Top 10 CNC Parts Manufacturers in 2025: Capabilities, Expertise, and Selection Criteria?

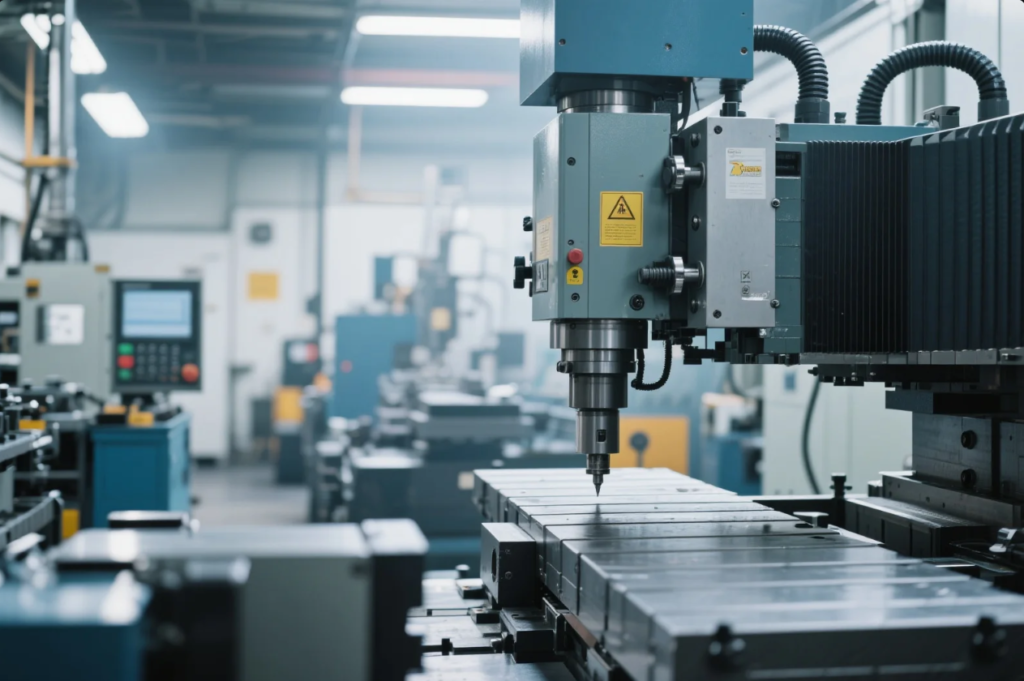

Finding a trusted CNC parts manufacturer affects every stage of production — from prototype to final assembly.

In 2025, precision, customization, and turnaround time define CNC manufacturing excellence. This guide lists the top CNC parts suppliers worldwide, and explains what makes a reliable, scalable, and ISO-certified CNC partner.

Whether you're sourcing aluminum housings or complex multi-axis steel parts, the right supplier ensures consistent quality and cost control. Let’s break down how to choose the best.

Table of Contents

- What defines a good CNC parts supplier in 2025?

- What types of industries need CNC precision parts?

- How does CNC technology evolve in 2025?

- Top 10 CNC Parts Manufacturers in 2025

- FAQs

- Conclusion

What defines a good CNC parts supplier in 2025?

Many buyers struggle with inconsistent tolerances and long lead times from average suppliers.

In 2025, the best CNC suppliers combine technical precision, certified quality systems, responsive support, and competitive pricing across global markets.

Criteria that separate reliable CNC manufacturers

| Feature | What to Look For | Why It Matters |

|---|---|---|

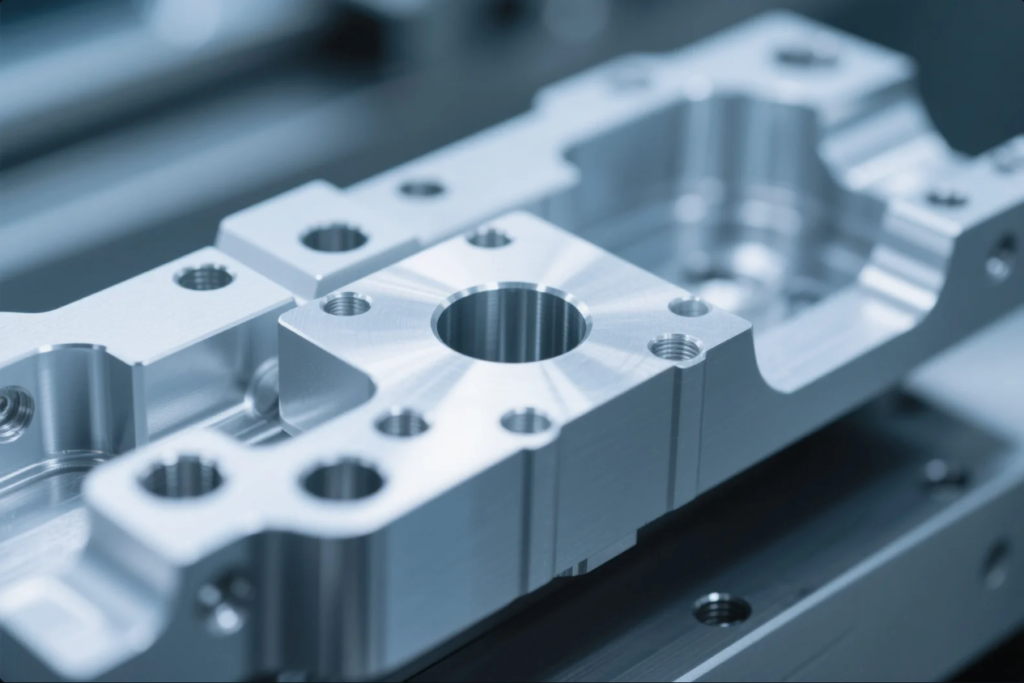

| Precision Tolerance | ±0.01mm or better | High-performance applications |

| Material Expertise | Metals, plastics, alloys | Versatile production capacity |

| Quality Certifications | ISO 9001, ISO 14001 | Assures process control |

| Customization Flexibility | Prototype to large batch | Fits any project scale |

| Global Logistics | Fast shipping, export-ready | On-time delivery worldwide |

Shandong Prime International Trade Co., Ltd. meets all these benchmarks. With 10 automated CNC production lines, over 20 years of export experience, and fast-response customer service, Prime is a leading CNC parts precision machining supplier.

What types of industries need CNC precision parts?

From robotics to medical devices, CNC machining is foundational to modern manufacturing.

Industries that rely heavily on CNC parts include aerospace, automotive, industrial automation, energy, consumer electronics, and medical.

Examples of precision parts by sector

| Industry | Common CNC Parts | Quality Requirement |

|---|---|---|

| Aerospace | Turbine blades, brackets | Lightweight, ultra-precise |

| Automotive | Engine mounts, drive shafts | High volume, consistent QC |

| Electronics | Heat sinks, housings | Tight tolerance, clean finishes |

| Medical | Surgical tools, housings | Sterile-ready, biocompatible |

| Robotics | Gearboxes, arms | High strength, low backlash |

Prime has delivered bulk CNC components for smart factory systems, electric vehicle chassis brackets, and even custom connectors for marine equipment. Our clients include European distributors, North American OEMs, and Middle Eastern automation integrators.

How does CNC technology evolve in 2025?

CNC tech is smarter and faster. Buyers need suppliers who upgrade with the times.

The top trends in 2025 include 5-axis machining, AI-assisted programming, hybrid additive-subtractive systems, and real-time production monitoring.

What your CNC supplier must adapt to

| Technology | Benefit to Buyer | Prime's Implementation |

|---|---|---|

| 5-Axis Machining | Reduces setup time, increases precision | Used on complex parts |

| CAD/CAM Integration | Shortens lead time | Accepts all file types |

| Automation | Improves efficiency | 24/7 unmanned production |

| AI Process Optimization | Reduces error and scrap | In-house smart scheduling |

| Smart QC Systems | Real-time inspection | Inline dimensional control |

With global competition tightening, only CNC suppliers who evolve technically — like Prime — can ensure long-term partnerships.

Top 10 CNC Parts Manufacturers in 2025

Here’s a carefully vetted list of CNC parts manufacturers that excel in 2025 based on production capability, certification, global reach, and customer feedback.

-

Shandong Prime International Trade Co., Ltd.

- Founded: 1993, China

- Strengths: ISO-certified, 10 production lines, B2B wholesale only

- Exports: North America, Europe, Middle East, Australia

- Clients: Siemens suppliers, auto part traders, equipment manufacturers

- Services: One-stop CNC, stamping, casting, welding

- Contact: [email protected]

-

- Country: USA

- Focus: On-demand CNC and rapid prototyping

- Capability: Automated quoting, online DFM tools

- Certifications: ISO 9001

-

- Country: USA/Asia

- Strength: Cloud manufacturing platform

- Support: Instant RFQs, real-time production visibility

- Certifications: ISO 13485

-

- Country: USA, global network

- Specialty: Marketplace model for CNC, 3D, sheet metal

- Unique: AI-based pricing and partner vetting

-

- HQ: Netherlands

- Platform: Instant manufacturing across global CNC vendors

- Certifications: ISO 9001, ITAR

-

- Location: China

- Focus: Custom CNC, injection molding

- Benefit: Competitive Chinese pricing, 24/7 support

-

- HQ: UK

- Platform: Fast access to certified CNC partners

- Industry Fit: Medical, automotive, aerospace

-

- Country: China

- Capability: Complex CNC, 3D scanning, reverse engineering

- Service: High accuracy, strong export logistics

-

- HQ: Estonia

- Strength: Smart matching of engineering drawings to CNC partners

- Industries: Industrial equipment, structural components

-

- Country: China

- Specialty: Small-batch CNC, transparent pricing

- Advantage: Cleanroom-ready, prototype-to-production bridge

These companies are trusted by thousands of B2B clients across industries — from Tier 1 automotive to niche robotics startups.

FAQs

Q1: What’s the best way to verify a CNC supplier’s quality?

A1: Ask for ISO certificates, sample parts, factory audits, and tolerance charts.

Q2: How fast can I get parts from Prime?

A2: Lead times vary by complexity but most CNC parts ship within 7–12 days worldwide.

Q3: Can Prime customize surface finishes?

A3: Yes. Options include anodizing, powder coating, sandblasting, and polishing.

Q4: Does Prime accept small orders?

A4: Yes. Prime supports low MOQ, ideal for pilots and R\&D procurement.

Q5: How do I start a quote request?

A5: Visit primecustomparts.com or email [email protected].

Conclusion

Precision, speed, and stability — these are the foundations of modern CNC manufacturing. In 2025, choosing a supplier who matches your technical demands and delivery expectations is critical. If you're looking for a trusted CNC partner, Shandong Prime International Trade Co., Ltd. offers ISO-certified service, one-on-one engineering support, and fast export worldwide.