Top 10 Custom Mold Solutions for Metal Parts Manufacturing in 2025: What’s Leading the Industry Forward?

As manufacturers demand tighter tolerances, more complex geometries, and shorter cycles, traditional molds just don’t cut it anymore.

This guide breaks down the top 10 custom mold solutions transforming metal parts manufacturing in 2025. From AI-optimized design to hybrid tooling and MIM technology, these mold innovations are shaping the future of industrial production.

Explore what’s new, what works, and where global buyers are turning to get quality molds—fast, precise, and durable.

Table of Contents

- What is the future of injection moulding?

- Who is the father of injection molding?

- What are the new materials being used to make moulds nowadays?

- Which country is best for injection molding?

- FAQs

- Contact Information

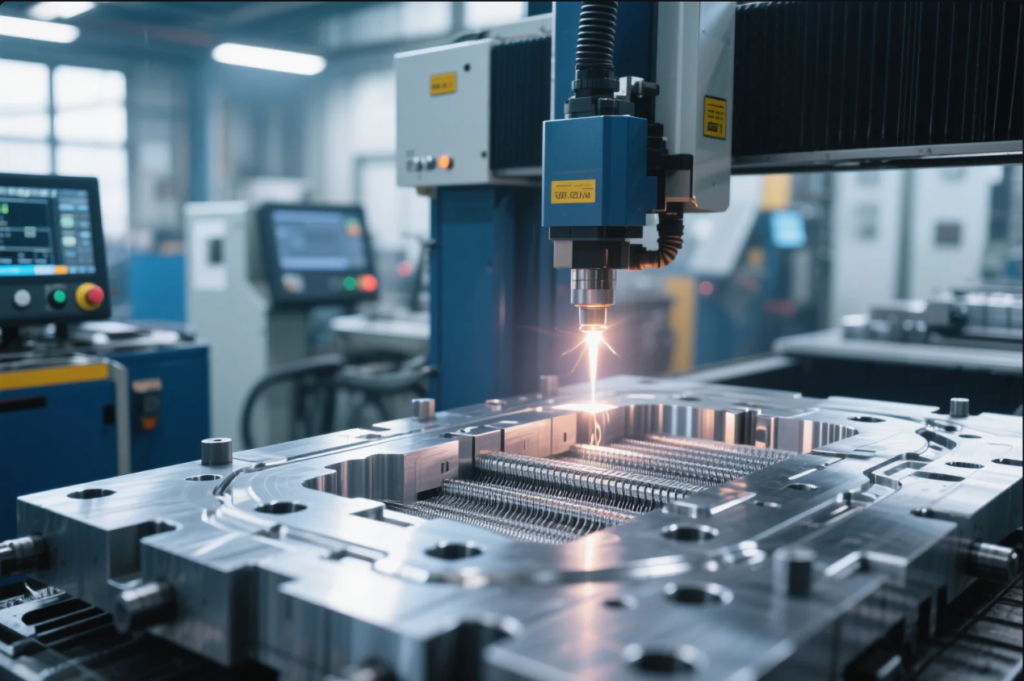

What is the future of injection moulding?

The injection molding process is evolving fast—especially in metal part production.

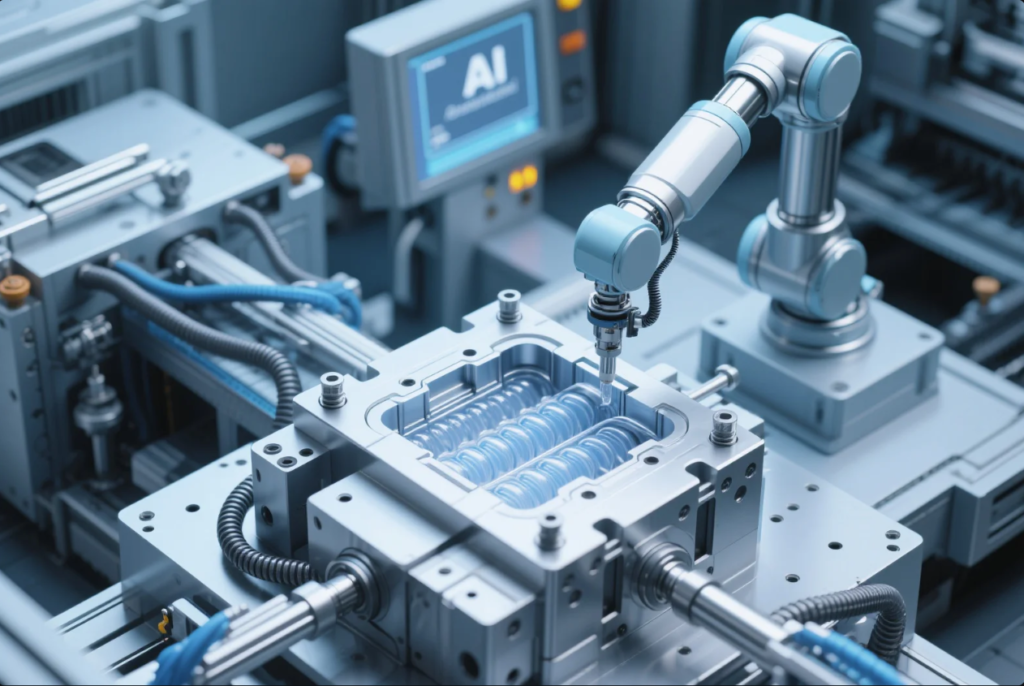

The future of injection molding lies in automation, smart sensors, simulation-driven design, and high-performance materials. In 2025, mold systems are integrated with AI to improve yield, predict wear, and shorten development cycles.

Future-Driven Mold Innovations

| Trend | Benefit |

|---|---|

| AI-Optimized Mold Design | Faster tooling with fewer trial shots |

| Embedded Sensors | Real-time temperature/pressure monitoring |

| Additive Manufacturing | Complex cooling channels, lower tooling cost |

| Multi-Material Tooling | Hybrid metal-plastic overmolds |

At Prime, we already use digital twins, CAM-integrated workflows, and ISO-level QA sensors on our production lines. This ensures faster iterations and better performance for every custom mold we build.

Check Moldex3D’s industry blog for more on future simulation tools.

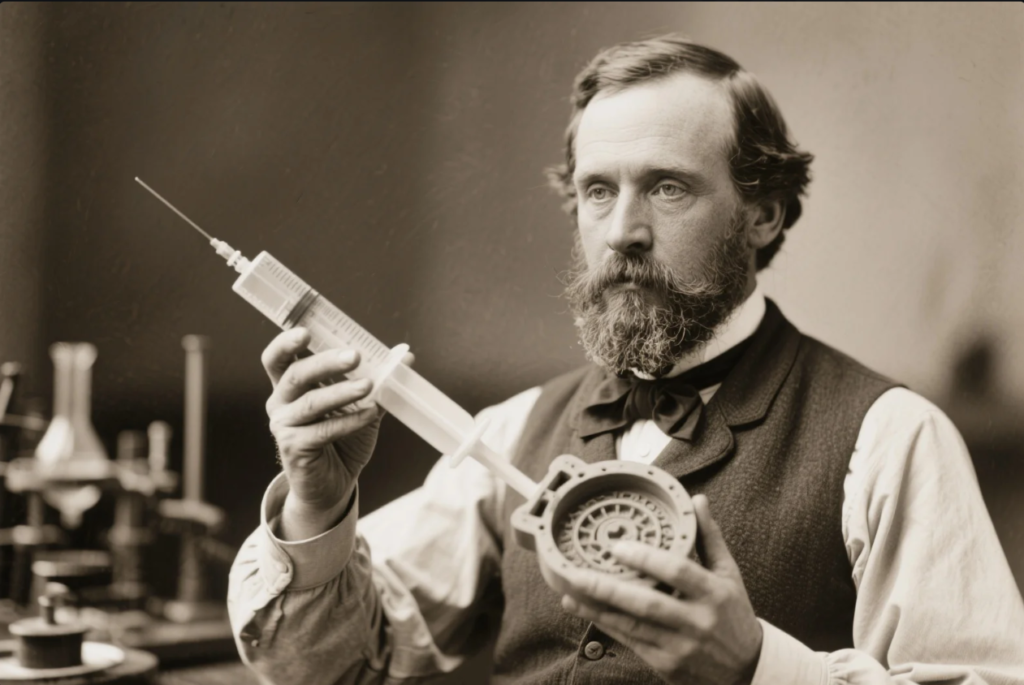

Who is the father of injection molding?

While injection molding is a cornerstone of modern manufacturing, its origin goes back more than a century.

John Wesley Hyatt is credited as the father of injection molding. In 1872, he patented the first injection molding machine to shape celluloid, laying the foundation for modern molding processes.

How Hyatt’s Legacy Continues Today

- He introduced the idea of shaping heated material using pressure and molds

- His invention enabled the first mass production of molded products

- Today, we apply the same principles—with high-speed machines, advanced alloys, and AI software

At Prime, we honor that legacy by combining proven principles with modern tech like MIM and multi-cavity die tooling.

What are the new materials being used to make moulds nowadays?

Today’s mold demands call for stronger, lighter, and more heat-resistant materials.

In 2025, new mold materials include AM-grade tool steels, ceramic composites, beryllium copper inserts, and hardened aluminum alloys. These allow higher durability, improved cooling, and better wear resistance.

Top Mold Materials in 2025

| Material | Use Case | Benefits |

|---|---|---|

| H13 Tool Steel | Die casting, MIM molds | High heat and wear resistance |

| Ceramic Inserts | High-temp, abrasive materials | Thermal shock and corrosion resistant |

| AM-Grade Steel (e.g., Maraging) | Conformal cooling and fast prototyping | Better design freedom and cycle time |

| Hardened Aluminum (7075-T6) | Short-run prototypes, precision casting | Lightweight, faster machining |

Prime offers molds built from these new materials based on your production specs. Need corrosion resistance? We recommend S136. Want speed? Go with aluminum + conformal cooling.

Which country is best for injection molding?

Location affects lead time, cost, and flexibility. Many buyers are rethinking where to build molds in 2025.

In 2025, China remains the top country for injection molding thanks to its unmatched blend of cost efficiency, engineering flexibility, and global-scale production.

Global Mold Supply Comparison

| Country | Strengths | Considerations |

|---|---|---|

| China | Cost-effective, rapid tooling, custom solutions | Must choose quality-certified supplier |

| Germany | Ultra-high quality, precision engineering | High cost, longer lead time |

| USA | Strong IP protection, fast rework | Higher tooling and labor cost |

| India | Competitive cost, basic tooling | Variable QC and limited complex tooling |

At Prime, based in China, we deliver tooling to buyers in 50+ countries with ISO certification, multi-language service, and flexible MOQ. Our molds are trusted by clients in automotive, electronics, and industrial automation.

FAQs

Q1: What’s the average mold lifespan in 2025?

A1: Steel molds (like H13) can last over 1 million cycles with proper maintenance. Aluminum molds last around 10,000–100,000 cycles.

Q2: Can I use 3D printing to make molds?

A2: Yes—for prototype tooling, insert cooling, or hybrid conformal channels in steel molds.

Q3: What’s the fastest mold lead time at Prime?

A3: 15–20 working days for rapid molds. Complex MIM tooling may take 25–30 days.

Q4: Are custom inserts or cooling designs possible?

A4: Absolutely. We offer beryllium-copper inserts, side actions, and mold flow simulations.

Q5: How do I verify mold quality before shipment?

A5: We offer T1 sample reports, full CMM inspection, video walkthroughs, and QA documents.

Contact Information

Looking for a trusted partner for your next custom mold?

- 🌐 Website: https://primecustomparts.com

- 📧 Email: [email protected]

We provide:

- Custom mold design consulting

- Full tooling development and sampling

- Global delivery and packaging

- Free DFM reviews and QA documentation

Choose Prime for durable, cost-effective, and fast-delivery custom mold solutions.

With over 20 years in the field, we help global buyers turn designs into production-ready molds—backed by ISO standards and responsive support.