Top 7 Tooling Solutions for High-Precision Metal Component Production: Which Ones Matter Most?

Metal fabricators in 2025 must tackle tight tolerances, shorter lead times, and growing cost pressure. The right tooling solution can improve all three.

Precision tooling is the backbone of high-performance metal component production. From stamping to CNC to EDM, this article explores the top 7 tooling solutions helping global manufacturers deliver consistent quality and faster turnaround.

Find out which tools best fit your needs, and discover how certified suppliers like Prime offer tailored solutions that support your growth.

Table of Contents

- What are six types of tools used in metal fabrication?

- Is metal fabrication a good business?

- What do you need to be a metal fabricator?

- What is metal fabrication equipment?

- FAQs

- Contact Information

What are six types of tools used in metal fabrication?

Poor tooling results in missed specs and higher scrap rates. Choosing the right tool type avoids expensive rework.

Six key tooling categories dominate modern metal fabrication: cutting, forming, punching, joining, measuring, and finishing tools. Each serves a distinct role in transforming raw materials into precision components.

Tooling Types and Functions

| Tool Category | Example Tools | Primary Use |

|---|---|---|

| Cutting Tools | CNC mills, laser cutters | Material separation |

| Forming Tools | Press brakes, rollers | Shaping metal forms |

| Punching Tools | Turret punch, stamping dies | Creating holes and patterns |

| Joining Tools | Welders, rivet tools | Assembly and structure |

| Measuring Tools | Micrometers, CMMs | Tolerance control |

| Finishing Tools | Deburring tools, grinders | Surface preparation |

Looking for professional tooling reviews? See Fabricating & Metalworking’s Tooling Guide.

At Prime, our 10 production lines cover all six categories, including CNC precision machining and custom stamping solutions for export buyers.

Is metal fabrication a good business?

The answer depends on cost control, tooling strategy, and skilled operations.

Metal fabrication remains a strong business in 2025. Sectors like aerospace, EV, construction, and defense rely on tailored parts with consistent delivery and durable performance.

Why the Industry Still Grows

Global expansion is fueled by:

- Infrastructure and housing growth

- Electronics and green energy systems

- The shift to low-volume, high-mix manufacturing

However, the winners invest in:

- Skilled labor and training

- Smart, automated tooling setups

- Strong logistics and ISO-level documentation

For real-time data on industry growth, explore IBISWorld’s metal fabrication report.

Prime supports small-batch and large-volume production through integrated tooling systems, helping clients scale with confidence.

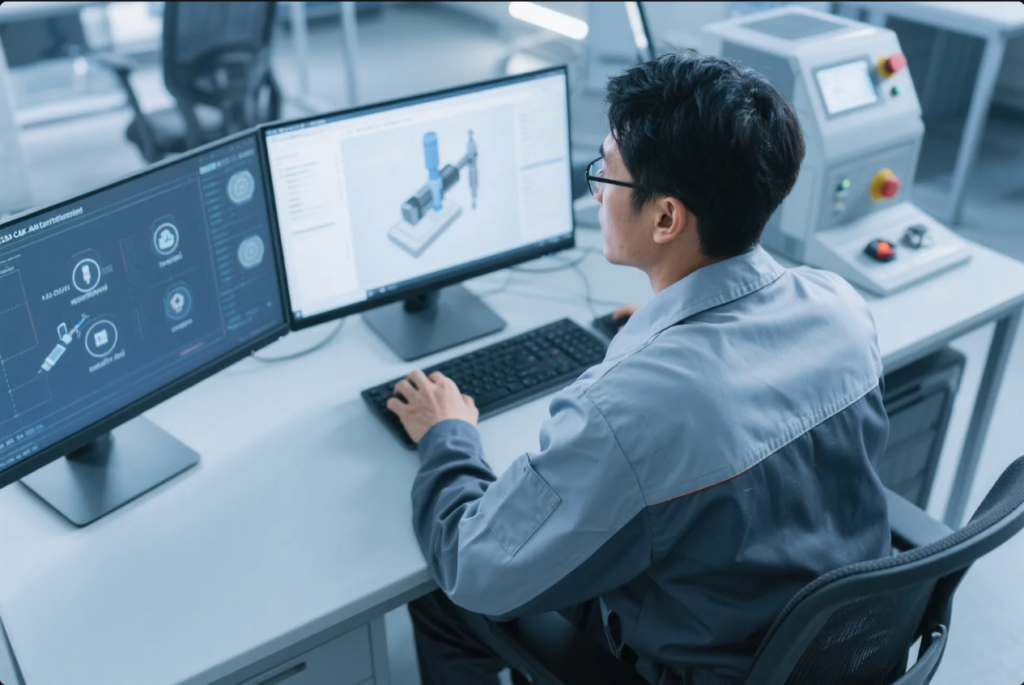

What do you need to be a metal fabricator?

Being a fabricator today is about precision, not just muscle.

Successful metal fabricators combine hands-on skill with digital tools, safety awareness, and an understanding of materials.

Skills and Tools for a Modern Fabricator

To excel, fabricators need:

- Knowledge of CNC and manual machine operation

- Proficiency with 2D/3D CAD software

- Understanding of metallurgy and surface specs

- Familiarity with ISO/CE/ROHS quality systems

- Willingness to adapt to new tech (e.g., AI, automation)

Want to break into the trade? See The Fabricator’s beginner guide.

Prime invests in training and digital workstations. Each team member is equipped with tooling checklists, digital calipers, and CAD terminals to support zero-defect production.

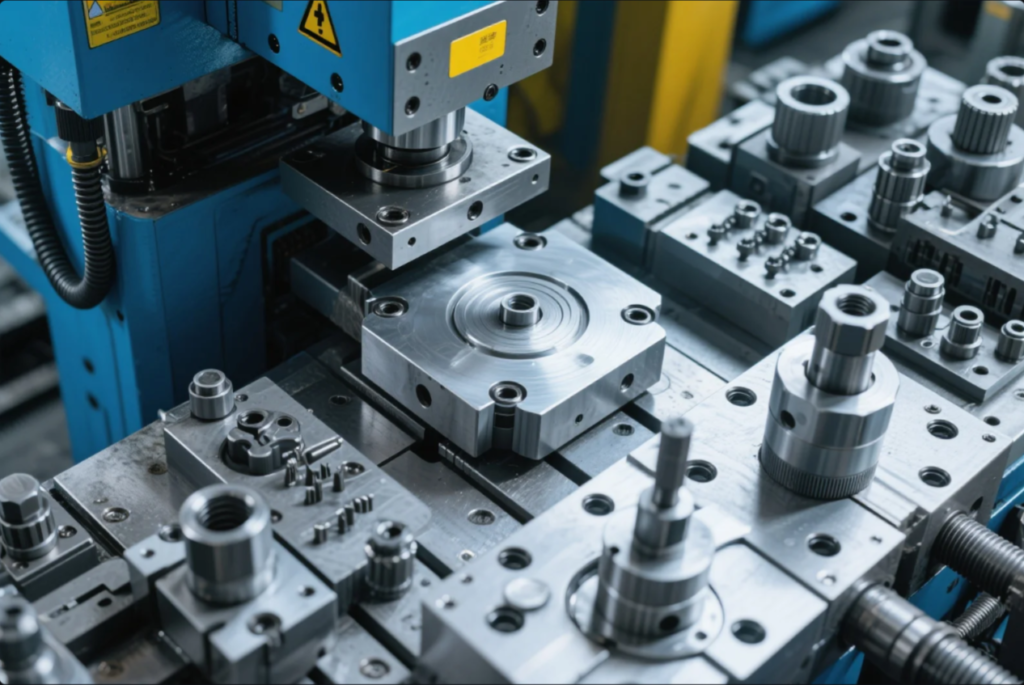

What is metal fabrication equipment?

Good equipment equals precision. Outdated machines can’t meet today’s quality requirements.

Modern fabrication equipment includes laser cutters, EDM machines, CNC tools, press brakes, robotic welders, and digital inspection tools. These systems ensure repeatable, high-accuracy output.

Core Equipment for Today’s Fabricators

| Equipment Type | Key Examples | Purpose |

|---|---|---|

| CNC Machining | 3-axis, 5-axis milling centers | Part shaping, hole drilling |

| Laser Cutting | Fiber/CO₂ laser | Clean, sharp material cutting |

| EDM | Wire EDM, sinker EDM | Mold making, micro-detailing |

| Forming | Hydraulic press brake | Sheet forming, angle bends |

| Welding | MIG, TIG, robotic welding | Part joining and structures |

| Inspection | CMMs, digital gauges | Dimensional assurance |

Want to browse modern equipment catalogs? Check TRUMPF's machine lineup.

At Prime, our ISO-certified casting and stamping division runs these machines 24/7 to meet tight export deadlines and complex specs.

FAQs

Q1: Which tool is most important in fabrication?

A1: CNC tools are the backbone of modern, versatile production.

Q2: Can tooling be customized for short runs?

A2: Yes, we regularly build short-run dies and flexible modular tools.

Q3: What’s the usual die lead time?

A3: Between 15–25 days depending on part complexity and finish requirements.

Q4: Do you offer automated post-processing?

A4: Yes, including polishing, deburring, and electroplating.

Q5: What’s Prime’s typical tolerance range?

A5: We deliver ±0.01 mm for CNC and ±0.05 mm for cast/molded parts.

Contact Information

Looking for fast, reliable tooling support?

- 🌐 Website: https://primecustomparts.com

- 📧 Email: [email protected]

We offer:

- Free DFM consultations

- 24-hour quotation turnaround

- Global freight support

- ISO-certified documentation packages

Ready to level up your metal fabrication capabilities in 2025?

Work with Prime, your global partner in precision tooling, custom metal stamping, and CNC machining—backed by 20+ years of manufacturing experience.