Top-Rated CNC Aluminum Threaded Part Makers Globally in 2025

Table of Contents

- The Role of CNC Machining in High-Precision Threaded Parts

- What to Look for in a CNC Threading Partner

- Case Studies: Aerospace and Automotive Applications

- How PrimeCustomParts.com Ensures ISO-Certified Threading Processes

- FAQs

- Contact Us

- Conclusion

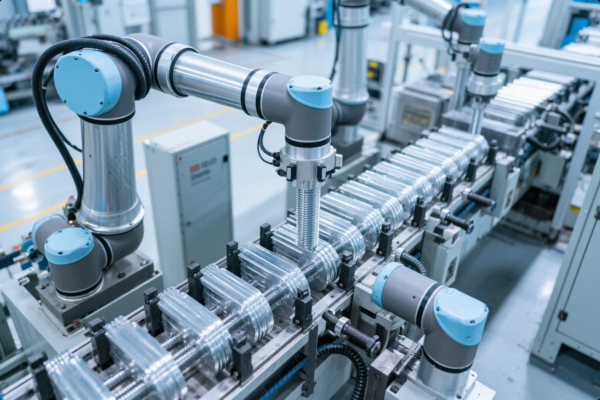

The Role of CNC Machining in High-Precision Threaded Parts

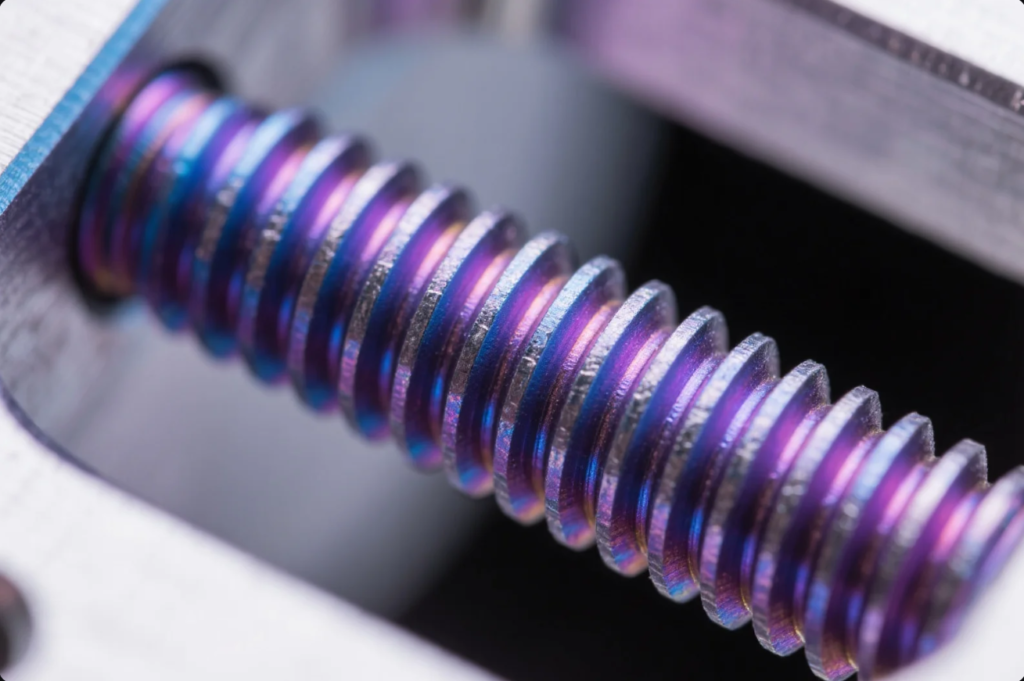

CNC machining is essential for aluminum threading due to its consistency, toolpath precision, and ability to machine both internal and external threads with minimal deformation.

Advantages:

- Repeatability: Every part meets ±0.01 mm tolerance

- Versatility: Supports UNC, UNF, Metric, ACME, and custom threads

- Integrated processes: Machining + deburring + anodizing in one cycle

- Speed: High-speed turning with automatic tool changers

- Surface integrity: No burrs, galling, or thread collapse

In 2025, OEM buyers prioritize CNC over manual or die threading for complex assemblies and long-term consistency.

What to Look for in a CNC Threading Partner

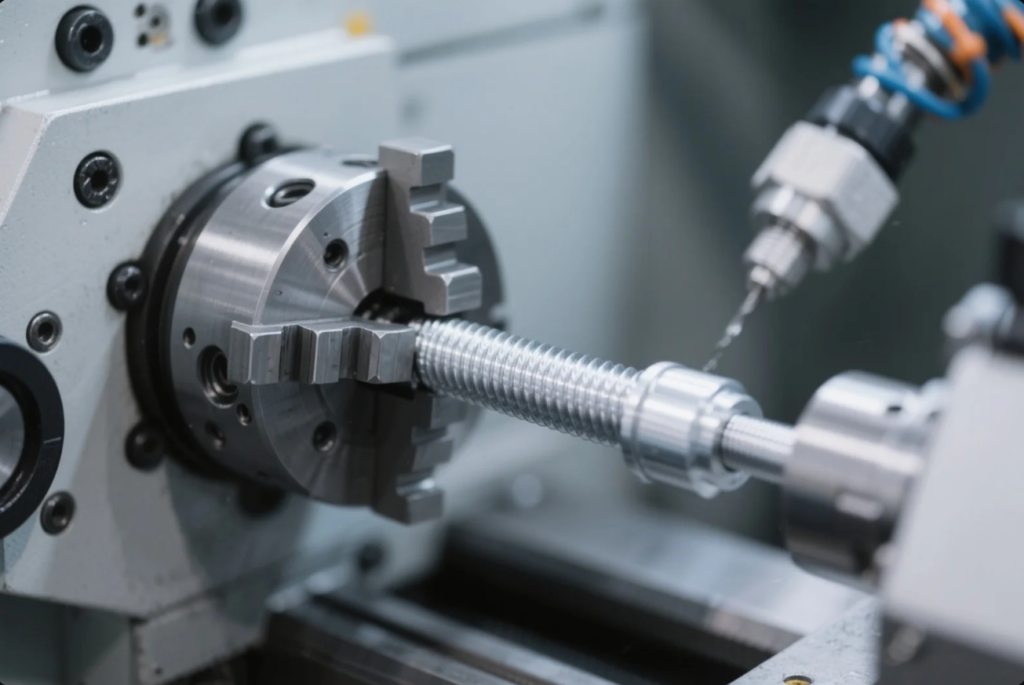

Threading in aluminum requires more than a lathe. It demands design review, toolpath simulation, and in-process verification.

Partner Selection Checklist:

| Criteria | What to Check | Why It Matters |

|---|---|---|

| Certifications | ISO 9001 / IATF 16949 | Assures process control |

| Threading Range | M1–M36, UNC/UNF | Covers all common specs |

| Tool Life Monitoring | Auto offset detection | Reduces out-of-spec threads |

| Microscope Verification | Edge clarity check | Ensures consistent mating performance |

| Batch Reports | CMM + Thread Gauge | Required for PPAP or traceability |

Top partners like Prime Custom Parts use Swiss lathes, live-tooling, and bar feeders to streamline both prototyping and mass production.

Case Studies: Aerospace and Automotive Applications

Aerospace Case (Germany):

- Client: Tier-1 avionics supplier

- Part: 7075-T6 threaded mounting flanges

- Requirements: ±0.01 mm tolerance, Type III anodizing, GO/NOGO verified

- Results: 0.6% rejection rate over 5,000 pcs

- Why CNC: Prevented thread collapse on thin walls, reduced weight

Automotive Case (USA):

- Client: EV drivetrain integrator

- Part: 6061 aluminum threaded cooling blocks

- Specs: Internal M12 x 1.25, anodized, high flow

- Results: 12% part cost reduction, 21% tooling cost saved

- Why CNC: Fast iteration + repeatability across 10K/month run

In both cases, thread integrity and dimensional repeatability were the top concerns—and CNC solved them at scale.

How PrimeCustomParts.com Ensures ISO-Certified Threading Processes

Company Snapshot:

- Founded: 1993

- Country: China

- Capabilities: CNC, forging, stamping, anodizing

- Certifications: ISO 9001, RoHS, full PPAP, COC

- Global Clients: USA, Germany, UAE, Australia

Key Threading Advantages:

- Swiss CNC lathes + auto bar feeders

- Thread range: UNC 4-40 to M36

- External & internal threads on same setup

- Inline GO/NOGO + off-line CMM testing

- Anodizing + laser logo post-process in-house

OEM Client Feedback:

- “Prime’s threads passed our 50,000-cycle wear test” – German auto OEM

- “They gave us 12-hour DFM feedback + color-matched anodizing” – U.S. tech firm

- “We got full reports + QR code tags with every pallet” – Saudi robotics distributor

FAQs

-

What’s your max thread size?

M36 external; M20 internal with CNC single-point control. -

Do you offer multi-start threads?

Yes — for special connectors or locking nuts. -

Can you do reverse thread direction?

Yes — left-hand and right-hand threads supported. -

Do you check threads on 100% of parts?

Yes — optical camera for large runs, manual GO/NOGO for low volume. -

Do you export with thread protection caps?

Yes — foam caps or plastic threaded covers provided. -

Can I get both threaded aluminum + steel in same shipment?

Yes — mixed metal orders consolidated.

Contact Us

🌐 Website: https://primecustomparts.com

📩 Email: [email protected]

Get in touch for your next CNC aluminum threading project. We deliver ISO quality, short lead times, and global B2B support.

Conclusion

In 2025, OEMs need aluminum threads that perform under stress—accurate, consistent, corrosion-resistant, and ready to assemble.

Prime Custom Parts delivers certified CNC precision, scalable capacity, and unbeatable lead times. Request your quote today and partner with a global threading expert.