Top 5 Trends in Metal Parts Manufacturing in 2025 Driving Innovation

The metal parts industry is changing fast—those who fail to adapt to innovation risk losing competitive edge in quality, cost, and delivery.

This article explores the top 5 trends revolutionizing metal parts manufacturing in 2025, from AI to sustainability, and what it means for global B2B buyers.

If you're sourcing metal components, understanding these trends will help you make smarter supplier choices and stay ahead in your industry.

Table of Contents

- What is the future of metal fabrication?

- What is the next big thing in manufacturing?

- What are the emerging trends and technologies in the manufacturing sector?

- What are the HR trends in manufacturing?

- Top 5 Trends in Metal Parts Manufacturing in 2025

- FAQs: Adapting to the Future of Manufacturing

- Conclusion

What is the future of metal fabrication?

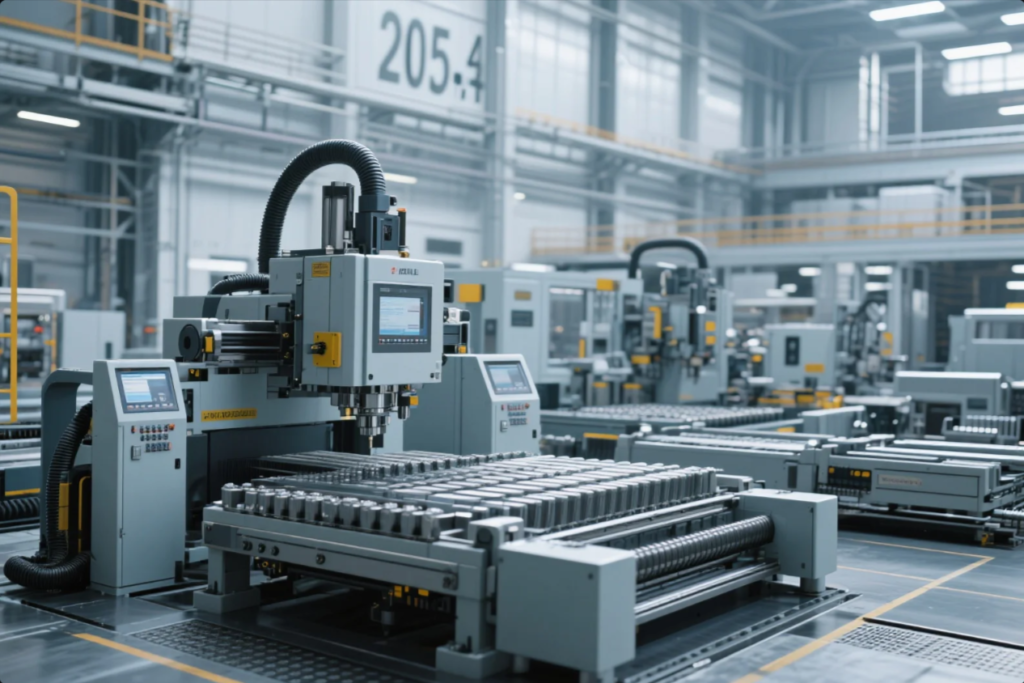

The future of metal fabrication revolves around automation, sustainability, and data-driven manufacturing.

Metalworking shops are shifting toward digital control and intelligent production systems.

At Shandong Prime, we already integrate real-time monitoring, paperless workflows, and digital CAD-to-CNC automation to improve delivery speed and part consistency.

By 2025, fully connected factories will dominate the landscape—eliminating inefficiencies and shortening the time from design to delivery.

What is the next big thing in manufacturing?

The next big thing is the full adoption of Industry 4.0—a system where machines, sensors, and software work together seamlessly.

Key innovations include:

- AI-powered quality inspection

- Predictive maintenance

- Machine-learning-based scheduling

- Automated tolerance verification

- Integrated ERP with factory floor feedback

Manufacturers using these technologies cut costs, prevent defects, and boost customer confidence.

What are the emerging trends and technologies in the manufacturing sector?

In 2025, the following manufacturing technologies are accelerating:

- AI + Machine Learning – Smart defect detection, adaptive machining

- Digital Twins – Virtual simulations of factory lines

- Collaborative Robots (Cobots) – Safer, smarter labor augmentation

- 3D Metal Printing – Used for tooling, jigs, and even final parts

- Cloud-based ERP and MES – Global transparency and speed

At Prime, we’re adopting these to offer better lead times, cost control, and traceability in every stamped or CNC part delivered.

What are the HR trends in manufacturing?

In parallel with tech, the workforce is evolving too.

The top HR trends in manufacturing include:

- Upskilling in data tools like CAD/CAM, CNC programming

- Remote monitoring roles for engineers and QC inspectors

- Cross-training between QA, production, and packaging

- Global hiring for digital talent

- Soft-skill emphasis: problem-solving, decision-making, digital literacy

At Prime, we invest heavily in internal training and process standardization, reducing turnover and enhancing part reliability for clients.

Top 5 Trends in Metal Parts Manufacturing in 2025

Here’s what’s actually changing on the factory floor—and what it means for your sourcing decisions:

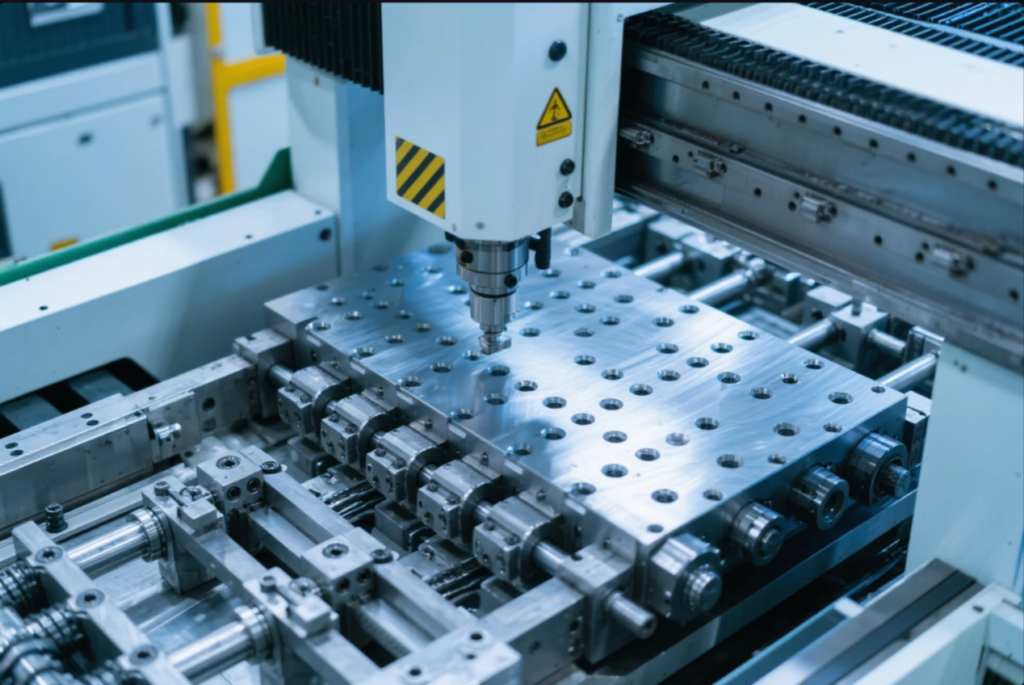

1. Smart CNC Machining

With CAM-AI software and sensor-driven feedback, machines optimize toolpaths in real time.

Prime’s CNC service applies this to ensure smooth surfaces and ±0.01 mm accuracy.

Buyer Benefit:

Faster delivery + reduced scrap = lower project cost

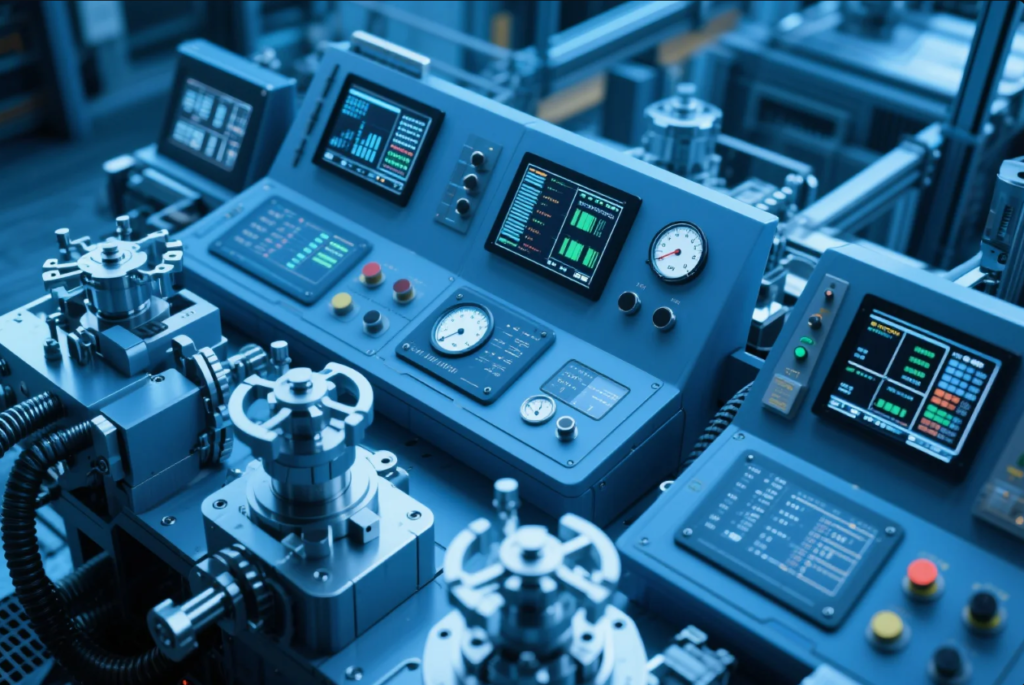

2. Predictive Quality Control

We integrate sensors into press lines and CNC centers. Vision systems analyze part edges, hole locations, and surface finish during production.

Technologies used:

- SPC dashboards

- IoT-connected gauges

- Automated inspection logs

Buyer Benefit:

ISO 9001-compliant reporting, fewer rejections, better batch control

3. Eco-Friendly Manufacturing

We now operate on energy-efficient stamping presses and closed-loop coolant recycling systems.

Sustainable practices at Prime include:

- Water-based cleaning agents

- VOC-free powder coating

- Recyclable export packaging

Buyer Benefit:

Compliance with your clients' ESG expectations

4. Rapid Customization with Modular Tooling

Need 500 pieces with a new logo next week? Prime can do it.

Our rapid die-change system and in-house CNC shop make it happen.

Speed Advantage:

Quote in 12 hrs.

Tooling in 48 hrs.

Shipping in 7–10 days.

Custom stamping services now meet both cost and agility expectations.

5. Global Fulfillment and Tracking

We’ve partnered with DHL, FedEx, and Alibaba Logistics to enhance our delivery promise.

- Real-time tracking links

- Auto-generated packing lists

- Dedicated account follow-up

Result:

96% on-time delivery in North America, Europe, and Middle East

FAQs: Adapting to the Future of Manufacturing

Q1: Can small businesses benefit from these trends?

A: Absolutely. Even low-volume orders now benefit from AI QC and real-time monitoring.

Q2: Are Prime’s parts certified?

A: Yes. All our products comply with ISO 9001, and we provide material test reports, COCs, and PPAP on request.

Q3: What if I want fast tooling for a new part?

A: We offer expedited tooling for prototypes—ready to ship in 3–5 days.

Q4: Can I request parts with custom barcodes and labels?

A: Yes. We offer packaging with QR, GS1 barcodes, customer logos, and carton-level tracking.

Q5: Does Prime offer free consultation?

A: Yes. Just email us your drawing and quantity—we’ll provide expert suggestions within 24 hours.

Conclusion

Manufacturers that embrace automation, sustainability, and global delivery models will lead the future of metal parts production.

📩 Ready to future-proof your sourcing?

Contact Shandong Prime International Trade for CNC, stamping, or casting services powered by innovation.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com