Top Tools and Technologies for Custom Metal Mold Making in 2025?

Poor tooling slows production and raises defect rates.

Custom metal mold making in 2025 demands modern tools, smart software, and advanced materials. These upgrades increase efficiency, precision, and consistency. Without them, factories risk delays, rework, and lost clients.

The right tooling makes or breaks your project. Let’s explore what’s essential this year.

Table of Contents

- What are the tools for molding?

- What do you use to mold metal?

- What are the new materials being used to make Moulds nowadays?

- What is needed to make a mold?

- FAQs

- Conclusion

What are the tools for molding?

Tooling mistakes cause downtime and product failures.

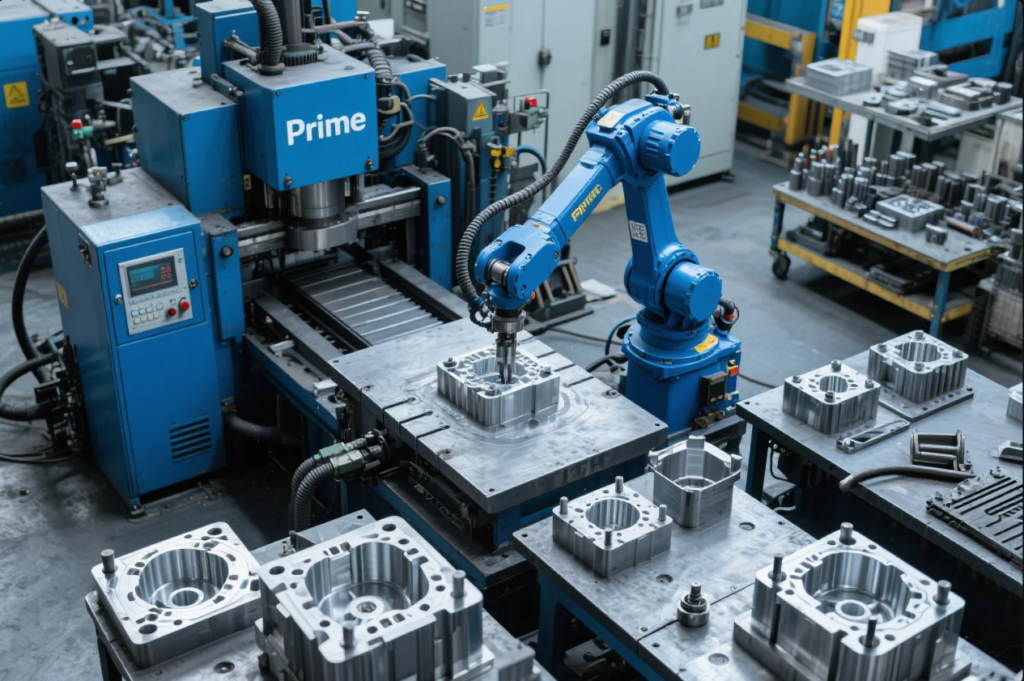

Mold making tools in 2025 include CNC machines, EDM systems, polishing stations, 3D scanners, and mold flow software. Each tool plays a vital role in ensuring dimensional accuracy and repeatability.

Precision starts with proper tools

At Prime, we combine 5-axis CNC machines and wire EDM to achieve ultra-precise cavity shapes. Tools like mold flow analysis software help simulate the injection process before metal even hits the mold.

| Tool | Purpose | Accuracy |

|---|---|---|

| CNC Machine | Shaping core and cavity | ±0.005 mm |

| EDM | Cutting hard-to-reach geometry | ±0.002 mm |

| Surface Grinder | Finishing flat surfaces | ±0.003 mm |

| Mold Flow Software | Flow simulation and stress check | Predictive |

Key takeaway

Use modern tools or fall behind. Precision tooling equals consistent products and fewer rejects.

What do you use to mold metal?

Wrong equipment leads to poor part quality and mold wear.

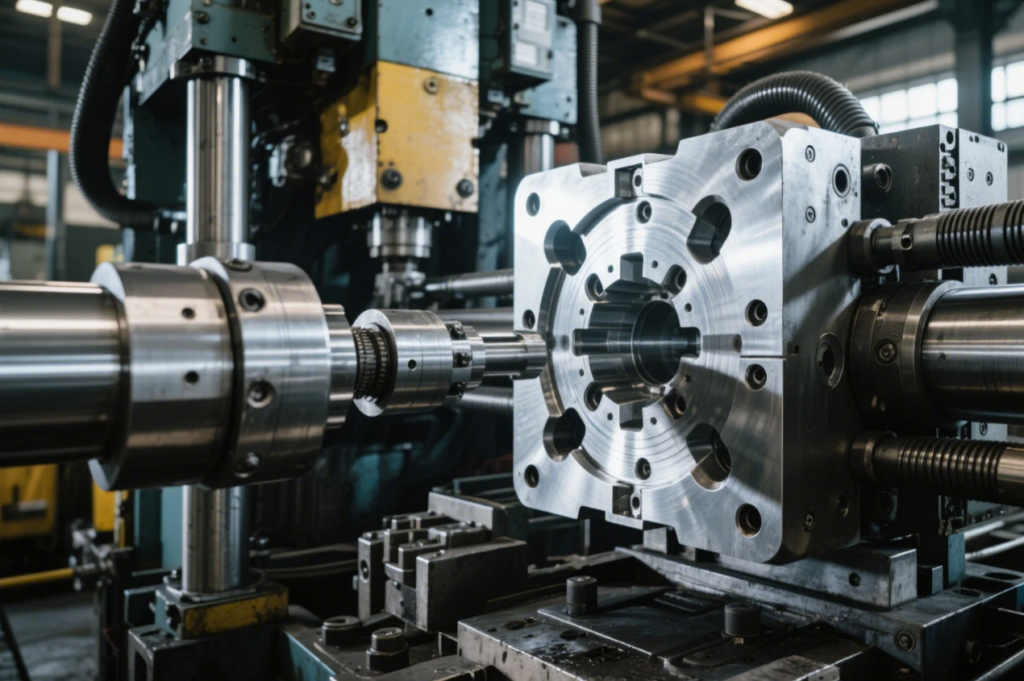

To mold metal, manufacturers use casting machines, die mold bases, high-heat ovens, and clamps. The method depends on the metal type and desired shape. Common techniques include sand casting, die casting, and investment casting.

Matching the metal to the method

Some metals like aluminum require quick cooling for strength. Others, like brass, need gradual cooling. At Prime, we choose equipment based on heat tolerance, flow rate, and shrinkage behavior.

| Metal Type | Common Method | Equipment Used |

|---|---|---|

| Aluminum | Die Casting | Die casting machine, mold base |

| Steel | Investment Casting | Wax patterns, ceramic shell oven |

| Brass | Sand Casting | Sand boxes, melting furnace |

Key takeaway

One process does not fit all. The right match of method and tool ensures quality and longevity.

What are the new materials being used to make Moulds nowadays?

Old mold steels crack under stress and heat.

Today’s mold makers use improved materials like H13 steel, beryllium copper, and additive-manufactured alloys. These materials offer better thermal stability, wear resistance, and machinability.

New materials mean longer tool life

Prime has replaced over 70% of our old P20 mold bases with newer grades like H13 and S136. These handle repeated thermal cycling without cracking. Beryllium copper offers great thermal conductivity, making it ideal for insert areas.

| Material | Benefit | Application Area |

|---|---|---|

| H13 Steel | Heat resistance | Core/cavity of high-pressure molds |

| S136 Stainless | Corrosion resistance | Precision plastic molds |

| Beryllium Copper | Fast heat transfer | Cooling channels/inserts |

| AM alloys | Complex geometry, faster cooling | Lightweight inserts |

Key takeaway

Better mold materials lower downtime. Investing in quality steel pays off in high-volume runs.

What is needed to make a mold?

Lack of preparation causes costly mold failures.

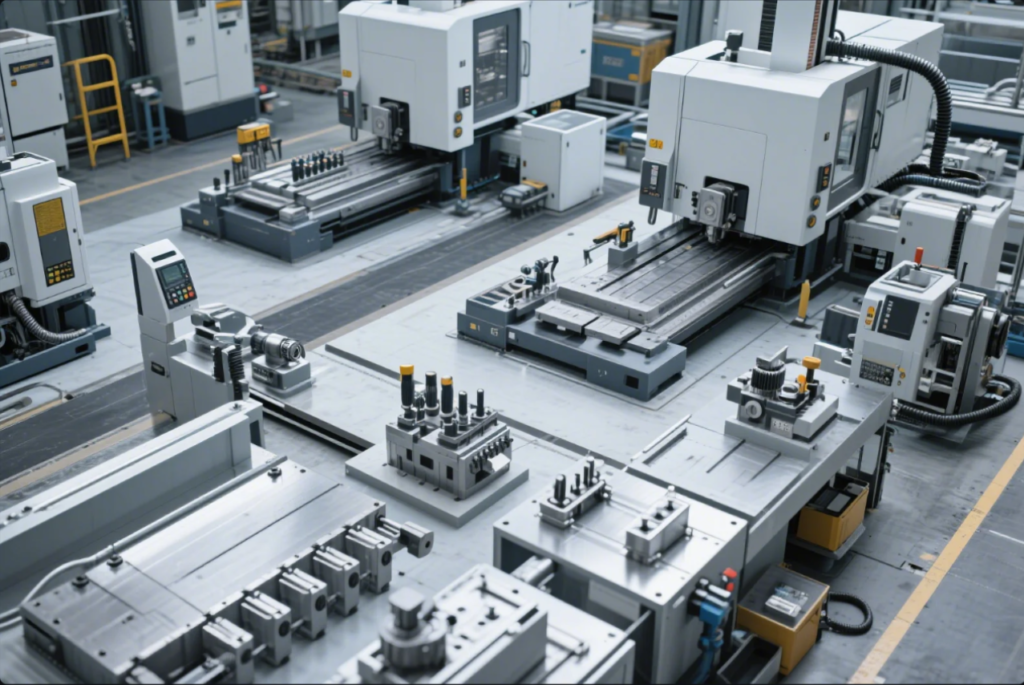

To make a mold, you need a 3D CAD design, mold material, precision machines, skilled workers, and QA tools. Each step—from design to polishing—must follow strict tolerances and checks.

Mold making is a team effort

At Prime, the process begins with CAD modeling, followed by simulation, machining, fitting, polishing, and inspection. Without full control over every stage, quality slips.

| Stage | Task | Tools Used |

|---|---|---|

| Design | Create 3D geometry | CAD software, mold flow simulation |

| Machining | Cut cavity/core shapes | CNC, EDM, grinders |

| Assembly | Fit and test components | Torque tools, test gauges |

| Polishing & QA | Final finish and inspection | Micrometers, surface testers, CMMs |

Key takeaway

Skipping any stage leads to defects. A reliable mold maker follows every step with precision.

FAQs

What’s the most accurate tool for mold shaping?

Wire EDM gives the highest precision, especially for internal corners and thin slots.

What’s the best material for high-temperature molds?

H13 tool steel offers excellent heat resistance and durability under thermal stress.

Can 3D printing be used in metal mold making?

Yes. Additive manufacturing is used to make inserts and cooling channels faster.

How does Prime ensure accuracy?

We use CMM machines and optical inspection to ensure tolerances stay within 0.01 mm.

Do I need a full mold or just inserts?

It depends. For low-volume production, modular inserts can save time and cost.

Conclusion

Modern tools, smart materials, and expert processes define custom mold making in 2025.

Need custom mold making with fast delivery and ISO quality?

📩 Email us at: [email protected]

🌐 Visit: https://primecustomparts.com

We respond quickly, deliver on time, and build molds that last.