Top Custom Welding Shops Offering Precision Parts for Heavy Industry

When your heavy-industry project depends on welding accuracy, strength, and on-time delivery, the right welding shop is essential.

In 2025, top welding providers combine ultra-precise MIG, TIG, orbital, and laser welding with CNC finishing, CMM validation, and export-grade packaging.

📋 Table of Contents

- What Is the Most Precise Welding Method?

- Who Is the Leading Manufacturer of Welding Equipment?

- Which Weld Type Is Best for Precision?

- How Much Does Custom Welding Cost?

- Top Precision Welding Shops for Heavy Industry

- Prime Custom Parts: Precision Welding Partner

- FAQs

- Contact Prime

What Is the Most Precise Welding Method?

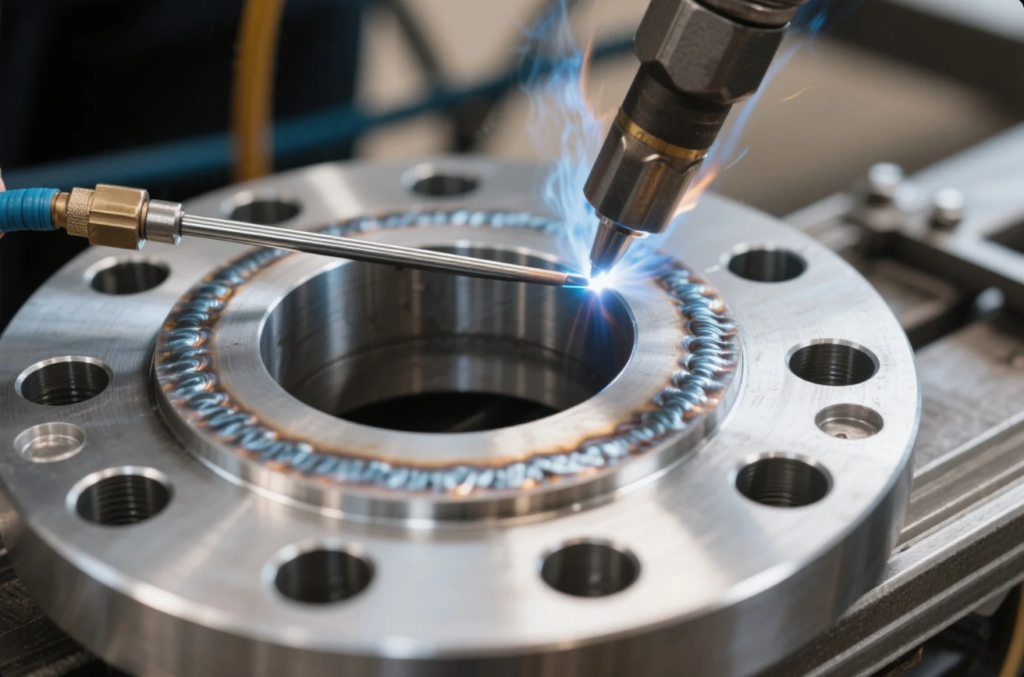

Laser welding and orbital TIG are the top precision methods:

- Laser Welding delivers micron-level accuracy with ultra-low distortion, ideal for electronics and high-end industrial parts (see Trumpf laser systems).

- Orbital TIG Welding provides uniform, automated welds around pipes and tubes—perfect for pressure vessels.

- Micro-TIG offers precision for very fine or miniature components used in medical and toolmaking industries.

These methods are indispensable in sectors like aerospace, power generation, oil & gas, and precision manufacturing.

Who Is the Leading Manufacturer of Welding Equipment?

Top equipment brands empower precision welding workshops:

- Lincoln Electric – Leading brand offering MIG, TIG, orbital and robotic systems.

- Fronius – High-precision TIG and arc-control systems.

- Trumpf – Premier industrial laser welding platform.

- Amada Weld Tech – Micro-TIG and laser welding solutions often used for high-precision tooling.

- ESAB – Global leader in arc welding and welding automation.

These brands are frequently found in top-end precision welding shops around the world.

Which Weld Type Is Best for Precision?

High-precision welding methods include:

- Orbital TIG Welding for perfect circular welds used in pipes, boss joints, and vessels.

- Laser Welding for tight, low-distortion seams in thin parts.

- Micro‑TIG for extremely fine, small-scale applications.

- Pulsed MIG/TIG for controlled bead shape on mid-thickness components.

For heavy-industry parts demanding tight tolerances, orbital TIG and laser welding are the gold standards.

How Much Does Custom Welding Cost?

Cost factors include:

- Equipment Setup: orbital TIG systems cost \$30,000–80,000; laser setups exceed \$150,000.

- Labor: \$50–150/hr in NA/EU; \$15–30/hr in Asia.

- Material: stainless costs \~30–50% more than mild steel.

- Finishing & QC: add \$5–30 per part.

- Tooling: one-time fixture setup of \$300–\$1,200.

Sample pricing (FOB):

| Part Type | Welding Method | Qty | Unit Price (USD) |

|---|---|---|---|

| Pressure vessel stub | Orbital TIG | 50 | \$200–\$350 |

| Precision housing piece | Laser welding | 100 | \$150–\$300 |

| Heavy plate bracket | Robotic MIG | 300 | \$60–\$120 |

Higher volumes reduce unit cost through amortization of setup and tooling expenses.

Top Precision Welding Shops for Heavy Industry

| Welding Shop | Location | Precision Specialty |

|---|---|---|

| Prime Custom Parts | China | Orbital TIG, laser, MIG, CNC finishing, export packaging |

| Lincoln Electric Automation Division | USA | Orbital robots, welding lines, process training |

| Dahl Welding Engineering | Canada | Weld joint design, automation, procedural solutions |

| Trumpf Laser Welding Centers | Germany | Laser weld components for automotive & machinery |

| Inductotherm Heating & Welding Ltd | UK | Induction & heavy-plate seam welding for industrial sector submissions |

| Inrotech A/S | Denmark | Robotic welding modules for shipbuilding and heavy fabrication |

Each excels in delivering precision-focused welding solutions for heavy industry, supported by advanced equipment and process controls.

Prime Custom Parts: Precision Welding Partner

As a strategic partner since 1993, Prime delivers critical welding components to automotive, energy, aerospace, and industrial OEMs.

Prime's Capabilities:

- Orbital TIG and laser cells with tight process control

- Trumpf-style laser cutting and CNC trimming

- MIG/robotic weld stations with multi-axis automation

- CMM measurements and weld macro-section reporting

- AWS- and ISO-qualified welders; fully traceable welding records

- Custom export packaging with foam, crates, labels; DDP/FOB/CIF logistics

- Fast turnarounds: 24-hour RFQ, 15-day prototype, 30-day production lead

📩 Get started: Send your 2D/3D drawings for a free engineering review and quote.

FAQs

Which method is best for pipe welds?

Orbital TIG delivers consistent, full-penetration welds on pipes and flanges.

Is laser welding cost-effective?

Upfront cost is high, but with high throughput and low defect rates, costs per part decrease significantly.

How to ensure weld accuracy?

Require certifications (ISO 3834, AWS), CMM logs, macro photos, and full QA documentation.

Can shops handle combined welding processes?

Yes—Prime integrates orbital TIG, laser, MIG robotic, CNC trimming, and finishing in one facility.

Contact Prime

Ready for precision welding with OEM-level quality?

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

✔ RFQ responses within 24 hours

✔ Prototypes ready in 15 days

✔ Full batches in 30 days

✔ Documentation, packaging, and logistics included

✅ Start your precision welding project today—direct to production.