Leading Custom Forging Manufacturers for Industrial Parts in 2025: A Global Comparison

Table of Contents

- How Do Global Forging Leaders Ensure Consistent Quality at Scale?

- Top USA, Germany, and China Forging Companies Ranked for 2025

- Key Materials Used in Custom Forging: From Carbon Steel to Inconel

- Why More B2B Buyers Are Switching to Multi-Axis Precision Forging Suppliers

- FAQs

- Contact Us

- Conclusion

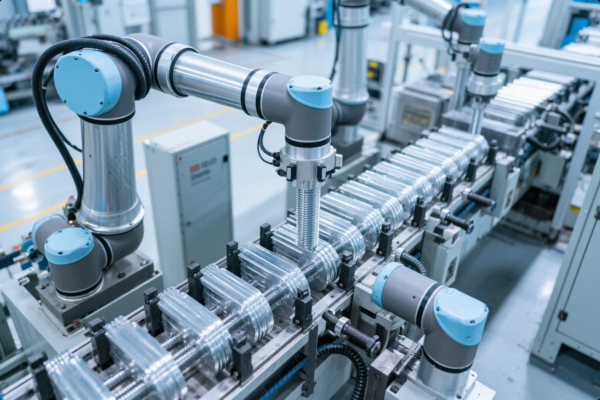

How Do Global Forging Leaders Ensure Consistent Quality at Scale?

In 2025, industrial buyers expect zero-defect tolerances and scalable output. Leading forging manufacturers have invested in automation, real-time quality monitoring, and digital traceability.

Common Quality Control Practices:

- CMM Inspection: Measures tight tolerances ±0.01 mm

- SPC Data Systems: Tracks part consistency in batches

- Forging Simulation Software: Predicts material flow and defect risks

- Heat Treatment Control: Monitors exact phase transitions

Companies like Prime Custom Parts and Scot Forge integrate full NDT testing, metallurgical labs, and batch-level serialization.

Top USA, Germany, and China Forging Companies Ranked for 2025

Global supply chain challenges have shifted focus to regional leaders who can scale and adapt quickly.

Top Companies by Region:

| Region | Company | Highlights |

|---|---|---|

| USA | Scot Forge | ISO/IATF, large-scale closed/open die |

| USA | Impression Die Forging | Complex shapes, aerospace, automotive |

| Germany | Otto Fuchs | Aerospace-grade aluminum & titanium |

| Germany | FRIEDR. LOHMANN GmbH | Inconel, stainless, specialty parts |

| China | Prime Custom Parts | ISO certified, full-service, fast lead time |

| China | Sinotruck Forging Division | Heavy truck + axle forgings |

Why they stand out:

- Vertically integrated metal supply

- Dedicated CAD + tooling workshops

- Flexible MOQ and multi-process support

- Documented compliance with ISO 9001 / IATF 16949

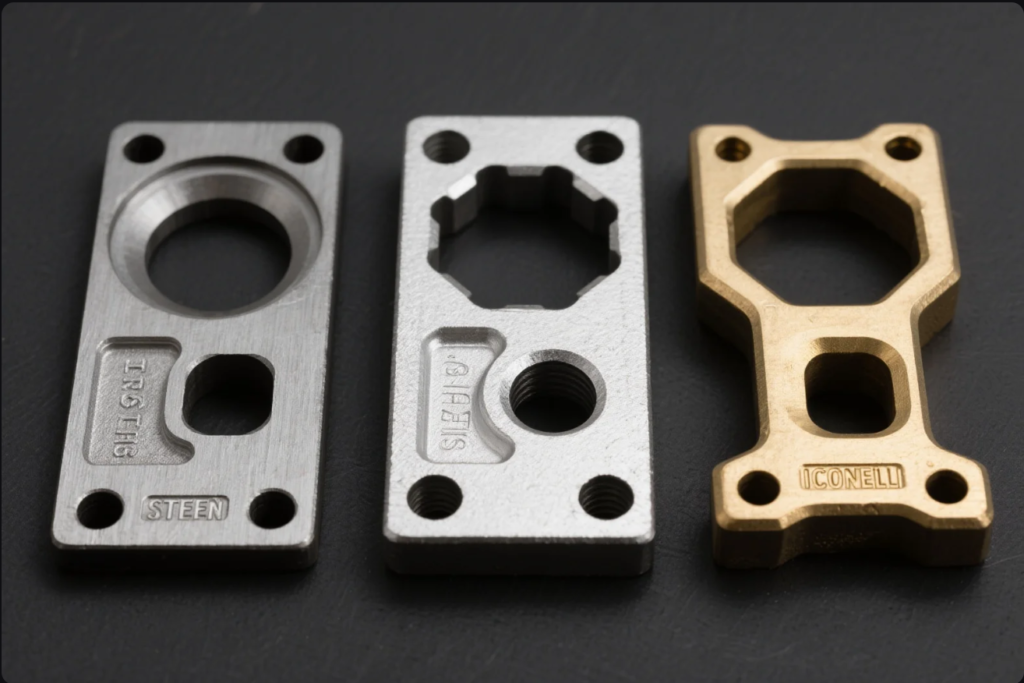

Key Materials Used in Custom Forging: From Carbon Steel to Inconel

Material selection in industrial forging affects performance, machining, cost, and corrosion resistance.

Common Materials Used:

| Material | Applications | Properties |

|---|---|---|

| Carbon Steel | Structural parts, automotive arms | Strong, cost-effective |

| Alloy Steel | High load parts, shafts | Heat treatable, wear-resistant |

| Aluminum | Lightweight brackets, aerospace | Corrosion-resistant, easy to machine |

| Brass/Bronze | Decorative, plumbing, bushings | Anti-friction, aesthetic finish |

| Stainless Steel | Food processing, valves | Anti-corrosion, tough |

| Inconel | Aerospace, turbines | High temp, high strength |

Prime Custom Parts supports forging in 42CrMo, 6061-T6, AISI 4140, 316L, and Inconel 718, with full material certificates.

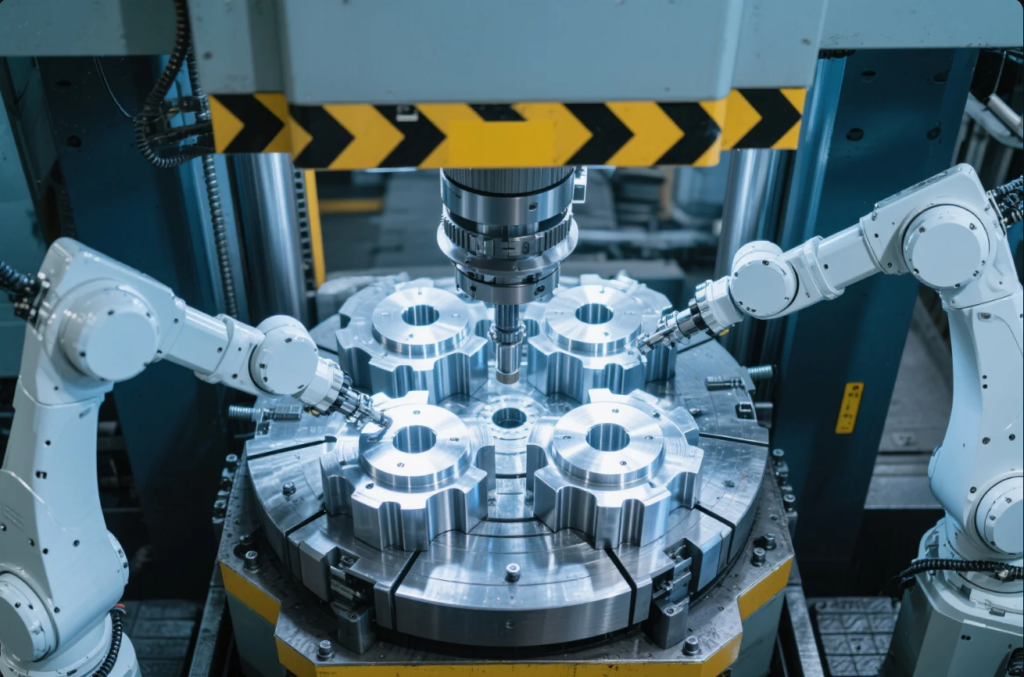

Why More B2B Buyers Are Switching to Multi-Axis Precision Forging Suppliers

High-performance parts today demand complex geometries with minimal machining. Multi-axis precision forging reduces waste, cost, and lead time.

Key Benefits of Precision Forging:

- Near-net shapes = Less CNC finishing

- Improved mechanical properties due to fiber flow alignment

- High dimensional accuracy without warping

- Consistent surface finish

KOBE Steel and Prime Custom Parts use 3-axis to 5-axis hydraulic presses and integrated CNC to deliver complex flanges, turbine blades, valve bodies, and robotic joints.

FAQs

-

What’s the MOQ for industrial forged parts?

100–300 pcs, depending on material and process. -

Which industries do you support?

Automotive, aerospace, machinery, construction, energy, defense. -

Do you provide DFM support?

Yes, most top suppliers provide free CAD optimization before mold making. -

Are parts certified?

Yes — ISO 9001, IATF 16949, and material test reports are standard. -

Is surface treatment offered?

Yes: zinc plating, anodizing, passivation, phosphating, painting. -

Can I order by blanket purchase?

Yes, long-term pricing with scheduled releases available. -

Are forgings traceable?

Yes. Most companies offer lot numbers, barcodes, and QR code tags. -

Do you offer express tooling?

Prime offers 5–7 day express die manufacturing service.

Contact Us

🌐 Website: https://primecustomparts.com

📩 Email: [email protected]

Submit drawings or RFQs today. Our engineers respond within 12 hours with quotes, DFM feedback, and shipment plans. Trusted by global OEMs.

Conclusion

Forged parts remain essential in industries demanding strength, accuracy, and volume. In 2025, the best global suppliers combine certified systems, smart tooling, and multi-axis integration.

Prime Custom Parts delivers all this—plus fast lead time, competitive pricing, and proven global service. Get in touch now to build a better forging partnership.