Top 6 Cost Factors That Affect Custom Metal Mold Pricing in 2025?

Mold pricing in 2025 continues to challenge manufacturers, especially those scaling globally.

Custom metal mold pricing is no longer just about steel and machining—it's shaped by global steel prices, mold complexity, machining time, surface finish, packaging, and compliance costs. Companies sourcing internationally must understand these cost factors to reduce waste, improve ROI, and stay competitive.

Here’s a complete breakdown of the six primary pricing drivers in custom mold manufacturing—and how to control them.

Table of Contents

- 1. Material Type & Global Steel Prices

- 2. Mold Design Complexity & Cavity Count

- 3. Machining Time & Equipment Selection

- 4. Mold Lifespan & Hardened Steel Alloys

- 5. Surface Finish & Tolerance Requirements

- 6. Logistics, Packaging & After‑Sales Support

- FAQs

- Conclusion

1. Material Type & Global Steel Prices

The type of tool steel used has the highest influence on the mold’s base cost. Prime uses only certified steel from global providers and provides mill test certificates (MTC) with every project.

| Grade | Common Use | Cost/kg (USD) |

|---|---|---|

| P20 | Medium-volume injection molds | \$3.20–\$3.80 |

| H13 | Die casting and long-life molds | \$4.20–\$5.00 |

| S136 | Medical/optical mold components | \$6.50–\$7.50 |

Consider cost-effective alternatives like aluminum 7075 for prototype molds to reduce startup expenses by 40%.

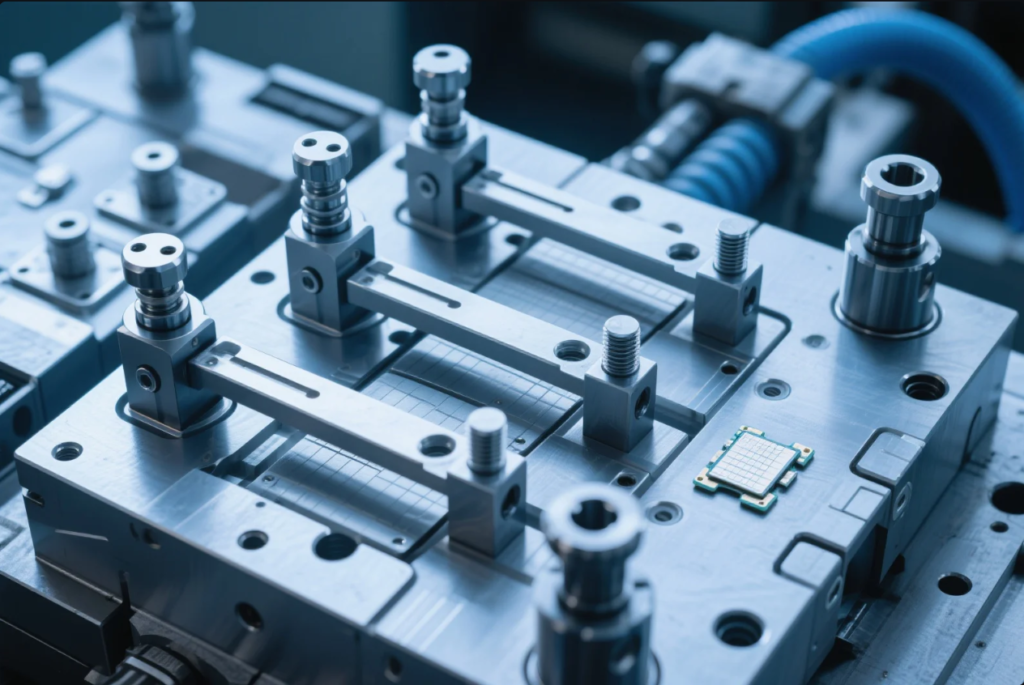

2. Mold Design Complexity & Cavity Count

Highly complex injection mold designs involve intricate lifters, undercuts, and custom side actions that raise both design and machining time.

| Configuration | Cavities | Approximate Cost (USD) |

|---|---|---|

| Single-cavity | 1 | \$7,000 – \$12,000 |

| Multi-cavity standard | 4 | \$18,000 – \$30,000 |

| Multi-cavity complex | 8+ | \$40,000 – \$70,000+ |

DFM optimization during early planning is critical. Prime offers Design for Manufacturability audits to reduce redundant geometry, often cutting costs by 15–25%.

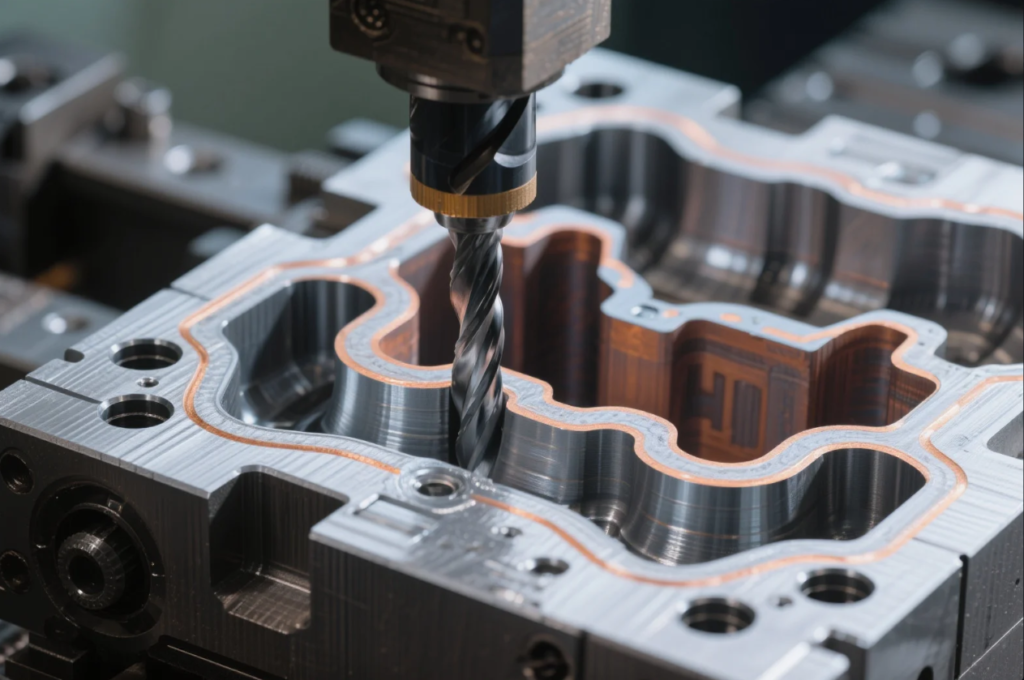

3. Machining Time & Equipment Selection

Machining time varies based on:

- Machine type

- Number of tool changes

- Tolerance requirements

| Machine Type | Hourly Rate (USD) |

|---|---|

| 3-axis CNC | \$30–\$45 |

| 5-axis CNC | \$55–\$90 |

| Wire/Sinker EDM | \$40–\$70 |

Prime’s CNC programming reduces pass count and tool wear, reducing cost. High-precision needs may require multiple EDM setups, which can double time. For details, see CNC machine cost analysis.

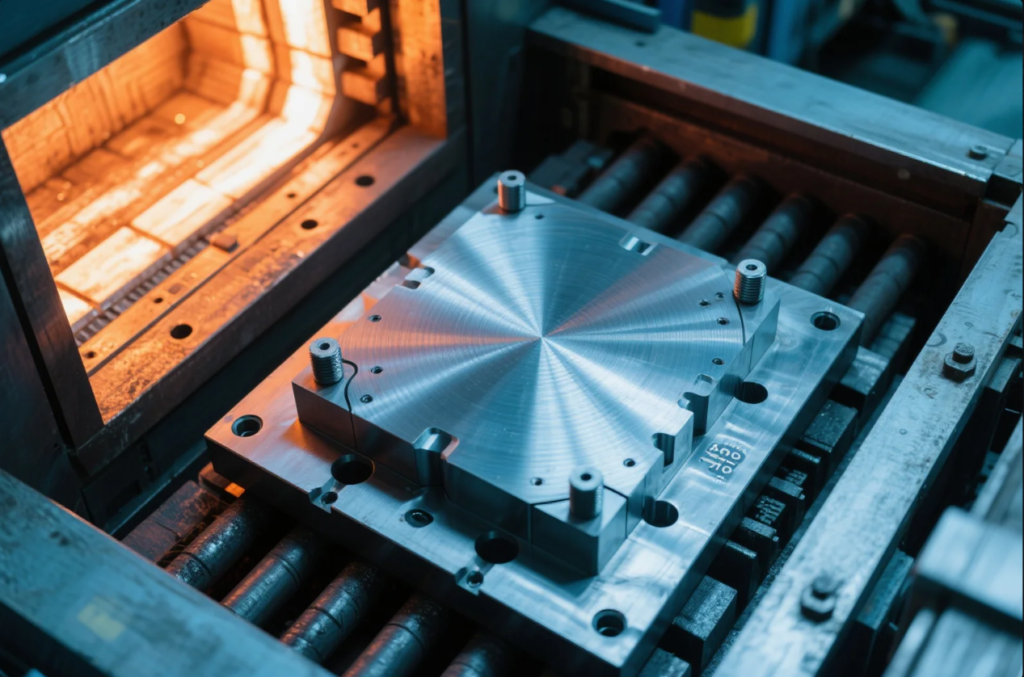

4. Mold Lifespan & Hardened Steel Alloys

Cost Factors That Affect Custom Metal Mold Pricing.The mold class defines its cost and expected life. See SPI mold classifications for guidance:

| Mold Class | Life (Est.) | Material Used |

|---|---|---|

| Class 105 | <500 cycles | Aluminum 7075 |

| Class 103 | 100K–300K | P20 |

| Class 101 | 1M+ | H13 / S136 |

Harder steel lasts longer, but also costs more to machine and polish. Choose materials based on part volume forecast and part complexity.

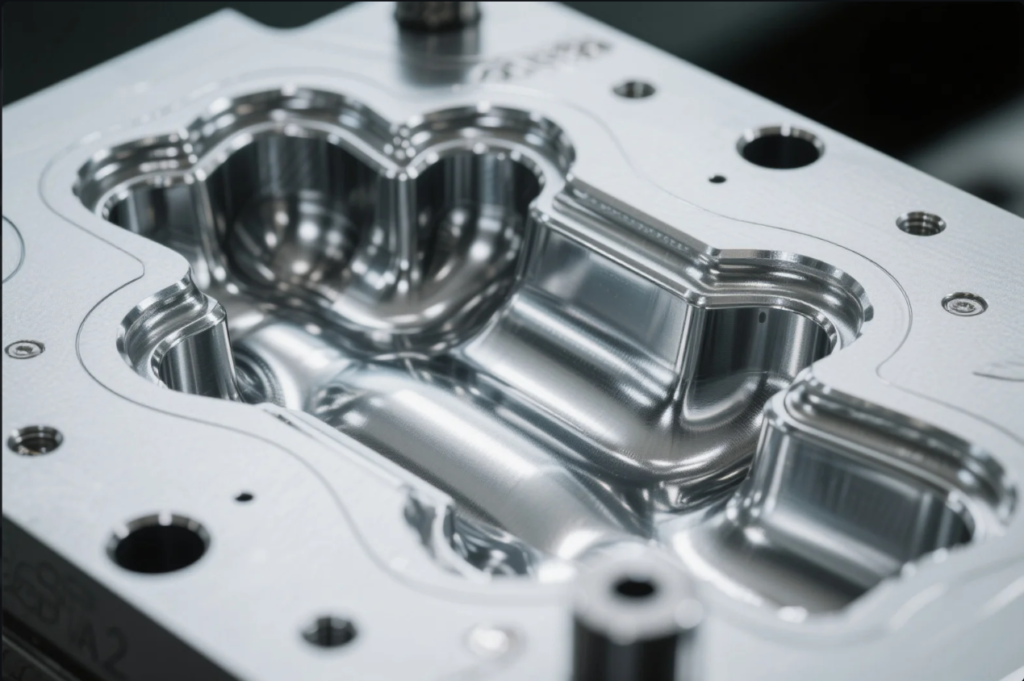

5. Surface Finish & Tolerance Requirements

For cosmetic and optical applications, tight tolerance and fine surface roughness are a must.

| Finish Grade | Tolerance Impact | Cost Level |

|---|---|---|

| SPI-C1 (Matte) | ±0.05 mm | Low |

| SPI-B2 (Smooth) | ±0.01 mm | Moderate |

| SPI-A2 (Mirror) | ±0.005 mm | High |

High-polish parts (like light guides) require hand finishing and multiple rechecks using CMM validation.

6. Logistics, Packaging & After‑Sales Support

Post-production costs include:

- Wooden crates & rust-proof sealing

- Export compliance (e.g., ISPM-15 wood)

- DDP or CIF delivery

- Sample trial shipment

- Remote install or video call support

Prime offers DDP shipping and documents like PPAP FAI reports to ensure seamless import compliance.

FAQs

Q: What is the future of metal injection molding?

The market is expanding into medical implants, precision gears, and aerospace. New materials like titanium alloys and automation in sintering are transforming MIM economics.

Q: What is the average cost for a metal mold?

Ranges from \$6,000 (aluminum prototype) to over \$70,000 for a hardened, multi-cavity mold. You can calculate your costs with Prime’s online RFQ system.

Q: Why are injection molds so expensive?

They involve custom steel, multi-axis CNC and EDM operations, precision polish, testing, documentation, and international shipping.

Q: How to reduce custom mold cost?

Start with a DFM consultation, choose optimal mold class, avoid over-specifying tolerances, and simplify lifter/slides if not critical.

Conclusion

Custom mold costs vary, but with clear insight into pricing levers, you can plan smarter, faster, and more affordably.

📩 Want an instant mold cost evaluation? Email us at [email protected]

🌐 Visit our official site: https://primecustomparts.com

We at Prime are your trusted custom injection mold supplier, ISO 9001 certified, with over 30 years in global mold delivery. We help clients from the US, EU, and Middle East build cost-effective, durable tooling on time—every time.