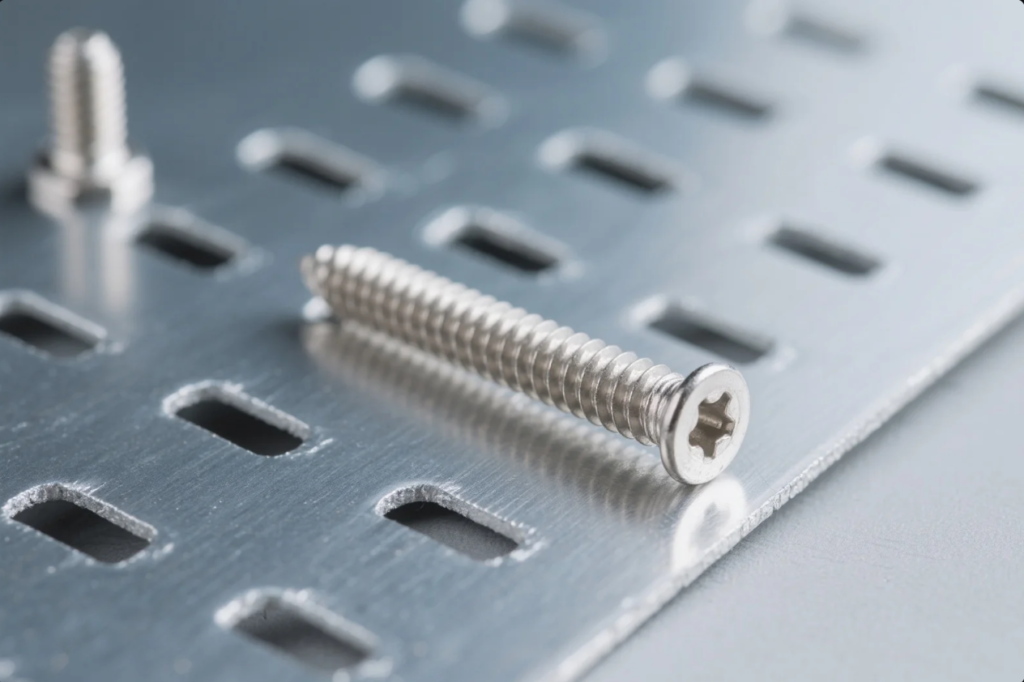

Will Galvanized Screws React with Aluminum?

Mixing galvanized screws with aluminum can cause galvanic corrosion, compromising structural integrity.

In 2025, understanding the compatibility between galvanized screws and aluminum is crucial to prevent galvanic corrosion. This article explores the interactions, suitable alternatives, and best practices for fastening aluminum components.

Incorrect fastener choices can lead to premature failures. Let's delve into the specifics to ensure durability and safety.

Table of Contents

- Can You Use Aluminum and Galvanized Together?

- What Screws Are Compatible with Aluminum?

- What Metals Should Not Be Used on Aluminum?

- Will Steel Screws React with Aluminum?

- Best Practices for Preventing Galvanic Corrosion

- FAQs

- Conclusion

Can You Use Aluminum and Galvanized Together?

Using galvanized screws with aluminum can lead to galvanic corrosion, especially in moist environments.

Galvanized screws, coated with zinc, can cause aluminum to corrode when both metals are in contact and exposed to an electrolyte, such as water.

Understanding Galvanic Corrosion

| Environment | Corrosion Risk |

|---|---|

| Dry Indoor | Low |

| Humid Indoor | Moderate |

| Outdoor | High |

| Marine | Very High |

To mitigate risks:

- Use insulating materials like nylon washers.

- Apply protective coatings.

- Consider alternative fasteners compatible with aluminum.

What Screws Are Compatible with Aluminum?

Selecting the right screws ensures longevity and structural integrity when fastening aluminum components.

Compatible screws for aluminum include stainless steel, anodized aluminum, and coated brass screws.

Recommended Fasteners

| Screw Material | Compatibility | Notes |

|---|---|---|

| Stainless Steel | Excellent | Resistant to corrosion |

| Anodized Aluminum | Excellent | Prevents galvanic reactions |

| Coated Brass | Good | Suitable for indoor applications |

Avoid using plain steel or galvanized screws without proper insulation.

What Metals Should Not Be Used on Aluminum?

Certain metals can accelerate corrosion when in contact with aluminum.

Metals to avoid include plain steel, copper, and galvanized steel, especially in the presence of moisture.

Metals to Avoid

| Metal | Reason |

|---|---|

| Plain Steel | High corrosion potential |

| Copper | Causes rapid corrosion |

| Galvanized Steel | Risk of galvanic corrosion |

When dissimilar metals must be used:

- Isolate them with non-conductive materials.

- Apply appropriate coatings.

- Ensure minimal exposure to electrolytes.

Will Steel Screws React with Aluminum?

Steel screws can cause aluminum to corrode due to galvanic reactions.

When steel screws are used with aluminum, especially in moist conditions, galvanic corrosion can occur, leading to structural degradation.

Prevention Strategies

- Use compatible fasteners like stainless steel.

- Apply anti-corrosion coatings.

- Implement insulating barriers between dissimilar metals.

Best Practices for Preventing Galvanic Corrosion

To ensure the longevity of aluminum assemblies:

- Material Selection: Choose metals close in the galvanic series.

- Insulation: Use non-conductive materials between dissimilar metals.

- Protective Coatings: Apply appropriate coatings to prevent direct contact.

- Environmental Control: Minimize exposure to moisture and corrosive environments.

Implementing these practices can significantly reduce the risk of galvanic corrosion.

FAQs

Q1: Can I use galvanized screws with aluminum for outdoor projects?

A1: It's not recommended due to the high risk of galvanic corrosion in moist environments.

Q2: What is the best screw material for aluminum in marine environments?

A2: Stainless steel, particularly 316 grade, is ideal due to its corrosion resistance.

Q3: How can I prevent galvanic corrosion when using dissimilar metals?

A3: Use insulating materials, apply protective coatings, and minimize exposure to electrolytes.

Q4: Are there coatings that can make galvanized screws safe for use with aluminum?

A4: While coatings can reduce risks, it's safer to use inherently compatible materials.

Q5: Does anodizing aluminum prevent galvanic corrosion?

A5: Anodizing provides a protective layer, reducing the risk of corrosion when in contact with other metals.

Conclusion

Galvanized screws can react with aluminum, leading to galvanic corrosion. To ensure structural integrity and longevity, use compatible fasteners like stainless steel or anodized aluminum. For expert advice and quality fasteners, visit Prime or contact us at [email protected].