Die Casting vs Investment Casting: Which Metal Process Fits Your Needs?

Choosing the wrong casting method can lead to production delays and increased costs.

Die casting and investment casting serve different needs. Understanding their differences is crucial for selecting the right process in 2025.

Selecting the appropriate casting method ensures optimal product quality and cost-efficiency. Let's delve into the specifics to help you make an informed decision.

Table of Contents

- What is the difference between die casting and investment casting?

- What is the most common metal casting process?

- What metals can be investment casted?

- What is the difference between investing and casting?

- FAQs

- Conclusion

What is the difference between die casting and investment casting?

Understanding the fundamental differences between die casting and investment casting is essential for selecting the appropriate manufacturing process.

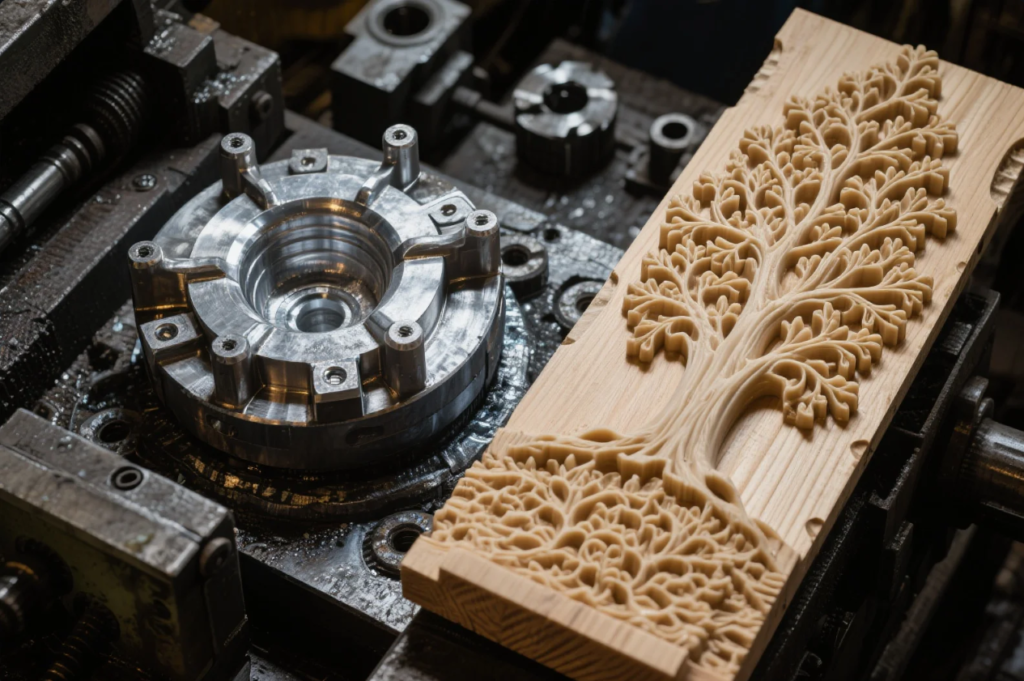

Die casting involves injecting molten metal under high pressure into a steel mold, while investment casting involves pouring molten metal into a ceramic mold formed around a wax pattern.

Die casting is typically used for high-volume production of non-ferrous metal parts with excellent surface finish and dimensional accuracy. Investment casting, on the other hand, is suitable for producing complex shapes with high precision, accommodating a wide range of metals.

🆚 Key Differences Between Die Casting and Investment Casting

| Feature | Die Casting | Investment Casting |

|---|---|---|

| Mold Type | Permanent steel molds | Disposable ceramic molds |

| Production Volume | High-volume | Low to medium-volume |

| Material Suitability | Non-ferrous metals (e.g., aluminum, zinc) | Ferrous and non-ferrous metals |

| Surface Finish | Excellent | Very good |

| Dimensional Accuracy | High | Very high |

| Tooling Cost | High upfront cost | Moderate |

| Lead Time | Shorter | Longer due to mold preparation |

For more detailed comparisons, refer to MetalTek's blog on casting processes.

What is the most common metal casting process?

Selecting the most common casting process depends on factors like production volume, material, and part complexity.

Sand casting is the most widely used metal casting process due to its versatility and cost-effectiveness.

Sand casting involves creating a mold from a sand mixture and pouring molten metal into the cavity. It's suitable for a wide range of metals and is often used for large components. However, it may not achieve the same level of precision and surface finish as die or investment casting.

For an overview of various casting methods, visit Xometry's guide on casting types.

What metals can be investment casted?

Investment casting offers flexibility in material selection, accommodating both ferrous and non-ferrous metals.

Metals commonly used in investment casting include stainless steel, carbon steel, aluminum alloys, brass, bronze, and superalloys.

This process is ideal for producing components that require intricate details and high dimensional accuracy. It's widely used in industries like aerospace, automotive, and medical devices.

For more information on suitable materials, check out CFS Foundry's guide on investment casting metals.

What is the difference between investing and casting?

Understanding the terminology is crucial for grasping the investment casting process.

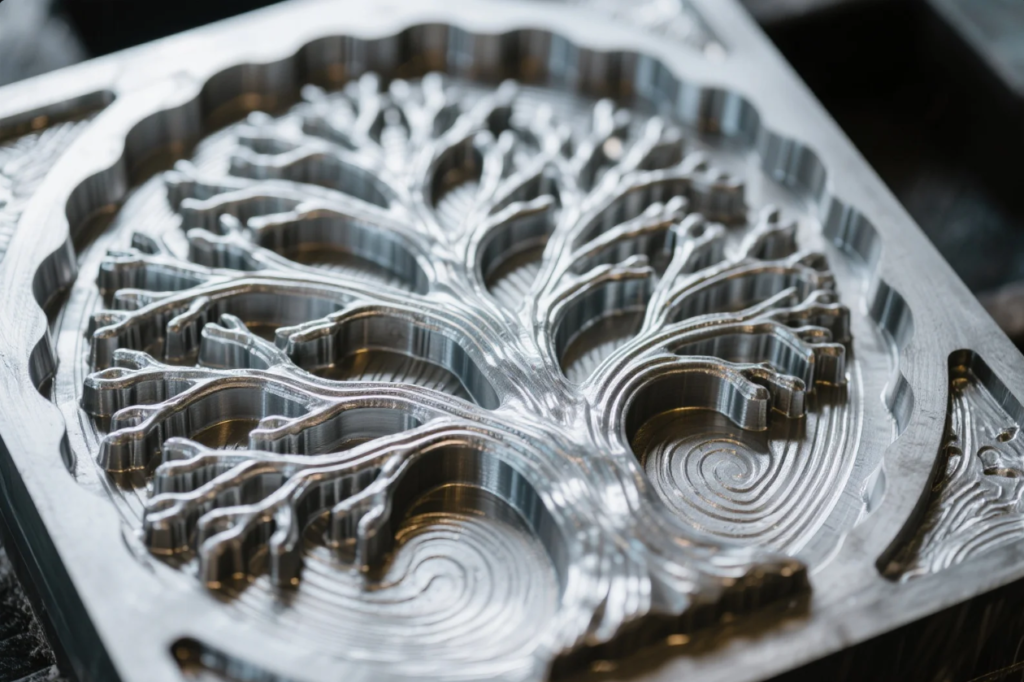

"Investing" refers to creating a ceramic mold around a wax pattern, while "casting" involves pouring molten metal into this mold to form the final part.

The investment casting process includes:

- Creating a wax pattern of the desired part.

- "Investing" the pattern by coating it with a ceramic slurry to form a mold.

- Removing the wax through heating, leaving a cavity.

- Pouring molten metal into the cavity.

- Allowing the metal to cool and solidify.

- Breaking the ceramic mold to retrieve the cast part.

For a comprehensive explanation, refer to Wikipedia's article on investment casting.

FAQs

Q1: Which process is more cost-effective for high-volume production?

A1: Die casting is generally more cost-effective for high-volume production due to its faster cycle times and reusable molds.

Q2: Can investment casting produce parts with complex geometries?

A2: Yes, investment casting excels at producing parts with intricate designs and tight tolerances.

Q3: What are the size limitations for die casting?

A3: Die casting is typically limited to smaller to medium-sized parts due to equipment constraints.

Q4: Is post-processing required for investment cast parts?

A4: Investment cast parts often require minimal post-processing, as they achieve near-net shape.

Q5: Which process offers better surface finish?

A5: Both processes offer excellent surface finishes, but die casting generally provides a smoother finish without additional processing.

Conclusion

Selecting the appropriate casting method depends on factors like production volume, material, part complexity, and cost considerations.

For expert guidance on choosing the right casting process for your project, contact Prime today. We offer free consultations, accurate quotes, and tailored solutions to meet your manufacturing needs.

Visit our website: https://primecustomparts.com/

Email us at: [email protected]