Top 10 Fasteners of Metal Parts Manufacturers in 2025: Capabilities, Expertise, and Selection Criteria?

Frustrated with inconsistent fastener quality and delayed delivery? You’re not alone. In 2025, choosing the right metal fastener manufacturer is critical to keeping your production line moving.

This guide compares the top 10 fasteners of metal parts manufacturers of 2025. It covers their capabilities, specializations, certifications, and how to choose the right supplier.

Scroll on to discover industry leaders in quality fasteners—and how to work with the one that suits your project best.

Table of Contents

- What industry uses the most fasteners?

- What are the most common metal fasteners used in construction?

- What are the kinds of metal fasteners?

- What are fastener companies?

- Top 10 Fastener Manufacturers in 2025

- Selection Criteria for Fastener Suppliers

- FAQs

- Conclusion

What industry uses the most fasteners?

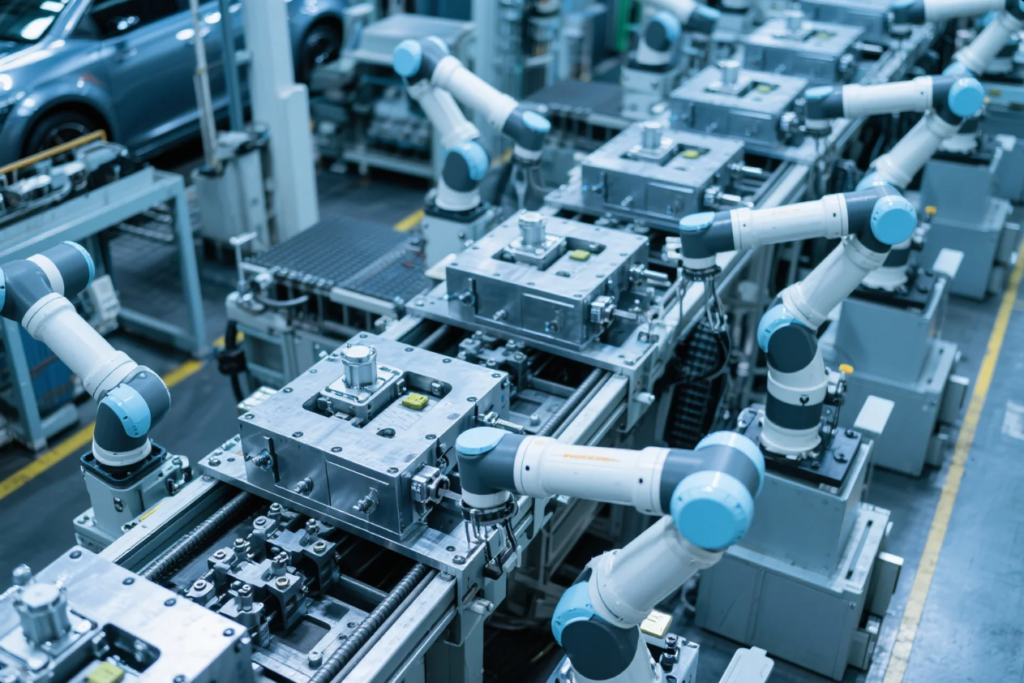

The automotive industry remains the largest user of fasteners in 2025, followed closely by aerospace, construction, and electronics.

Every car contains 3,000–5,000 fasteners. From body assembly to battery casings, OEMs demand precision, consistency, and certified quality.

Other high-volume industries include:

- Aerospace: High-strength, lightweight, traceable fasteners

- Construction: Corrosion-resistant structural bolts, anchors

- Electronics: Micro screws for smartphones, servers, and circuit boards

- Medical Devices: Biocompatible screws for implants and surgical tools

What are the most common metal fasteners used in construction?

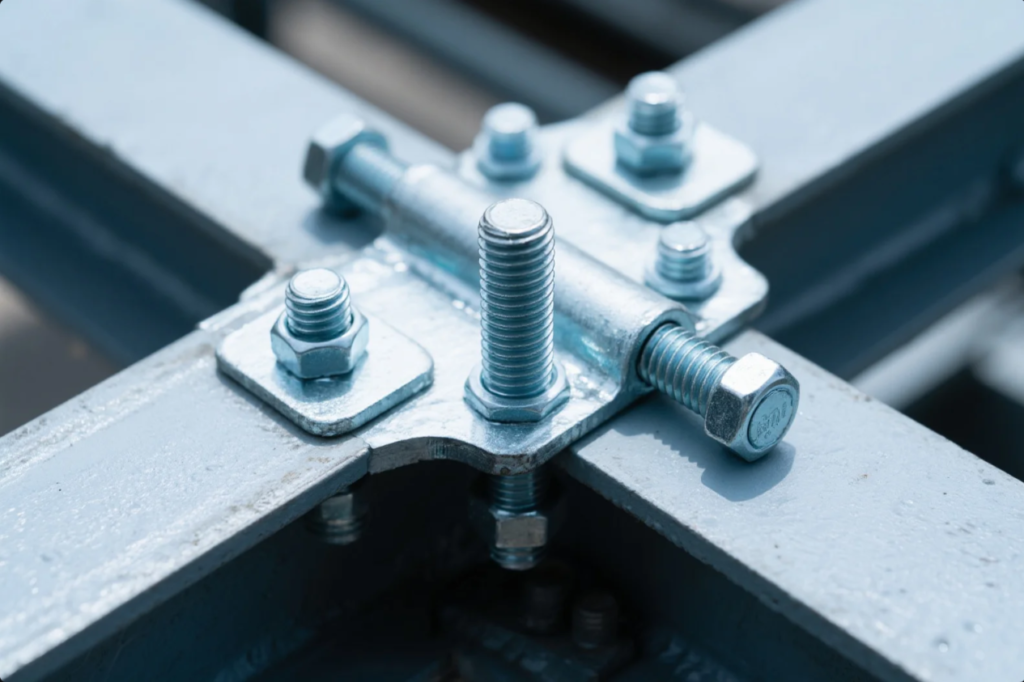

Construction depends heavily on heavy-duty, corrosion-resistant fasteners:

Key types include:

- Anchor bolts: Secure steel frames to concrete

- Hex bolts & nuts: Common in framing and steel joining

- Lag screws & carriage bolts: Wood-to-metal structural assemblies

- Concrete/masonry screws: Used without anchors

- Threaded rods & washers: Provide tension and load distribution

Hot-dip galvanized coatings are standard for outdoor use. Increasingly, stainless steel fasteners are specified for high-end and exposed architecture.

What are the kinds of metal fasteners?

Fasteners vary in design and application. Here’s a breakdown of major types:

| Fastener Type | Common Use Case |

|---|---|

| Bolts | Structural steel and mechanical joints |

| Screws | Wood, metal, or plastic joints |

| Nuts | Used with bolts for secure fastening |

| Washers | Load distribution and anti-loosening |

| Rivets | Permanent joints in aerospace, marine |

| Studs | Automotive engines, heavy machinery |

| Anchors | Concrete and masonry fastening |

Advanced fasteners in 2025 include smart bolts, self-locking nuts, and pre-tensioned structural fasteners.

What are fastener companies?

Fastener companies manufacture components like screws, nuts, bolts, washers, anchors, and pins. In 2025, they also provide:

- Custom fastener engineering

- ISO and ASTM testing services

- Smart fasteners with embedded sensors

- Surface treatments (zinc plating, black oxide, etc.)

- Global logistics and packaging services

Top 10 Fastener Manufacturers in 2025

1. Prime Custom Parts (China)

Overview:

Founded in 1993, Prime Custom Parts is a trusted B2B supplier specializing in fasteners, CNC machining, and metal stamping.

Production Advantages:

- 10 in-house production lines ensure tight control on quality and delivery

- Supports custom specifications and fast lead times

- ISO-certified processes, global export to North America, Europe, and the Middle East

- One-stop service from design to packaging

2. Bossard Group (Switzerland)

Overview:

A global leader in fastening technology with a strong emphasis on engineering and logistics integration.

Production Advantages:

- Advanced smart factory logistics systems

- Expert engineering support with application-specific solutions

- Quality control with traceable documentation

- Strong inventory and VMI services for OEMs

3. Hilti Group (Liechtenstein)

Overview:

A pioneer in fastening systems for construction, Hilti specializes in innovation for anchoring and seismic-rated applications.

Production Advantages:

- Proprietary fastening systems tailored for high-load building projects

- On-site testing and consulting services

- Compliant with strict international codes and seismic standards

- Strong R\&D for long-lasting construction fasteners

4. Stanley Black & Decker (USA)

Overview:

A century-old name known for industrial tools and fastening systems across sectors including automotive and aerospace.

Production Advantages:

- Vertically integrated operations

- Specialized high-torque, impact-rated fasteners

- U.S.-based R\&D and extensive global distribution

- Brands include DEWALT®, Powers®, and Mac Tools®

5. Illinois Tool Works (ITW) (USA)

Overview:

ITW is a diversified manufacturer with a strong segment focused on engineered fasteners for automotive, aerospace, and electronics.

Production Advantages:

- Custom design for OEM assemblies

- Patented fastener technology for panel joining

- Global manufacturing footprint for just-in-time delivery

- Robust product validation systems

6. Nippon Industrial Fasteners (NIFCO) (Japan)

Overview:

World-renowned for high-quality plastic fasteners for automotive interiors, electronics, and consumer products.

Production Advantages:

- In-house mold design and injection systems

- High-speed production with tight tolerances

- Extensive product catalog of clips, cable ties, grommets

- Solutions tailored for light-weighting and aesthetics

7. TR Fastenings (UK)

Overview:

TR provides fasteners and components for electronics, automotive, and industrial sectors across more than 30 countries.

Production Advantages:

- In-house testing, plating, and traceability systems

- Strong Asia-based manufacturing with global warehousing

- ISO/TS certification for tier 1 supply

- Online catalog with 3D CAD downloads

8. Penn Engineering (PEM) (USA)

Overview:

Penn Engineering is a leader in self-clinching and press-fit fasteners for sheet metal and electronics.

Production Advantages:

- Specialized in captive fasteners for small form factors

- Ideal for PCB mounting, server racks, and telecom devices

- Cleanroom production lines for medical and defense

- Detailed technical documentation and support

9. Bulten AB (Sweden)

Overview:

A leading supplier of fasteners to global automotive OEMs with full-service development and logistics.

Production Advantages:

- Strong focus on sustainability and lightweight design

- Supplier to brands like Volvo, BMW, and Mercedes-Benz

- Operates under IATF and ISO/TS quality systems

- Localized production across Europe and Asia

10. Fastenal (USA)

Overview:

North America’s leading industrial fastener distributor and manufacturer with over 3,000 locations.

Production Advantages:

- Extensive domestic inventory with same-day delivery

- Custom fastener manufacturing with RFQ system

- Vending machines and MRO solutions

- Local support + global sourcing options

Selection Criteria for Fastener Suppliers

Before placing an order, ask yourself:

1. What certifications do they have?

Look for ISO 9001, IATF 16949 (auto), or AS9100 (aero) based on your industry.

2. What’s their MOQ and lead time?

Ideal suppliers offer scalable production with fast delivery.

3. Do they offer custom design support?

Engineering assistance can reduce cost and increase reliability.

4. Do they handle packaging and labeling?

Essential for export orders, retail-ready packaging, or barcode systems.

5. Can they provide test reports or PPAP?

Traceability and quality assurance are key to compliance.

FAQs

Q: How are fasteners tested for strength?

A: Using tensile, shear, and fatigue testing per ASTM/ISO specs.

Q: What coating is best for corrosion resistance?

A: Zinc-nickel plating or hot-dip galvanizing for outdoor exposure.

Q: Can I get custom fasteners in low volume?

A: Yes. Companies like Prime Custom Parts offer small-batch prototyping.

Q: Do fastener companies provide CAD files or 3D models?

A: Leading suppliers offer downloadable CAD files and design support.

Q: Are smart fasteners real in 2025?

A: Yes. Used in aerospace, infrastructure, and machinery to monitor tension or detect vibration.

Conclusion

Top 10 Fasteners of metal Parts Manufacturers in 2025. Choosing the right fastener manufacturer in 2025 is not just about price—it’s about precision, lead time, and reliability. The manufacturers listed here provide top-tier products with the certifications, capabilities, and service modern supply chains demand.

📩 Need ISO-certified fasteners fast?

Contact Prime Custom Parts at [email protected] for free consultation, quote, or engineering assistance.