Top Custom Welding Service Providers for OEM and Industrial Applications

Welding is a cornerstone in OEM and industrial manufacturing chains. High-quality welds ensure product reliability and seamless assembly.

In 2025, leading welding providers offer turnkey OEM-ready solutions—covering MIG, TIG, robotic, laser welding—backed by robust certifications and global shipping expertise.

This detailed guide covers welding methods, equipment suppliers, cost analysis, workforce insights, and top service providers in the custom welding space.

📋 Table of Contents

- Which Welding Method Do OEMs Use?

- Who Is the Leading Welding Equipment Manufacturer?

- What Does Custom Welding Really Cost?

- Who Employs the Most Welders?

- Top Custom Welding Providers for OEM

- Prime Custom Parts: Your OEM Welding Partner

- FAQs

- Contact Prime

Which Welding Method Do OEMs Use?

OEM manufacturers prioritize consistency, precision, and material integrity. The widely used welding technologies include:

- MIG (GMAW) – Fast, efficient for heavy steel frames and general assembly.

- TIG (GTAW) – clean, precise, and used for stainless, aluminum, and aerospace parts.

- Robotic Welding – Offers repeatable quality and high efficiency; ideal for automated production lines.

- Laser Welding – Ultra-fine welds with minimal distortion (e.g., Trumpf laser welding systems) source.

- Friction Stir Welding (FSW) – Excellent for aluminum and dissimilar metal joins in EV and aerospace parts source.

Each technique fits specific OEM needs—from structural integrity to cosmetic requirements.

Who Is the Leading Welding Equipment Manufacturer?

High-standard equipment ensures stable performance and quality outcomes. The top global welding equipment manufacturers are:

- Lincoln Electric – World-leading manufacturer for arc, MIG, TIG, and robotic systems.

- Miller Electric – Known for tough industrial and portable welding systems.

- ESAB – Comprehensive arc welding solutions used worldwide.

- Fronius – Specialists in TIG and digital welding technology with monitoring loops.

- Weihai CIG (CIGWELD) – Major China-based welding equipment supplier for APAC markets.

OEMs depending on these brands achieve reliable, repeatable weld performances.

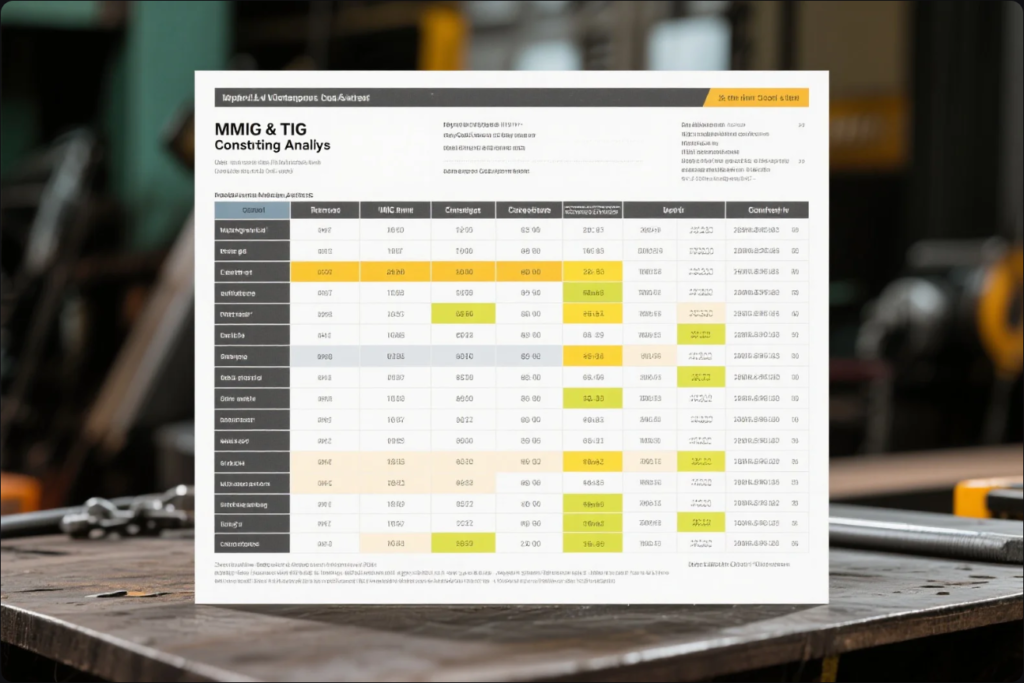

What Does Custom Welding Really Cost?

Custom welding expenses depend on:

- Material Costs – Stainless steel adds \~30–50% overhead vs. mild steel.

- Welding Type – TIG runs at higher costs per minute compared to MIG; robotic cells involve significant initial investment (\~\$50k–150k) source.

- Labor & Overheads – shop labor ranges from \$50–125/hr in developed markets, \$7–12/hr in China.

- Finishing & QC – shot-blasting, painting, and dimensional inspection: \$5–20 per unit.

- Fixtures/Tooling – one-time cost \$200–\$1,000 amortized across production runs.

Sample Unit Pricing (FOB China or U.S. shop rate)

| Part Type | Welding Process | Quantity | Price Range (USD) |

|---|---|---|---|

| Mild steel bracket | MIG | 100 | \$20–\$30 |

| Stainless steel panel | TIG | 100 | \$45–\$65 |

| Robotic weld chassis | MIG robotic automation | 200 | \$50–\$120 |

| CNC-finished welded housing | MIG + CNC trimming | 500 | \$75–\$150 |

Shops in high-wage countries like the U.S. charge up to \$95/hr for complex TIG jobs source.

Small units may offset costs with higher tooling charges upfront.

Who Employs the Most Welders?

Welding remains a strong, essential trade:

- The U.S. employs \~454,500 welders, with stable job growth projected source: U.S. Bureau of Labor Statistics.

- Over 60% of welders work in manufacturing and fabrication shops globally.

- Average pay ranges from \$50–65k/year in North America; top earners make \$100/hr+.

- Welding jobs in EU, Canada, Australia, and Japan have grown 4–8% in recent years.

Seeking mobility or technical trades? Welding remains a strategic and well-compensated path.

Top Custom Welding Providers for OEM

Here are seven distinguished welding providers offering OEM-grade performance globally:

| Company | Highlights |

|---|---|

| Prime Custom Parts (China) | MIG/TIG/robotic welding, CNC trimming, powder coat, export packaging |

| Lincoln Electric | Welding kits, training, robotic hardware |

| Miller Electric | Rugged welding gear used in OEM lines |

| ESAB | Arc welding systems and consumables |

| Fronius International | High-precision TIG systems with quality controls |

| Tianjin Golden Bridge (China) | Welding wire manufacturer and OEM welding lines |

| Voestalpine Böhler Welding (Austria) | Welding technology and consultancy services |

Each brand plays a key role, from machinery to consumable materials and turnkey welding solutions.

Prime Custom Parts: Your OEM Welding Partner

Founded in 1993, Prime has dispatched OEM components globally across North America, EU, Australia, and the Middle East.

Why Prime Is a Trusted Welding Source

- Ten production lines: MIG, TIG, spot, robotic welding backed by AWS/ISO certifications.

- Full fabrication: Laser/plasma cutting (Trumpf/Trumpf-type), CNC trimming, tapping fixtures.

- Finishing & Packaging: Powder coating, quality inspection, crate labelling, global shipping.

- Customer responsiveness: RFQ responses within 24 hours; sample production in 15 days; batch shipping in 30 days.

- Inclusive support: DFM consultations, 2D/3D review, pack documentation, languages: English/Spanish/Arabic included.

✅ Pro Tip: OEMs and system integrators benefit from Prime’s seamless weld, finish, and assemble service under global shipping terms: FOB/DDP/CIF.

FAQs

Q1: Which welding method is best for OEM structural parts?

Robotic MIG ensures strong, repeatable welds for large components.

Q2: Can I buy welding equipment and contracted welding services together?

Yes—Prime supports consultancy and supplies machines and weldments on request.

Q3: Is robot welding expensive?

Initial costs are \$50k–150k, but unit cost drops significantly above \~200 parts.

Q4: Is welding still a stable career choice?

Yes—global demand and competitive pay levels underscore welding as a sound trade.

Q5: How do OEMs ensure weld quality?

Check for ISO 3834, AWS-certified welders, porosity testing, dimensional inspection, and batch documentation.

📞 Contact Prime

Need reliable OEM welding support—precision, scale, and professionalism?

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

- RFQ responses within 24 hours

- Complete welding and fabrication services

- Certified quality, export-ready packaging

- Production lead times: 15–30 days

👉 Engage our team today—get rapid quotes and start efficient OEM welding production.