Top Injection Molding Companies for Custom Plastic Parts in 2025

📌 Table of Contents

- What Are the Most Reliable Injection Molders in the Market?

- Key Capabilities of Leading Plastic Molding Factories

- How Injection Molding Delivers High Precision at Scale

- Tips for Sourcing Plastic Molded Parts from Asia and Beyond

- Top Injection Molding Companies in 2025

- FAQs About Injection Molding Services

- Conclusion: Choosing the Right Injection Molding Partner

- Contact Us

Top Injection Molding Companies for Custom Plastic Parts in 2025

Injection molding remains the preferred solution for producing high-volume plastic parts with consistent quality and low per-unit cost. In 2025, industries like automotive, medical, electronics, and industrial machinery are increasingly demanding reliable and scalable injection molding partners.

This guide identifies top-rated injection molding companies, explains key factory capabilities, and provides sourcing insights for global buyers.

What Are the Most Reliable Injection Molders in the Market?

A reliable injection molding supplier will exhibit:

- ✅ ISO certifications (e.g., ISO 9001, IATF 16949, ISO 13485)

- ✅ Full-service capabilities: from mold design to secondary assembly

- ✅ Material traceability and resin expertise

- ✅ Tooling precision and preventive maintenance systems

- ✅ Support for tight tolerances and complex geometries

📌 Prime Example:

Prime Custom Parts is a China-based factory with over 20 years of OEM experience, offering high-volume injection molding for global clients across automotive, electrical, and consumer industries.

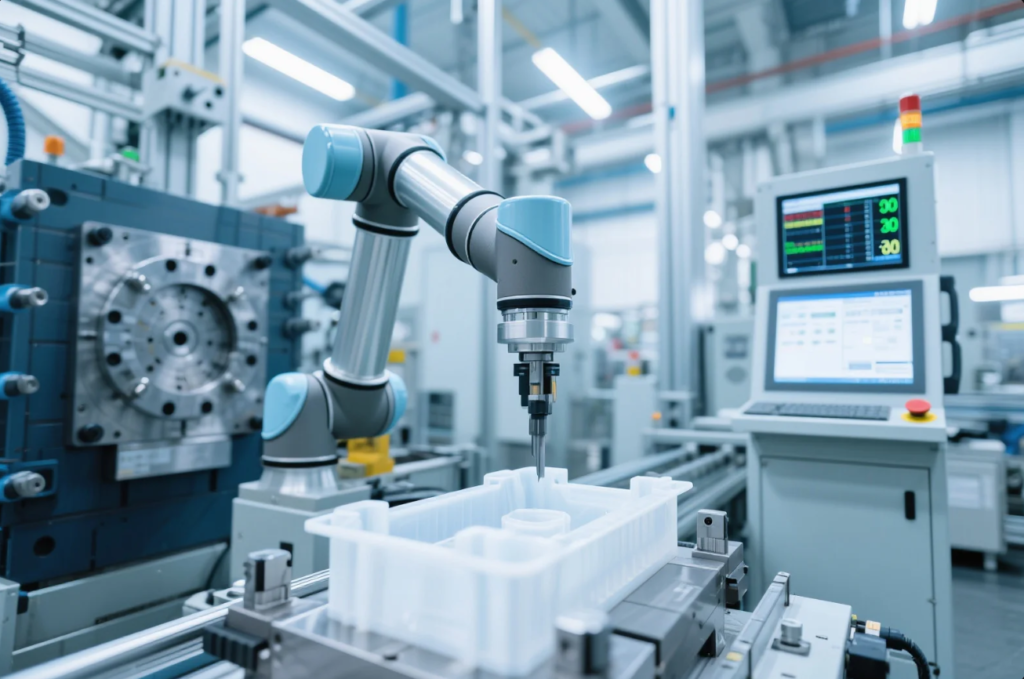

Key Capabilities of Leading Plastic Molding Factories

Leading injection molding companies typically offer:

- In-house Mold Making: Reduces lead time and improves design precision

- Cleanroom Molding: Essential for medical and optical parts

- Overmolding and Insert Molding: Combining plastic with metal or electronics

- Automated Assembly Lines: Ensures efficiency and scalability

- Material Expertise: Including ABS, POM, PC, Nylon, PEEK, and bioplastics

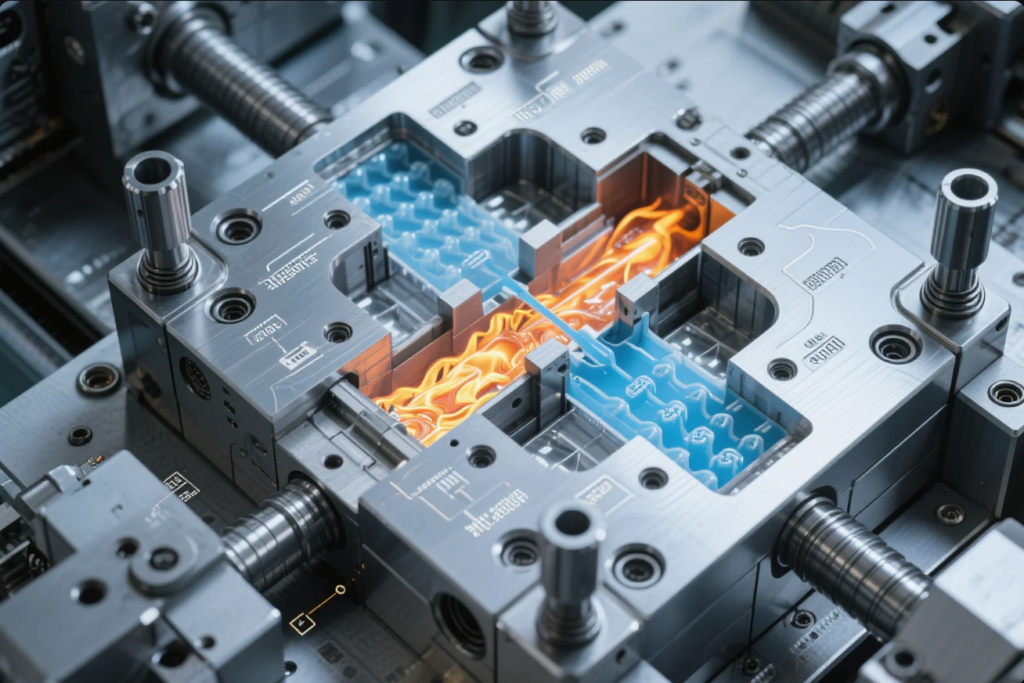

How Injection Molding Delivers High Precision at Scale

Injection molding achieves precision through:

- 🔧 Tightly machined steel molds with tolerances as low as ±0.01mm

- 🔄 Consistent cycle times and automated monitoring for part repeatability

- 📉 Low cost per part once tooling is amortized

- 🌱 Minimal waste through efficient gating and regrind processes

This makes injection molding ideal for producing millions of identical parts for critical applications—especially in automotive connectors, electronics housings, and medical enclosures.

Tips for Sourcing Plastic Molded Parts from Asia and Beyond

When sourcing from global suppliers (especially in China, Vietnam, or India), consider the following:

- Tooling Ownership: Ensure you retain the rights to your mold

- MOQ Flexibility: Some factories support small batches for prototyping

- Shipping & Tariffs: Factor in duties and lead times

- Factory Audit or Video Inspection: Always confirm capabilities

- Language & Engineering Communication: Crucial for custom part projects

📌 Tip: Prime Custom Parts offers multilingual sales engineers, rapid mold development, and end-to-end export support for North America, Europe, and the Middle East.

Top Injection Molding Companies in 2025

| Company Name | Headquarters | Website | Capabilities |

|---|---|---|---|

| Protolabs | USA | prototyping, low-volume rapid molding | |

| EVCO Plastics | USA/China | full-scale production, multi-materials | |

| Plastikon Industries | USA | medical and electronics molding | |

| Rosti Group | Sweden/Asia | global tooling + injection + assembly | |

| Prime Custom Parts | China | OEM/ODM molding, overmolding, insert tooling | |

| Mold-Masters | Canada | advanced hot runner systems | |

| Technoplast India | India | industrial parts, ODM consumer plastics | |

| Stack Plastics | USA | aerospace and high-precision molding | |

| Tessy Plastics | USA | medical-grade cleanroom production | |

| MGS Manufacturing | USA/Mexico | integrated tooling + automation systems |

FAQs About Injection Molding Services

Q1: How much does custom injection molding cost?

Tooling can range from \$3,000–\$50,000+ depending on size and complexity. Unit prices may fall below \$0.10 for high-volume parts.

Q2: What is the typical lead time for molded plastic parts?

Standard mold-making takes 3–6 weeks, with initial samples available within 10–15 days. Production parts follow in 1–3 weeks.

Q3: Which materials are best for injection molding?

Common choices include ABS, Polypropylene, Nylon, PEEK, and PC. Medical parts may use USP Class VI materials.

Q4: Can injection molding support hybrid plastic-metal components?

Yes—through insert molding, overmolding, and ultrasonic welding, suppliers like Prime Custom Parts deliver high-strength hybrid assemblies.

Q5: Do I own the mold after production?

Ownership depends on the contract. Ensure your agreement clearly states mold ownership, especially with offshore suppliers.

Conclusion: Choosing the Right Injection Molding Partner

The best injection molding companies in 2025 offer more than just machines—they provide design feedback, tight-tolerance precision, logistics support, and certified quality systems.

Whether you need high-speed runs of consumer parts or surgical-grade medical housings, working with a supplier like Prime Custom Parts ensures reliability, transparency, and competitive pricing.

Contact Us

📧 Need help with your injection molding project? Reach out to our engineering team today.

- 🌐 Website: https://primecustomparts.com

- 📩 Email: [email protected]

Meta SEO

Meta Title:

Top Injection Molding Companies 2025 | Best Custom Plastic Part Manufacturers

Meta Description:

Explore the best injection molding suppliers in 2025 for custom plastic parts. Discover global leaders, sourcing tips, and key factory capabilities. Request a quote today.