Top 10 Metal Surface Finishing Companies in 2025 for Industrial‑Grade Quality?

Table of Contents

- What Is Metal Surface Finishing and Why Is It Crucial?

- Key Types: Electroplating, Powder Coating, and Anodizing Explained

- How to Choose a Surface Finishing Company Based on Your Industry Needs

- Certifications and Standards That Top Surface Finishers Must Meet

- Top 10 Surface Finishing Companies in 2025

- How Surface Finishing Impacts Global Supply Chains

- Frequently Asked Questions (FAQs)

- Conclusion & Prime Contact Info

What Is Metal Surface Finishing and Why Is It Crucial?

Metal surface finishing improves durability, appearance, and performance of metal parts. As Wikipedia explains, it includes various methods like electroplating, powder coating, and anodizing to achieve better functionality and aesthetics.

Without surface finishing:

- Corrosion shortens part life

- Wear increases maintenance costs

- Poor finishes fail inspection or customer expectations

- Adhesion issues arise during painting

Key Types: Electroplating, Powder Coating, and Anodizing Explained

Electroplating

- Applies metal layers like zinc, nickel, or chrome

- Ideal for small parts and precision areas

- Inexpensive, conductive, corrosion-resistant

Powder Coating

- Applies dry powder via static charge, then cures at high heat

- Offers tough, decorative coating for large items

- Solvent-free, long-lasting

Anodizing

- For aluminum, builds oxide layer via electrochemical treatment

- Enhances wear, corrosion resistance, and dye adhesion

- Common in aerospace and electronics

How to Choose a Surface Finishing Company Based on Your Industry Needs

Each industry has unique requirements. A surface finisher must match your product type, standards, and delivery expectations.

Key Considerations:

- Do they serve your industry (e.g., automotive, electronics)?

- Can they meet lead time and quality consistency?

- Do they provide RoHS or REACH certificates?

- Are they flexible with MOQs and sample support?

| Industry | Finish Required | Key Feature |

|---|---|---|

| Automotive | Zinc & Powder Coating | Salt spray test >500 hours |

| Aerospace | Anodizing | Traceability, IATF 16949 |

| Electronics | Nickel/Gold Plating | Thin layers, RoHS compliant |

| Construction | Powder Coating | UV/weather resistant |

| Machinery | Chromate + Zinc | Durable, wear-proof |

Certifications and Standards That Top Surface Finishers Must Meet

Certifications guarantee quality and global compliance.

Important Standards:

- ISO 9001 – Quality Management

- ISO 14001 – Environmental Controls

- IATF 16949 – Automotive Industry

- RoHS/REACH – Chemical Safety

- NADCAP – Aerospace Process Certification

Ask suppliers for:

- PDF certificates with registrar name

- Valid expiry dates

- Lab reports for RoHS or salt spray

- Internal audit and CAPA logs

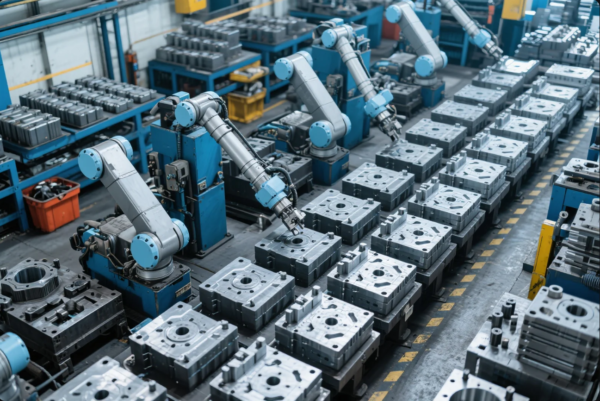

Top 10 Surface Finishing Companies in 2025

These global leaders stand out based on certifications, automation, and customer satisfaction:

- PPG Coatings Services (USA)

- Henkel Surface Technologies (Germany)

- Chemtech Industries (India)

- Prime Surface Finishing (China)

- MacDermid Enthone (UK/USA)

- Alcoa Surface Treatments (USA)

- Dongjin Semichem (South Korea)

- KTL Powder Coating (Sweden)

- SurTec Group (Germany)

- Tech-Metall (Poland)

Why Prime ranks high:

- 10 finishing lines: electroplating, CNC, anodizing

- 20+ years B2B experience

- ISO 9001, RoHS, IATF 16949 certified

- Fast delivery: 15–25 days

- Excellent packaging and export readiness

How Surface Finishing Impacts Global Supply Chains

Surface finishing affects lead time, product approval, and logistics costs. Delays at this stage can disrupt the entire project schedule.

- Delayed plating can hold up export

- Inadequate packing leads to damage

- Missing RoHS reports blocks EU customs

- Inconsistent finish quality results in rework

Smart buyer tips:

- Prioritize suppliers with 95%+ on-time rates

- Use XRF reports to verify coating compliance

- Always ask for a first-article inspection before mass production

Frequently Asked Questions (FAQs)

Q1: What is typical zinc coating thickness?

A: 8–12μm; for marine parts ≥15μm with chromate.

Q2: Can aluminum be powder coated?

A: Yes, but it needs pre-treatment and curing.

Q3: How fast is the anodizing process?

A: 30–45 min per cycle, plus drying.

Q4: How to ensure corrosion-free shipping?

A: Use VCI packaging, desiccants, and sealed plastic bags.

Q5: Does Prime support RoHS/REACH?

A: Yes, with third-party test reports on request.

Q6: What is Prime’s minimum order?

A: Flexible MOQ—ideal for both small and large batches.

Q7: Can I get a sample?

A: Yes, Prime provides free samples and pre-production test runs.

Conclusion & Prime Contact Info

Choosing a certified surface finishing partner ensures your products meet global standards, reduce failure risk, and arrive on time. Prime Surface Finishing delivers all that—and more.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Contact Prime now for a free consultation, detailed quote, and global delivery assurance. Let our expertise keep your components protected and your projects on schedule.