Top Trends in Custom Mold Manufacturing for Industrial Metal Parts: What to Expect in 2025 and Beyond?

In today’s manufacturing world, precision is no longer optional—it's the baseline.

This article highlights the top emerging trends in custom mold manufacturing for industrial metal parts. From AI-driven design to next-gen MIM technology, we explore how global mold makers are pushing boundaries in 2025 and beyond.

If you're designing or sourcing custom tooling for casting, stamping, or CNC-formed components, this guide can help you stay competitive—and future-ready.

Table of Contents

- What is the future of metal injection molding?

- What is the future of injection molding?

- What are the 4 stages of injection molding?

- What is the mold making industry?

- FAQs

- Contact Information

What is the future of metal injection molding?

Metal Injection Molding (MIM) is set to play a key role in next-gen industrial design.

The future of metal injection molding is shaped by materials innovation, micro-size capability, and tighter integration with automated sintering and debinding. By 2025, MIM is expected to expand in sectors like medical, aerospace, and wearables.

Key MIM Trends

| Trend | Benefit |

|---|---|

| Fine Powder Control | Better flow and fill for tight geometry |

| Multi-Material Molding | Combines hard and soft metal in one mold |

| Integrated Sintering Cells | Faster production and fewer defects |

| Micro-MIM | Enables sub-millimeter part fabrication |

According to BASF's MIM division, newer feedstock like Catamold® improves precision while reducing sintering time.

At Prime, we offer custom MIM tooling, small-batch prototyping, and full-scale MIM part production with ISO-certified quality.

What is the future of injection molding?

Plastic and metal injection molding are both evolving rapidly.

The future of injection molding is built on AI optimization, digital twin simulations, sustainable materials, and hybrid molds. Automation reduces errors and speeds time-to-market, while cloud-based monitoring optimizes each cycle in real time.

What's New in 2025 Injection Molding

- AI-assisted mold fill, ejection, and cooling optimization

- Recycled material feedstock and sustainable polymers

- Conformal cooling channels from additive manufacturing

- Smart sensors tracking cavity pressure and mold wear

Companies like ENGEL and Arburg lead innovation in fully connected molding ecosystems.

Prime integrates simulation tools such as Moldex3D and CAMWorks in our custom mold development workflow for consistent mold quality.

What are the 4 stages of injection molding?

Every molding cycle, whether metal or plastic, follows the same core process.

The 4 stages of injection molding are: filling, packing, cooling, and ejection. Each stage affects part quality, cycle time, and tool wear. Precision in timing and temperature is essential for defect-free results.

Injection Molding Process Flow

| Stage | Description | Controlled By |

|---|---|---|

| Fill | Material enters mold cavity | Injection pressure, gate size |

| Pack | Additional material compresses and densifies part | Hold pressure, duration |

| Cool | Heat dissipates to solidify the part | Cooling lines, mold material |

| Eject | Finished part is removed from the mold | Ejector pins, draft angles |

Visit Wikipedia's injection molding process page for more technical details.

Prime optimizes all four stages using simulation and tool sensors to ensure high-yield production from the very first T1 shot.

What is the mold making industry?

Tooling is the backbone of modern manufacturing.

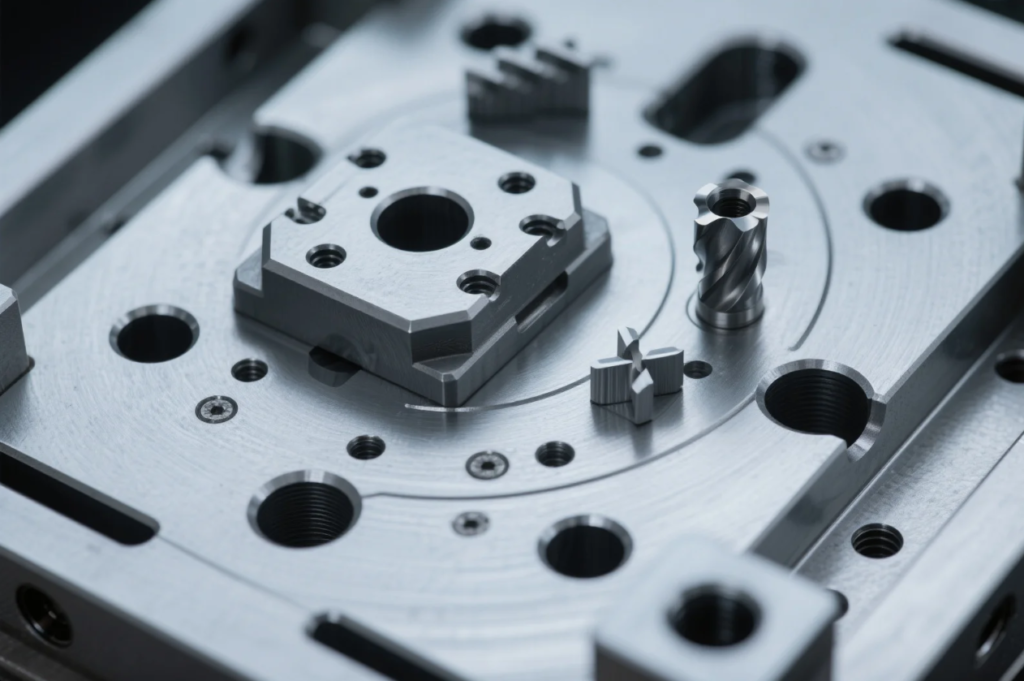

The mold making industry involves designing and producing tools that shape metal or plastic parts. It includes mold base machining, cavity/core fabrication, and integration with injection, casting, or stamping machinery.

Industry Scope and Segments

| Segment | Description | Tools Produced |

|---|---|---|

| Injection Mold Making | Plastic/metal part shaping via pressure | MIM molds, plastic injection molds |

| Die Casting Tooling | Molten metal molds with cooling channels | Aluminum/zinc die casting tools |

| Stamping Die Making | Sheet metal forming, blanking, piercing | Progressive and compound dies |

| Prototype Tooling | Fast, cost-effective soft tooling | Short-run aluminum molds |

According to MoldMaking Technology, global mold demand is rising in automotive, medical, and electronics sectors.

Prime offers in-house tooling with 5-axis CNCs, EDM, and CMM QA to support industrial clients worldwide.

FAQs

Q1: Which industries are driving mold innovation in 2025?

A1: EVs, aerospace, medical devices, and consumer electronics lead tooling innovation.

Q2: What materials are used in modern mold manufacturing?

A2: H13, S7, SKD11 steels, aluminum alloys, and ceramic composites.

Q3: Can Prime build molds for hybrid metal-plastic parts?

A3: Yes. We support insert molding, overmolding, and dual-shot mold tooling.

Q4: How does AI help with mold optimization?

A4: AI improves fill analysis, cycle prediction, cooling line layout, and tool wear prediction.

Q5: Is it possible to simulate part shrinkage before cutting steel?

A5: Absolutely. We offer shrinkage prediction, warpage analysis, and flow simulations with every mold design.

Contact Information

Ready to upgrade your mold supply strategy with future-proof solutions?

- 🌐 Website: https://primecustomparts.com

- 📧 Email: [email protected]

Our Offerings Include:

- Mold design with full simulation analysis

- Custom tools for MIM, die casting, stamping, and CNC parts

- Smart mold integration with cooling and QA feedback

- Rapid lead times and full documentation

Stay ahead in industrial mold innovation—partner with Prime for precision, speed, and durability.

Trusted by clients across North America, Europe, and the Middle East, Prime delivers custom mold solutions that evolve with your industry.