Top 10 CNC Metal Parts Suppliers for Precision Engineering Projects

Sourcing reliable CNC metal parts suppliers is critical for precision engineering projects in 2025—yet many companies still struggle with inconsistent tolerances and long lead times.

This guide ranks the top 10 CNC parts suppliers for precision engineering and explains what makes a great partner in CNC manufacturing today.

If you’re looking for ISO-certified production, micro-precision capability, and international logistics—this list gives you clarity without wasting time.

Table of Contents

- What are the 7 major parts of a CNC machine?

- What is CNC in precision engineering?

- Who is the best manufacturer of CNC machines?

- What is the biggest CNC company in the world?

- Top 10 CNC Metal Parts Suppliers in 2025

- FAQs: Choosing the Right CNC Parts Supplier

- Conclusion

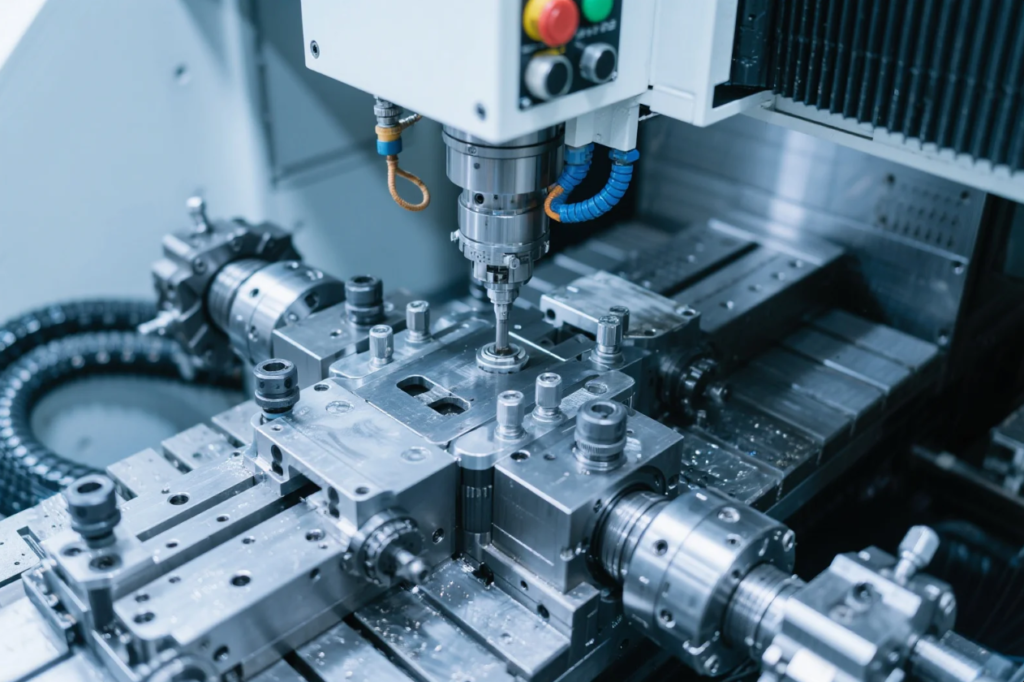

What are the 7 major parts of a CNC machine?

Understanding the anatomy of a CNC machine helps you know what affects accuracy and stability.

The 7 major parts of a CNC machine are:

- Control Panel – Sends instructions from G-code to the machine.

- Spindle – Rotates the cutting tool at high speed.

- Axes (X/Y/Z) – Control motion and direction.

- Bed/Table – Holds and supports the workpiece.

- Chuck or Collet – Secures the part or tooling.

- Coolant System – Prevents overheating during high-speed cutting.

- Drive Motor & Servo System – Provides motion accuracy and repeatability.

If any part underperforms, the final product’s precision suffers. That’s why investing in both top-grade machines and trustworthy CNC suppliers matters.

What is CNC in precision engineering?

CNC (Computer Numerical Control) in precision engineering refers to using programmed code to cut, mill, or drill metal into exact shapes.

Precision engineering relies on CNC for these reasons:

- Repeatability – Produces parts with tolerance within ±0.01 mm.

- Complex Geometry – Enables 3D features and intricate surface paths.

- Reduced Errors – Removes manual deviation from the equation.

- Speed – Cuts lead time in half compared to manual machining.

Industries like aerospace, automotive, and robotics depend on CNC for parts that meet tight specifications and certification standards.

Who is the best manufacturer of CNC machines?

If you’re asking who makes the best CNC machines in the world, three names stand out:

- DMG Mori (Germany + Japan) – Known for high-precision 5-axis CNC and automation solutions.

- Mazak (Japan) – Offers user-friendly interface and strong service networks.

- Haas Automation (USA) – Most popular in North America, great for training and low-maintenance machines.

The brand you choose will influence your machining strategy, tooling options, and long-term efficiency.

What is the biggest CNC company in the world?

Based on 2025 global revenue, Fanuc Corporation is considered the largest CNC systems supplier worldwide.

- Based in Japan

- Supplies CNC controllers to over 50% of the world’s machines

- Dominates automation in robotics and industrial motion control

While Fanuc focuses more on CNC software and drives, it influences every other major brand and factory setup.

Top 10 CNC Metal Parts Suppliers in 2025

This list highlights the most reliable CNC metal parts suppliers for global buyers based on quality, scale, and export capability:

| Rank | Supplier | Country | Capabilities | Certifications |

|---|---|---|---|---|

| 1 | Shandong Prime International Trade | China | CNC machining, prototyping, small batches | ISO 9001, Custom Logo |

| 2 | Protolabs | USA | Rapid prototyping & online quoting | ISO 13485, AS9100 |

| 3 | Xometry | USA | Global CNC supplier marketplace | ISO 9001 |

| 4 | Fictiv | USA/China | CNC machining + digital manufacturing | ISO 9001 |

| 5 | 3ERP | China | Low-volume CNC + pressure die casting | ISO 9001 |

| 6 | RapidDirect | China | Instant quoting, wide metal range | ISO 9001, IATF 16949 |

| 7 | HLH Prototypes | China | CNC + vacuum casting | ISO 9001 |

| 8 | WayKen | China | CNC milling, turning, surface finish | ISO 9001 |

| 9 | Star Rapid | China | CNC prototyping, aluminum machining | ISO 9001, AS9100 |

| 10 | Geomiq | UK | Online CNC services | ISO 9001 |

FAQs: Choosing the Right CNC Parts Supplier

Q1: What makes a CNC supplier reliable for precision projects?

A: Look for tight tolerances, documented quality control, fast quoting, and flexible batch sizes.

Q2: Can I get small quantity CNC parts from Prime?

A: Yes. Prime supports prototypes, MOQ-free options, and urgent samples.

Q3: Do CNC suppliers support custom logo engraving?

A: Absolutely. Prime and most top-tier suppliers offer logo laser marking, part ID coding, and packaging customization.

Q4: What tolerance can CNC shops achieve today?

A: Standard tolerance is ±0.05 mm, while precision tolerance is ±0.01 mm depending on design.

Q5: Which materials are best for CNC precision?

A: Aluminum 6061, stainless steel 304, brass, and titanium are common picks. Prime can source per your spec.

Conclusion

For precision engineering success, choose CNC suppliers with ISO certification, flexible services, and proven global delivery.

📩 Need CNC parts that match your drawings exactly?

Contact Shandong Prime International Trade for high-precision prototypes, volume machining, and global fulfillment.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com