Best Aluminum Threaded Component Suppliers for OEM Projects

Table of Contents

- Which Industries Rely Most on Threaded Aluminum Parts?

- Key Quality Certifications Required for OEM Applications

- Comparing Lead Times and MOQ Among Global Suppliers

- Why OEM Buyers Choose PrimeCustomParts.com for Custom Aluminum Parts

- FAQs

- Contact Us

- Conclusion

Which Industries Rely Most on Threaded Aluminum Parts?

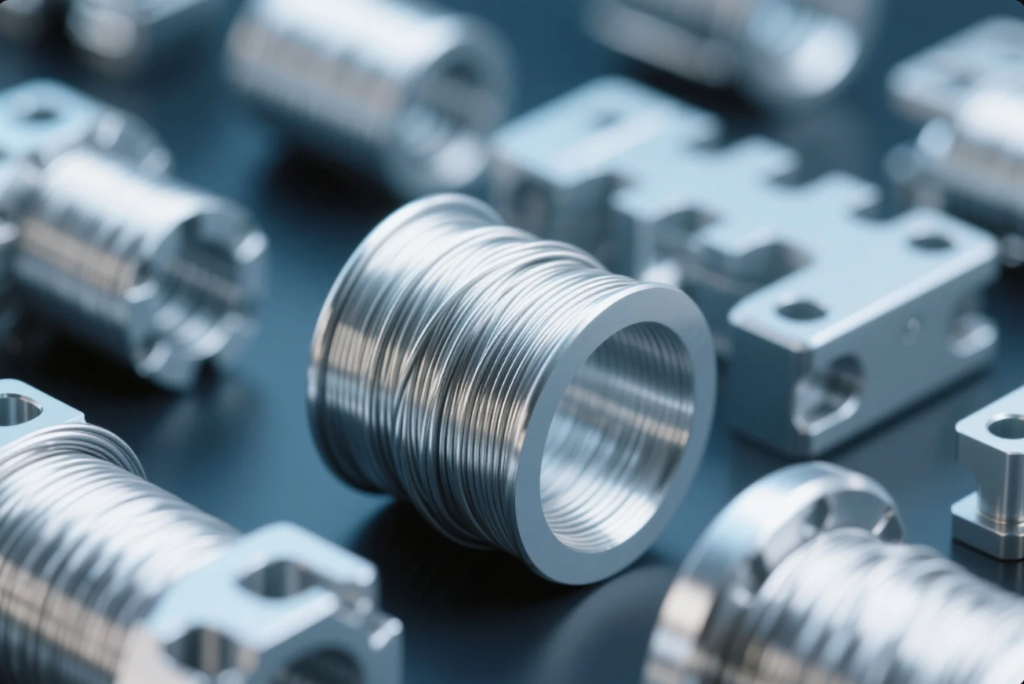

Threaded aluminum parts are lightweight, corrosion-resistant, and easy to finish. In 2025, demand has expanded beyond traditional applications.

Top Industries Using Threaded Aluminum:

| Industry | Parts Used | Purpose |

|---|---|---|

| Aerospace | Inserts, bushings, housing bolts | Lightweight + vibration resistance |

| Electronics | Threaded enclosures, heat sink fasteners | Thermal conductivity + machinability |

| Automotive | Engine brackets, mounts, battery connectors | Weight-saving + strength |

| Medical | Implant housings, tool handles | Biocompatibility + corrosion protection |

| Renewable Energy | Solar frame connectors, EV battery terminals | Outdoor durability + conductivity |

Aluminum alloy types like 6061, 7075, and 5052 are favored for their combination of machinability and performance under stress.

Key Quality Certifications Required for OEM Applications

OEM buyers need assurance that parts meet consistent specs, lot after lot. Certifications ensure control, traceability, and reliability.

Required Certifications:

| Certification | Required For | What It Covers |

|---|---|---|

| ISO 9001 | All industrial buyers | Quality system, process control |

| IATF 16949 | Automotive OEMs | Automotive-specific production |

| AS9100 | Aerospace & defense | Risk-based thinking + airworthiness |

| RoHS/REACH | Electronics & medical | Environmental & material compliance |

| PPAP | Production parts approval | Dimensional + material validation |

Companies like Prime Custom Parts and Fastenal Manufacturing include full certification packages and lot traceability with every OEM order.

Comparing Lead Times and MOQ Among Global Suppliers

Choosing the right aluminum threading supplier depends on speed, flexibility, and price. Here's how top 2025 vendors compare:

| Supplier | Region | MOQ | Lead Time | Specialization |

|---|---|---|---|---|

| Prime Custom Parts | China | 100 pcs | 7–15 days | Small batch, custom threading |

| Protolabs | USA | 1–50 pcs | 3–7 days | Fast prototyping |

| Fictiv | USA | 100 pcs | 10–20 days | Online DFM + sourcing |

| XY Machining | China | 200 pcs | 10–18 days | Consumer electronics focus |

| Jingxin Precision | China | 300 pcs | 10–21 days | Connector-grade fasteners |

PrimeCustomParts.com strikes a balance between low MOQ, moderate speed, and full OEM service including packaging and labeling.

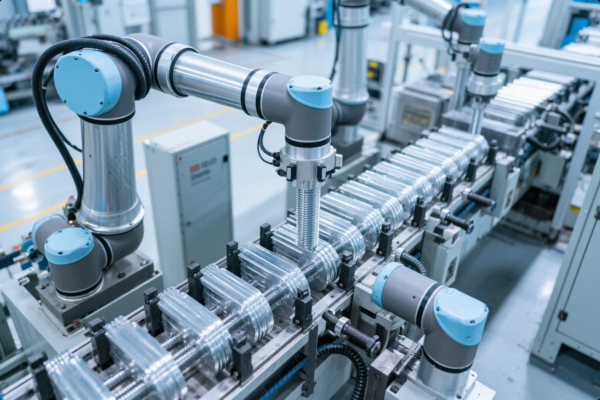

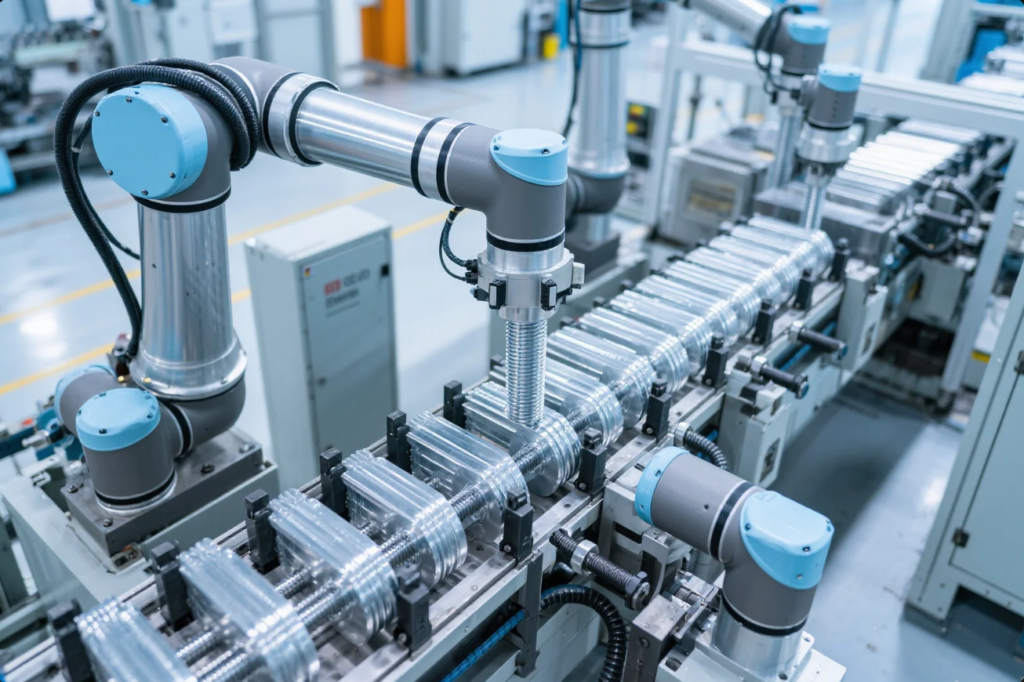

Why OEM Buyers Choose PrimeCustomParts.com for Custom Aluminum Parts

Overview:

- 10 in-house lines: CNC, forging, stamping, anodizing

- ISO 9001 certified; IATF available upon request

- Custom anodized colors + salt spray testing

- Services: 2D/3D design, DFM, PPAP, COC, barcode packaging

What OEMs Like About Prime:

- Rapid sampling: 5–7 day tooling

- Micron-level tolerance for threads: ±0.01 mm

- Surface options: matte, bright, satin anodizing

- Branding support: laser logo, QR code ID

- Bilingual engineering support + 24h RFQ reply

OEM clients in Germany, the U.S., and Saudi Arabia have praised Prime for quick communication, stable quality, and affordable cost—especially for threaded enclosures and connectors.

FAQs

-

What’s the lead time for small aluminum fasteners?

7–12 days including anodizing. -

Can you do both internal and external threads?

Yes, CNC turning supports both. -

Is thread inspection done in-line?

Yes, GO/NOGO gauges and video systems are used. -

Do you support Type III hard anodizing?

Yes — for high-wear applications. -

What CAD formats are supported?

STEP, IGES, DWG, PDF, STL. -

Do you include a certificate of compliance (COC)?

Yes — with batch numbers and inspector signature. -

Can I request color-matched parts for branding?

Yes — color anodizing options available.

Contact Us

🌐 Website: https://primecustomparts.com

📩 Email: [email protected]

Send your aluminum part drawings now. Get quotes in 12 hours, samples in 7 days, and full-scale production in 2 weeks. Global shipping available.

Conclusion

Threaded aluminum parts require more than cutting a thread—they demand material knowledge, surface finishing, inspection, and fast delivery.

Prime Custom Parts delivers this with certified systems and OEM-minded service. Start your next aluminum component project with confidence—request your quote now.