Best-Rated Custom Metal Molds for Electronics Manufacturing in 2025?

Electronics makers demand tighter tolerances and faster cycle times. Poor-quality molds lead to costly defects and delays.

Custom metal molds are critical for producing complex electronic components efficiently. Choosing the right mold supplier changes everything.

Let’s explore the best mold makers, machine brands, pricing insights, and career opportunities in 2025.

Table of Contents

- Who is the best mold maker in China?

- Who makes the best injection molding machines?

- How much does a manufacturing mold cost?

- Is injection molding a good career?

- FAQs

- Conclusion

Who is the best mold maker in China?

Finding a mold supplier that delivers both precision and fast lead times is challenging. Many claim capabilities they don’t have.

In 2025, the best mold makers are those with in-house CNC, ISO 9001 certification, and experience in high-spec industries like electronics and automotive.

Key Qualities of Top-Rated Mold Makers

| Feature | Description |

|---|---|

| ISO Certification | Ensures quality consistency and audit trail |

| CNC In-House | Faster tolerance control and flexible modification |

| Global Export Experience | Familiar with customs, labeling, packaging, and certifications |

| Multi-Process Integration | Covers stamping, casting, welding, machining in one plant |

| DFM Engineering Support | Helps optimize customer CAD files to reduce mold cycles |

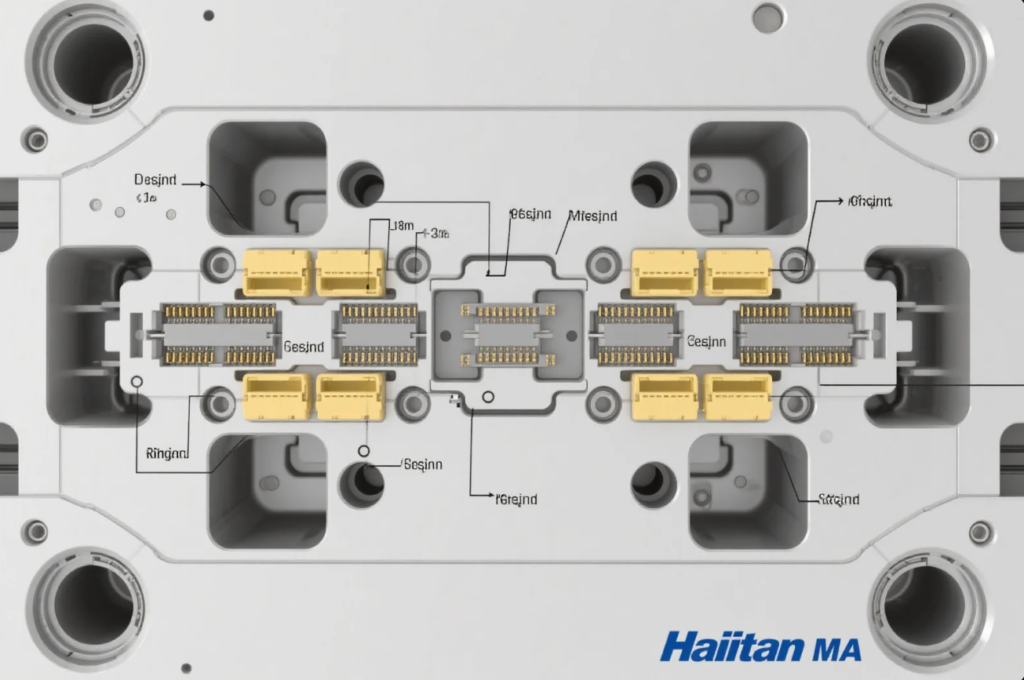

Prime, based in Shandong, China, stands out for its ability to produce multi-cavity custom metal molds for electronics with ±0.01mm tolerance. Our team helped a German electronics OEM reduce their defect rate by 43% after switching from an offshore trader to our in-house CNC-finished tool steel molds.

We work with buyers across 30+ countries. For a wider list of vetted suppliers, explore Alibaba’s verified mold manufacturers or Made-in-China’s mold listings.

Who makes the best injection molding machines?

A mold is only as good as the machine that runs it. And for electronic part makers, this is especially critical.

Top machines in 2025 include Haitian, Engel, Arburg, and Sumitomo-Demag—known for repeatability, speed, and automation compatibility.

Leading Brands Overview

| Brand | Origin | Strengths |

|---|---|---|

| Haitian | China | Affordable, reliable for mass production |

| Engel | Austria | Best-in-class automation and real-time monitoring |

| Arburg | Germany | Superior micro-molding and high-viscosity performance |

| Sumitomo-Demag | Japan/Germany | Electric drives, cleanroom certified |

We frequently design CNC injection mold tooling for these machines. For example, one client using Engel victory series cut energy costs by 20% after upgrading to aluminum-core molds designed by Prime.

We also offer simulation support to ensure your molds match press performance. For detailed machine specs, browse Haitian's product site or read insights from Plastics Technology.

How much does a manufacturing mold cost?

Many clients ask us: “Why does mold cost vary so much?” The answer lies in five key cost drivers—part complexity, material, cavities, finish, and tolerance.

Most small-to-mid volume electronics molds fall between \$3,000 to \$25,000, depending on specifications.

Mold Cost Breakdown (2025 Rates)

| Mold Type | Price Range (USD) | Example Applications |

|---|---|---|

| Prototype CNC Mold | \$1,000 – \$3,000 | Early-stage PCB housings |

| Single Cavity Tooling | \$4,000 – \$12,000 | Enclosures, EMI covers |

| Multi-Cavity Steel Mold | \$15,000 – \$60,000 | USB connectors, adapters, power bricks |

| Insert/Overmold Tooling | \$5,000 – \$20,000 | Cable overmolds, heat sinks |

A US buyer of consumer electronics recently shared that their old mold failed after 10,000 shots. We replaced it with a P20 tool steel mold with beryllium inserts—doubling life cycle while cutting changeover time.

Want to calculate a mold budget? Use the Xometry mold cost calculator or check out Fictiv’s pricing guide.

Is injection molding a good career?

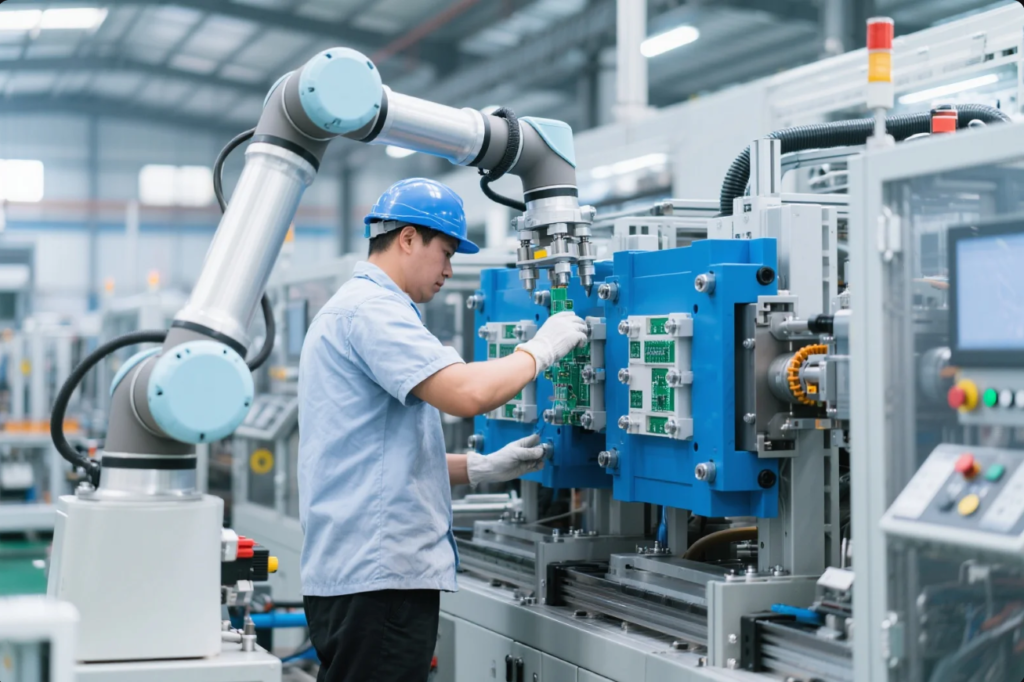

Injection molding isn’t just a factory job anymore—it’s a gateway into smart manufacturing, design thinking, and robotics.

The field offers career growth from technician to designer to automation engineer. With IoT, AI, and lean practices entering molding, demand is booming.

Molding Career Path in 2025

| Role | Core Skills | Annual Salary (US average) |

|---|---|---|

| Mold Technician | Setup, troubleshooting, quality | \$45,000–\$60,000 |

| CNC Programmer | CAM software, GD\&T, finishing | \$55,000–\$70,000 |

| Mold Designer | CAD, steel grades, DFM | \$65,000–\$85,000 |

| Process Engineer | Machine calibration, SPC, lean | \$75,000–\$100,000+ |

Top firms like Husky Injection Molding and Milacron actively recruit new talent. You can also explore injection molding job trends via Indeed.

Check the Wikipedia article on injection molding for background knowledge.

FAQs

1. What’s the best mold type for electronics?

We recommend aluminum molds with hardened steel inserts for small-batch, and full P20/NAK80 steel for high-volume electrical housings.

2. What’s your minimum order quantity?

We support MOQs as low as 100 pcs for new designs. Perfect for startups and prototyping.

3. What materials do your molds support?

We work with ABS, PC, PBT-GF, PPS, and metal overmolds like aluminum and zinc.

4. Can you assist with mold design?

Yes. We provide free DFM feedback and can support file formats including STEP, IGES, STL, and SolidWorks.

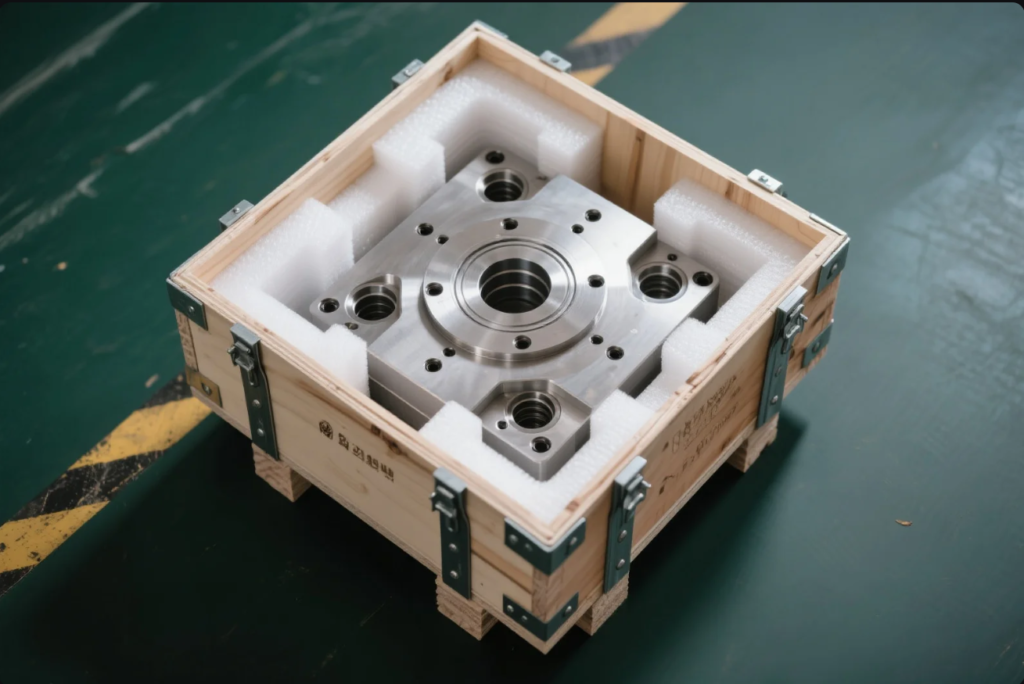

5. Do you provide packaging and customs documents?

Yes. All orders include foam-filled export crates, HS codes, CO, and shipping documentation.

Conclusion

Custom molds power the electronics industry. Choosing the right mold shop ensures faster production and fewer risks.

Partner with Prime, one of China’s most trusted custom metal mold suppliers for electronics. We offer free consultations, quick quotes, and ISO-certified quality.

📞 Email: [email protected]

🌐 Website: https://primecustomparts.com

Let’s build your next breakthrough—one mold at a time.