Top Mold Materials for Metal Part Production: Which One Should You Choose?

Choosing the right mold material is essential for precision, tool life, and part quality. Poor material choice leads to higher costs, defects, and production delays.

In this article, we compare the best mold materials for metal part production, from tool steels to ceramics. You’ll discover the pros, cons, and ideal applications of each—helping you choose the most cost-effective and durable option for your tooling needs.

Whether you’re producing 500,000 aluminum castings or 5,000 stainless steel parts via injection molding, selecting the right mold material is your first—and most important—decision.

Table of Contents

- What is the best material for mold?

- What material is most commonly used for molding?

- What are the two types of molds used in the metal casting process?

- What can I use as a mold for metal?

- FAQs

- Contact Information

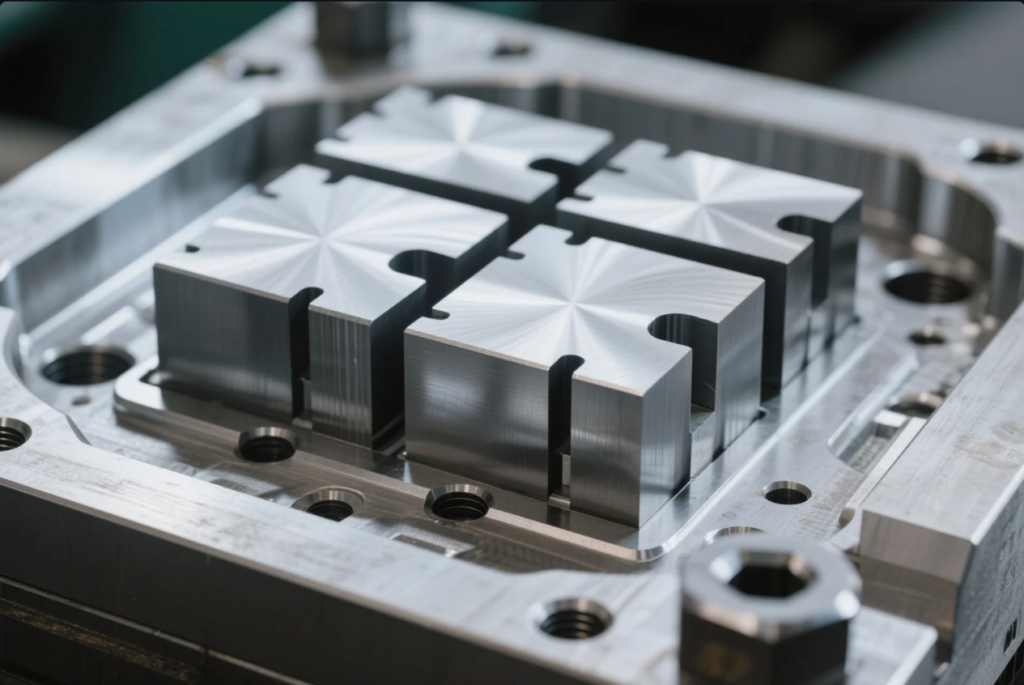

What is the best material for mold?

Tool steel is widely regarded as the best mold material for most metal part production due to its hardness, heat resistance, and wear durability.

Grades like H13, P20, and S7 are commonly used in molds for injection molding, die casting, and stamping due to their ability to withstand high pressure and thermal cycling.

Comparison of Common Mold Steels

| Material | Hardness (HRC) | Properties | Ideal Use Cases |

|---|---|---|---|

| P20 | 28–32 | Easy to machine, good toughness | Plastic molds, low-volume metal parts |

| H13 | 44–52 | Excellent thermal fatigue resistance | Die casting molds, high-temp alloys |

| S7 | 54–58 | High impact resistance | Forging dies, blanking tools |

| 420 SS | 48–55 | Polishable, corrosion resistant | Cosmetic plastic parts, cleanroom tools |

For detailed chemical composition and mechanical properties, visit Uddeholm’s official tool steel selector.

At Prime, we help clients choose between P20 for cost-efficiency or H13 when high-volume, high-heat performance is critical.

What material is most commonly used for molding?

The choice of mold material must align with what you’re molding—whether it’s plastic, metal powder, or even molten metal.

Thermoplastics such as ABS, PP, and PC are the most commonly molded materials for consumer and industrial plastic parts. For metal part molding, MIM (Metal Injection Molding) typically uses stainless steel, titanium, or alloy powders.

Material-Mold Compatibility Chart

| Molded Material | Common Mold Material | Notes |

|---|---|---|

| ABS/PP/PC | P20 / H13 steel | Low wear and shrinkage |

| Nylon with Glass | H13 / 420 SS | Needs abrasion resistance |

| 316L stainless | H13 / S7 | High-temp, high-pressure mold steel |

| Aluminum alloys | Graphite / steel | Die cast using permanent molds |

Want to compare material specs? Use Matmatch’s polymer database.

Prime engineers perform mold flow simulations to predict filling patterns, shrinkage, and optimal gate placement based on your part’s material.

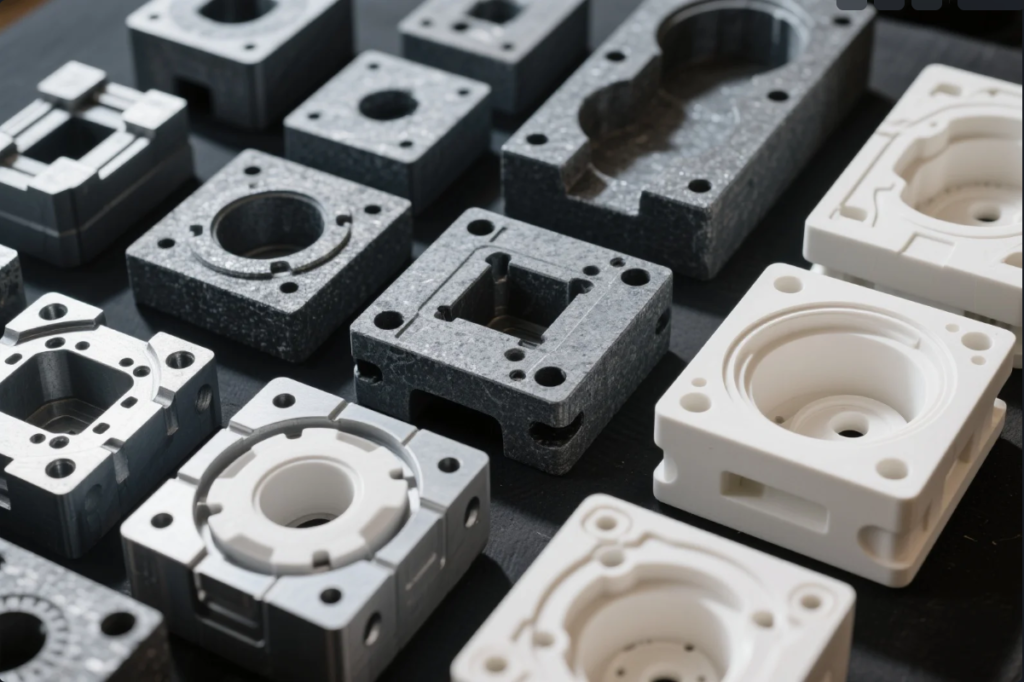

What are the two types of molds used in the metal casting process?

In metal casting, mold type affects cost, surface finish, and repeatability.

The two main types of molds are: (1) permanent molds, used repeatedly in die casting and gravity casting, and (2) expendable molds, like sand and ceramic, which are destroyed after use.

Side-by-Side Mold Type Comparison

| Mold Type | Reusability | Surface Finish | Cost per Unit | Typical Use |

|---|---|---|---|---|

| Permanent (Metal) | Reusable | Excellent | Low (high volumes) | Die-cast aluminum, zinc parts |

| Expendable (Sand) | One-time | Fair | Low (low volumes) | Cast iron, bronze, stainless |

Learn more from AFS’s casting process overview.

At Prime, we support both sand and die casting tooling, choosing based on geometry, batch size, and surface spec.

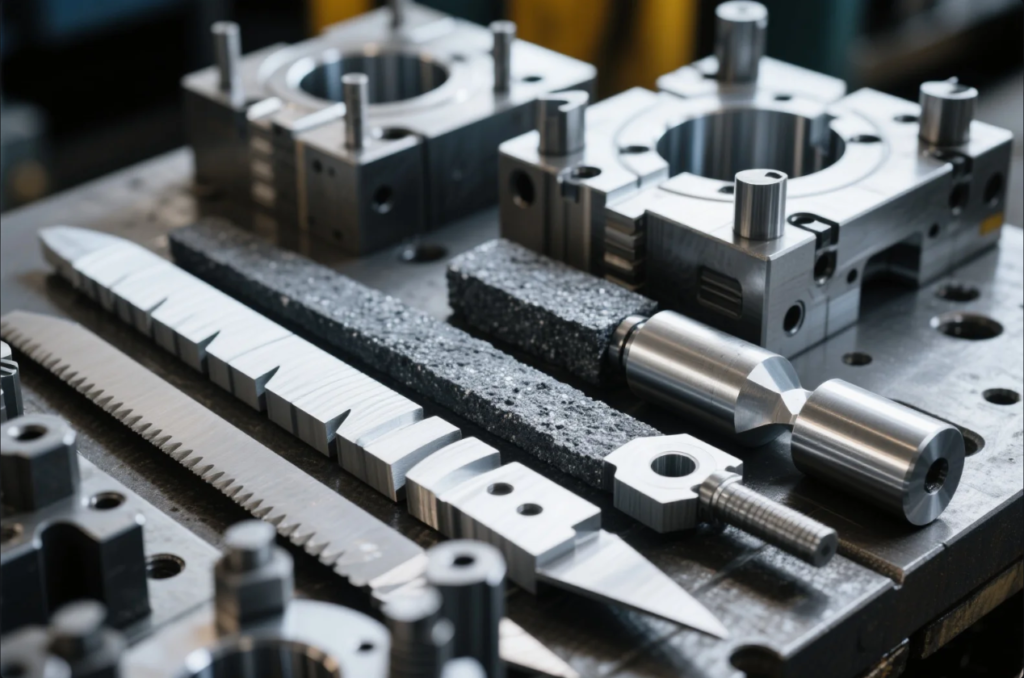

What can I use as a mold for metal?

Molds for molten metal must withstand intense heat and mechanical stress.

Popular mold materials for metal include tool steel (die casting), graphite (precious metals), sand (iron casting), and ceramics (investment casting).

Options for Metal Molding

| Material | Max Temp (°C) | Pros | Common Applications |

|---|---|---|---|

| Tool Steel | 1,100–1,300 | Durable, high cycle life | Die casting, injection molding |

| Graphite | \~3,000 | Chemically inert, easy to machine | Gold/silver/precious metal casting |

| Ceramic | 1,500–1,700 | Detail precision, smooth finish | Aerospace, investment casting |

| Sand | \~1,000 | Affordable, reusable sand cores | Large castings, steel parts |

| Silicone | \~300 | For low-temp alloys | Prototyping, jewelry casting |

See mold solutions in action at MetalTek’s process library.

Prime provides tailored mold builds using the above materials, depending on the part’s size, cycle life, and metallurgy.

FAQs

Q1: Which mold material lasts the longest?

A1: Hardened tool steels like H13 and S7, with proper maintenance, can exceed 1 million shots.

Q2: Is graphite a good mold material?

A2: Yes, for low-volume, high-temp casting of precious metals and alloys.

Q3: Can I reuse sand molds?

A3: Typically no. Each casting requires a new mold, but some cores can be reclaimed.

Q4: Are ceramic molds reusable?

A4: No. Ceramic molds are expendable and used for one casting only.

Q5: Can I use aluminum as a mold?

A5: Yes, but only for low-temp materials and low-volume runs.

Contact Information

Looking for expert guidance on mold materials for your next project?

- 🌐 Website: https://primecustomparts.com

- 📧 Email: [email protected]

We offer:

- Free mold material consultation

- 3D CAD and DFM support

- Fast lead times with ISO-certified quality

- Global shipping and documentation

Prime helps you choose the best mold material—so you get better parts, faster.

With 20+ years in custom tooling, we help global buyers build molds that last and perform under pressure. Whether you need H13 die molds or graphite casting tools, Prime delivers.