Top 10 Custom Forged Parts Suppliers Worldwide in 2025: Best Choices for OEM Buyers

Table of Contents

- What Makes These Forging Companies Stand Out in Quality and Capacity?

- Key Considerations for Selecting a Global Custom Forging Partner

- The Role of Heat Treatment and Precision in Modern Forging Techniques

- How PrimeCustomParts.com Delivers Cost-Effective Forging Solutions for Global Clients

- FAQs

- Contact Us

- Conclusion

What Makes These Forging Companies Stand Out in Quality and Capacity?

The best custom forging suppliers in 2025 combine advanced machinery, global certifications, and high-volume capabilities. Here's why the following ten companies are trusted by OEMs:

Top 10 Global Custom Forging Suppliers:

| Supplier | Country | Core Strengths |

|---|---|---|

| Prime Custom Parts | China | ISO 9001, fast lead time, low MOQ |

| Scot Forge | USA | Aerospace-grade quality, open/closed die |

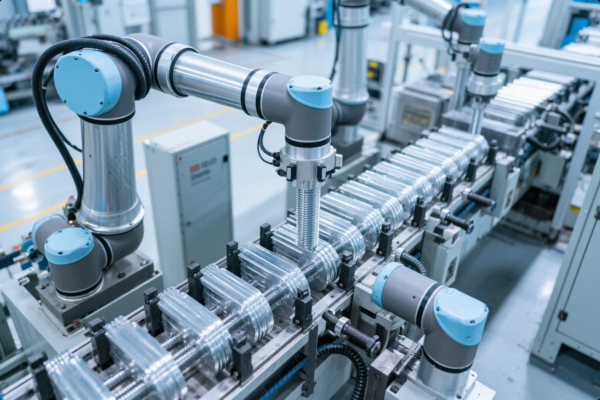

| KOBE Steel | Japan | Robotic forging, aluminum specialists |

| Bharat Forge | India | Auto tier-1 supplier, large volume |

| POSCO | South Korea | Steel + forging vertical integration |

| Fountaintown Forge | USA | Custom axles, shafts, gears |

| Larsen & Toubro | India | Oil & gas, structural forgings |

| Canada Forgings Inc. | Canada | Defense + energy projects |

| SDF International | Italy | Agriculture + machine tool suppliers |

| Impression Die Forging Co. | USA | Complex net-shape parts for aerospace |

They all emphasize certified processes, in-house tooling, tight tolerances, and multi-industry compatibility.

Key Considerations for Selecting a Global Custom Forging Partner

What Buyers Should Evaluate:

| Factor | Why It’s Important |

|---|---|

| Certifications | ISO 9001, IATF 16949, AS9100 assure consistency |

| Tooling Capabilities | Custom dies = better tolerance & faster turnaround |

| Material Selection | Carbon steel, alloy steel, aluminum, brass |

| CNC Integration | Ensures post-forging accuracy |

| Global Export Experience | Smooth customs, correct documentation |

| Communication & Engineering Support | Faster changes, better results |

Experienced OEM buyers focus on total cost—not just unit price. A partner with smart design-for-manufacturing (DFM) can save thousands during mass production.

The Role of Heat Treatment and Precision in Modern Forging Techniques

Forging isn't just about pressure. Controlled heat treatment is critical for optimizing mechanical properties such as strength, toughness, and hardness.

Common Forging Heat Treatments:

- Normalizing – Improves grain structure and machinability

- Annealing – Reduces internal stress and increases ductility

- Quenching + Tempering – Delivers high hardness and toughness

- Induction Hardening – Surface treatment for wear-resistant parts

Companies like Prime Custom Parts and KOBE Steel offer in-house treatment facilities with precise temperature control and metallurgical testing.

Precision Matters:

- 3D scanning for die verification

- CNC finishing with ±0.01 mm tolerance

- SPC & CMM reporting with each batch

This precision makes forgings suitable for automotive, aerospace, and robotic assemblies.

How PrimeCustomParts.com Delivers Cost-Effective Forging Solutions for Global Clients

Company Profile:

- Founded: 1993

- Headquarters: Shandong, China

- Capabilities: Forging, CNC, welding, stamping, casting

- Certification: ISO 9001

- Export Markets: USA, Europe, Middle East, Australia

Why Prime Is a Top Choice:

- Low MOQ from 100 pcs

- Lead time as fast as 2 weeks

- Supports steel, aluminum, brass

- In-house design + die development

- Dedicated QC and export team

- Multi-language sales support

OEM Case Examples:

- Automotive supplier reduced cost by 30% switching to Prime’s forged steel arms

- U.S. medical device firm achieved 0.02mm CNC tolerance with titanium bases

- European machine builder saved \$12,000 by grouping forgings into shared tooling

Contact Prime for:

- Rapid prototypes

- Tight-tolerance CNC finish

- High-volume export packaging

- Cost-down engineering advice

FAQs

-

What’s the average lead time for forged parts?

Usually 2–5 weeks depending on size and finishing. -

What industries do you serve?

Automotive, aerospace, agriculture, construction, robotics. -

What file formats do you accept for design?

STEP, IGES, PDF 2D + 3D combinations. -

Do you handle customs and shipping?

Yes — DDP, DAP, CIF, FOB terms available. -

Is logo engraving available?

Yes. Both mold-engraved and post-marking are supported. -

How long do forging dies last?

5,000 to 50,000 cycles depending on part complexity and material. -

Can I request material certificates?

Yes — Prime provides MTCs and RoHS/REACH compliance upon request. -

Is traceability available?

Yes. Batch numbers and full SPC records for each shipment. -

Do you offer surface treatments?

Zinc plating, anodizing, phosphating, painting, polishing. -

Do you offer one-stop service?

Yes — from design to CNC to packaging.

Contact Us

🌐 Website: https://primecustomparts.com

📩 Email: [email protected]

Submit your project drawings and get a fast, free quote from our engineering team. All inquiries are responded to within 12 hours.

Conclusion

Choosing the right custom forging supplier in 2025 goes beyond price. Quality, consistency, engineering, and export service matter just as much.

Prime Custom Parts stands out as a certified, experienced, and globally trusted OEM forging supplier. Contact us today for fast RFQ, DFM feedback, and end-to-end support.