Top 10 Custom Metal Casting Parts Manufacturers for Precision Components in 2025

📄 Table of Contents

- Which is the most widely used metal for casting?

- What are the items that can be done through casting?

- Which is an example of casting?

- What is the most popular process of metal casting called?

- Top 10 Custom Metal Casting Manufacturers in 2025

- What makes a supplier ideal for precision metal casting?

- Best practices when sourcing metal cast parts

- FAQs

- Conclusion

Which is the most widely used metal for casting?

Gray iron is the most used casting metal worldwide. It’s affordable, easy to machine, and offers excellent vibration damping. Typical applications include automotive engine blocks and industrial machinery bases.

Aluminum is also widely used. It’s lighter than iron, resists corrosion, and works well in aerospace and automotive parts.

What are the items that can be done through casting?

Casting supports a wide variety of products, such as:

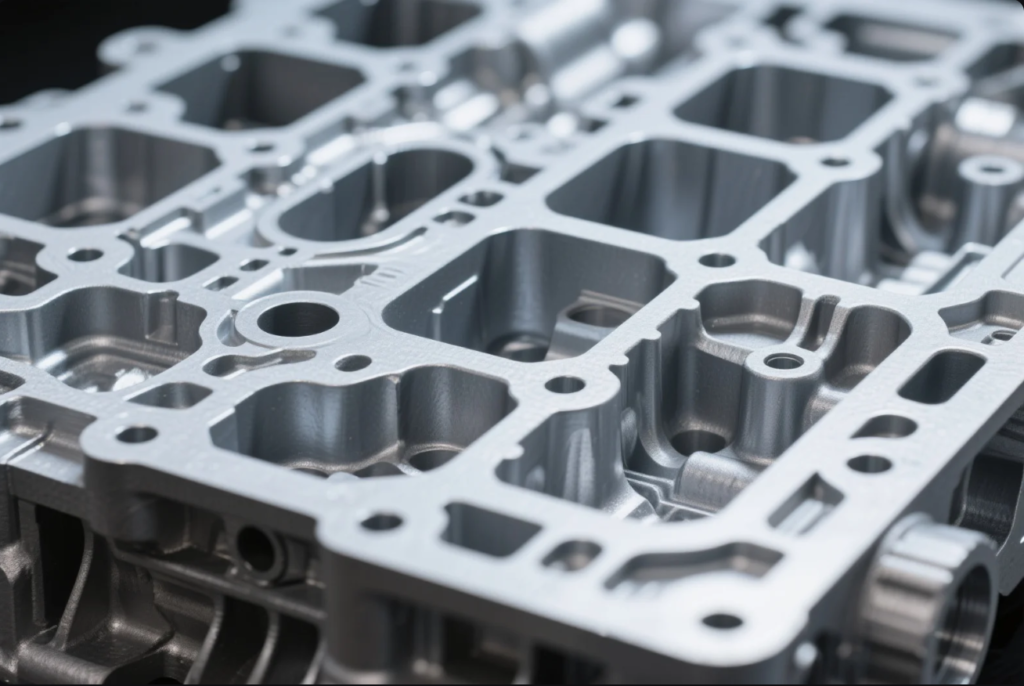

- Engine blocks and cylinder heads

- Gear housings and transmission cases

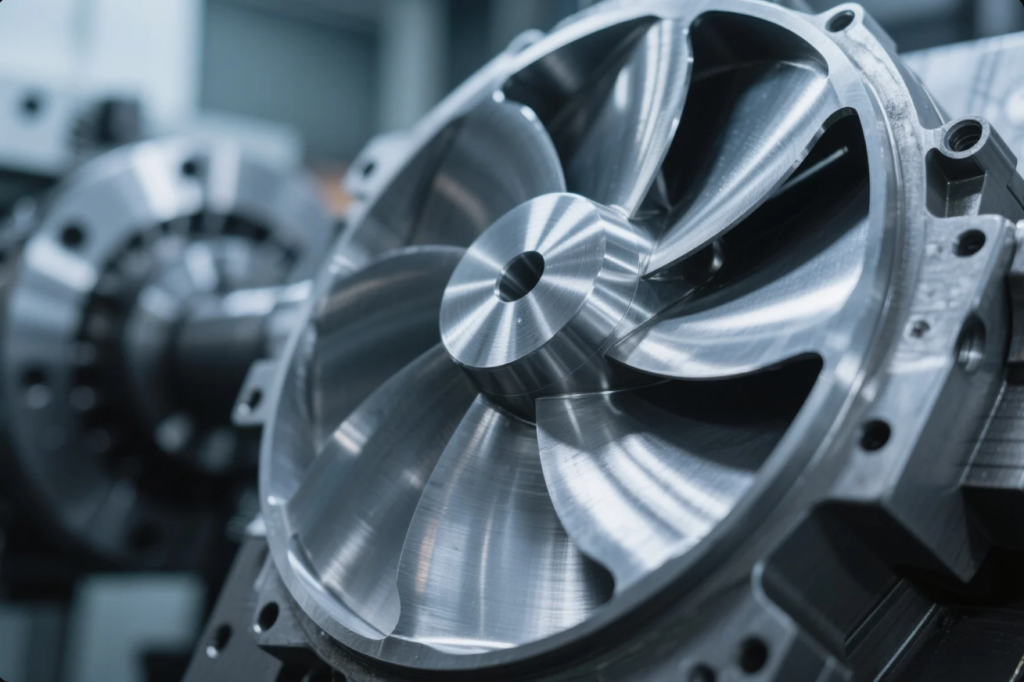

- Aerospace turbine blades

- Surgical tools and orthopedic implants

- Cookware and decorative ironwork

- Heavy equipment frames and valve bodies

Casting accommodates complex geometries, internal cavities, and varied wall thickness.

Which is an example of casting?

A classic example is an engine block created via sand casting. It includes internal coolant channels and precise machining references.

Another is an aluminum casing for electric vehicle gearboxes, made by pressure die casting. These parts need strength and dimensional accuracy.

What is the most popular process of metal casting called?

Sand casting is the most used process. It works for nearly all metals, handles large and small parts, and has low tooling costs.

Other popular processes include:

- Die casting for high volumes and tight tolerances

- Investment casting for fine details and high surface quality

- Lost-foam casting for seamless cavities without cores

Each has strengths depending on material, size, complexity, and production volume.

Top 10 Custom Metal Casting Manufacturers in 2025

These global manufacturers deliver precision cast parts with certifications and strong engineering:

- Prime Precision Castings – Full-service foundry in China with ISO certifications, in-house machining, global export service

- Grob GmbH (Germany) – Aerospace-grade castings with machining and surface finishing

- Ogihara Corporation (Japan) – Specializes in magnesium/aluminum automotive and aerospace die cast parts

- Mercury Power Products (USA) – Marine-grade aluminum pressure die castings

- Nikko Castings (India) – High-quality lost-wax investment cast parts for turbines and medical equipment

- Shandong Foundry Equipment (China) – Specializing in ductile and gray iron, with surface coatings and export packaging

- Pema Group (Sweden) – Cast iron and steel components for heavy industry

- Indo-MIM (Indonesia) – Volume zinc/aluminum die castings for electronics

- DieTech Castings (Mexico) – Automotive-grade die and sand castings

- Scaw Metals (South Africa) – Supplier of gray iron parts for the mining and construction sectors

What makes a supplier ideal for precision metal casting?

Top casting suppliers provide:

- Tolerance: ±0.1 mm or better after machining

- Advanced tooling and core systems

- Material range: iron, steel, aluminum, bronze, superalloys

- Heat treatments: annealing, quenching, aging

- In-house CNC machining and finishing

- Certifications: ISO 9001, AS9100, ISO 13485, PED/CE

- Quality checks: FAI, NDT (UT/PT/MT), SPC, dimensional reports

- Real-time monitoring and full traceability

- Engineering support: CAD optimization, casting simulation

- Environmental programs: closed-loop recycling, low-emission furnaces

Best practices when sourcing metal cast parts

To ensure quality and reliability:

- Submit clear 3D models (STEP/IGES) with tolerance zones

- Provide environment data: load, temperature, corrosion, wear

- Ask for DFC review and simulation analysis

- Test pilot runs and validate NDT results

- Include complete machining and assembly drawings

- Plan logistics for heavy or oversize shipments

- Verify certifications, quality data, and factory inspections

- Use supplier with backup tooling, long-term mold storage

- Request case studies in similar industries

These steps prevent costly redesigns or missed delivery deadlines.

FAQs

Q: Which casting process gives the best surface finish?

A: Investment casting offers fine finishes and accurate detailing.

Q: Can I request bronze or Inconel parts?

A: Yes. Most suppliers support specialty alloys for demanding conditions.

Q: Is die casting only for high volumes?

A: Typically yes, but some support low-volume with soft tools.

Q: How long does it take to get cast parts?

A: Tooling + samples = 6–10 weeks. Production = 12–20 weeks.

Q: Are foundries eco-compliant?

A: Reputable ones use emission controls, recycle scrap, and follow ISO 14001.

Conclusion

Casting continues to power critical industries. Gray iron and aluminum dominate in sand, die, and investment casting formats. The best suppliers combine metallurgy, machining, inspection, and global logistics. Follow best practices to source durable, cost-effective precision components.

👉 Start your custom casting project with Prime Precision Castings – contact us at [email protected] or visit primeprecision.com for expert support and a free