overview: A global leader in welding products, offering a wide range of equipment and consumables.

- Capabilities: Known for its innovative solutions and commitment to quality.

- Global Reach: Operates in over 160 countries with a vast network of distributors.

-

- Overview: Offers advanced welding solutions with a focus on user-friendly technology.

- Capabilities: Provides a comprehensive range of welding equipment and accessories.

- Global Reach: Serves various industries worldwide, including manufacturing and construction.

-

- Overview: Known for its cutting-edge welding and cutting equipment.

- Capabilities: Offers a complete line of fabrication solutions for virtually every application.

- Global Reach: Operates in nearly every country with subsidiaries or agents providing sales and support.

-

- Overview: Specializes in high-tech welding systems and automation.

- Capabilities: Provides innovative welding technologies and solutions.

- Global Reach: Has a presence in over 60 countries with a strong distribution network.

-

- Overview: Offers innovative welding solutions with a focus on digitalization and connectivity.

- Capabilities: Supplies advanced products, digital solutions, and services for professionals.

- Global Reach: Operates in over 70 countries with a highly skilled partner network.

-

- Overview: Provides welding, brazing, and coating solutions with a focus on maintenance and repair.

- Capabilities: Offers a wide range of products and services for various industries.

- Global Reach: Has a presence in over 100 countries with a strong network of experts.

-

- Overview: Delivers welding consumables and equipment for various industries.

- Capabilities: Offers extensive technical consultation and individual solutions.

- Global Reach: Operates in more than 25 countries with over 50 subsidiaries.

-

- Overview: Provides advanced welding systems and automation solutions.

- Capabilities: Offers a wide range of models to meet various welding needs.

- Global Reach: Serves clients worldwide with a focus on innovation and quality.

-

- Overview: Offers a wide range of welding and cutting equipment.

- Capabilities: Known for its commitment to quality and innovation.

- Global Reach: Serves clients across various industries worldwide.

These manufacturers have demonstrated excellence in product quality, innovation, and customer service, making them top choices for businesses worldwide.

FAQs

Q1: What factors should I consider when selecting a welding parts manufacturer?

A1: Key considerations include the manufacturer's certifications (e.g., ISO), production capabilities, quality control processes, delivery timelines, and customer support.

Q2: How does automation impact the welding industry?

A2: Automation enhances welding precision, efficiency, and consistency, leading to improved product quality and reduced labor costs.

Q3: Why is PPE important in welding?

A3: PPE protects welders from hazards such as burns, eye damage, and inhalation of harmful fumes, ensuring a safe working environment.

Q4: What is the significance of ISO certification for manufacturers?

A4: ISO certification indicates that a manufacturer adheres to international quality management standards, ensuring consistent product quality and customer satisfaction.

Q5: How can I contact Prime for welding parts inquiries?

A5: You can reach out to Prime via their website primecustomparts.com or email them at [email protected] for inquiries and quotes.

Conclusion

Selecting the right welding parts manufacturer is essential for ensuring product quality, meeting project timelines, and achieving cost-efficiency. The manufacturers listed above have proven track records in delivering high-quality welding components and services. For businesses seeking a reliable partner, Shandong Prime International Trade Co., Ltd. stands out with its comprehensive capabilities, global reach, and commitment to excellence.