Best Metal Finishing Processes for Corrosion Resistance and Aesthetic Appeal?

Table of Contents

- Introduction: Why Metal Surface Treatment Matters?

- Which Surface Treatment Offers the Highest Corrosion Protection?

- Aesthetic vs Functional Finishes: What’s the Right Balance?

- Case Study: Surface Treatment Solutions for Automotive & Aerospace

- How to Extend Product Lifespan Through Advanced Surface Technologies

- FAQs

- Conclusion & Contact

Introduction: Why Metal Surface Treatment Matters?

I often faced rust issues in my sourcing. It caused delays and extra cost. I felt frustrated by poor finishes. But I found solutions, and so can you.

Surface treatment improves corrosion resistance and aesthetics. Good finishing not only protects metal from harsh environments but also enhances product appearance. This article helps engineers, procurement teams, and decision-makers choose top finishing methods. You’ll learn how to pick the right process, compare costs and performance, and apply these insights directly.

Read on to gain practical knowledge, technical depth, and real case evidence. You'll end with a clear call to action.

Which Surface Treatment Offers the Highest Corrosion Protection?

Facing rust issues? You lose money and time. You need strong protection now.

Snippet

Different finishing methods offer varied levels of corrosion defense.

Zinc plating, powder coating, and anodizing are top contenders.

Each suits specific metals and environments.

You get detailed pros, cons, and real-world uses.

Overview of Top Coatings

-

- Electrochemical deposition of zinc on steel.

- Provides anti-rust barrier; meets ASTM B633 standards.

-

- Applies polymer powder cured by heat.

- Thick, durable, chip-resistant finish.

-

- Electrochemical oxide layer for aluminum.

- Increases hardness, wear resistance, and aesthetic options thanks to dyability.

Dive-Deeper Table

| Finish Type | Metals | Protection Level | Thickness | Ideal For |

|---|---|---|---|---|

| Zinc Plating | Steel | High (≥200 h salt) | 5–25 µm | Industrial parts |

| Powder Coating | Steel, Aluminum | Very High (≥500 h) | 50–150 µm | Outdoor equipment, panels |

| Anodizing | Aluminum only | High (sealed oxide) | 10–25 µm | Aerospace, architecture |

Why choose powder coating:

It creates both barrier and seal, ideal for outdoor or marine use.

Why choose anodizing:

For aluminum parts, it delivers durable, wear-resistant surface with color choices.

Aesthetic vs Functional Finishes: What’s the Right Balance?

You want parts that look great yet perform. Pure function is dull; pure aesthetics may rust. Let’s balance both.

Snippet

Aesthetic finishes: powder coating, decorative plating, painting.

Functional finishes: zinc, anodizing, phosphate, passivation.

You can combine them to boost both form and function.

Trusted Finish Combinations

-

Anodize + Clear Coat

- For aluminum. Adds shine and abrasion resistance.

- Medium cost. Common in aerospace.

-

Zinc + Powder Coat

- For steel. Provides barrier and color together.

- Medium–high cost. Good for chassis, outdoor parts.

-

Nickel + Chrome Plating

- Mirror-like finish. Highly reflective.

- High cost. Common in decorative hardware.

-

Zn‑Ni + Trivalent Chromate

- Steel parts with salt spray resistance.

- Light appearance, medium–high cost. Good for electronics enclosures.

| Combination | Visual Quality | Use Case | Cost |

|---|---|---|---|

| Anodize + Clear Coat | Gloss or matte | Aerospace parts | Medium |

| Zinc + Powder Coat | Solid color | Outdoor machinery | Medium–High |

| Nickel + Chrome Plating | High mirror finish | Trim, decorative parts | High |

| Zn‑Ni + Chromate | Light color finish | Enclosures, fasteners | Medium–High |

Choose combos based on environment, durability needs, and budget.

Case Study: Surface Treatment Solutions for Automotive & Aerospace

Customer faced corrosion in aerospace parts. They failed salt spray tests. We offered custom solutions.

Snippet

Prime processed aluminum hubs and steel fasteners.

We applied anodizing, PTFE sealing, and zinc‑nickel plating.

After treatment, parts passed >1000 h salt spray.

They met tolerance and improved field use.

Dive Deeper

Project Overview

- Parts: Aluminum wheel hubs & steel screws

- Goal: ≥1000 h salt spray; tolerance within ±0.02 mm

- Challenge: Manage mixed-metal surfaces; adhere to tight specs

Treatment Workflow

- CNC-machine parts for precision.

- Anodize aluminum hubs at \~15 µm.

- Seal with PTFE for abrasion resistance.

- Zinc‑nickel plate steel fasteners to 12–18 µm.

- Inspect and pack using export-standard packaging.

Results

| Metric | Before | After |

|---|---|---|

| Salt Spray Resistance | \~200 h | ≥1000 h |

| Tolerance | \~±0.02 mm | Maintained |

| Hardness (Al hubs) | 60 HV | \~150 HV |

| Abrasion Resistance | Low | High |

Customer Feedback:

After 12 months, no corrosion. Clients praised our fast communication and delivery. They now rely on Prime as a trusted supplier.

How to Extend Product Lifespan Through Advanced Surface Technologies

Frequent parts replacement drains budgets. Standard coatings lack durability. Invest in advanced coatings.

Snippet

Duplex systems and nano-ceramic finishes extend lifespan.

They layer base and top for synergy.

That reduces maintenance and replacement costs.

Advanced Surface Technologies

Duplex Coatings

Combine zinc or zinc-nickel base with powder coat.

| System | Base Layer | Top Layer | Results |

|---|---|---|---|

| Zn + Epoxy Powder | 8–12 µm Zn | 60–120 µm powder | 1000 h salt resistance, add color |

| Zn‑Ni + Polyester | 12–18 µm Zn‑Ni | 50–100 µm polyester | 1500 h resistance |

Great for heavy machinery, marine hardware, outdoor components.

Nano-Ceramic Finishes

Polymer embed with nano-ceramic particles:

| Trait | Nano‑Ceramic | Traditional Powder |

|---|---|---|

| Hardness Increase | +30–50 HV | +10–20 HV |

| Scratch Resistance | High | Medium |

| Cost | High | Medium |

Ideal for tools, wear components, valves.

PTFE‑Sealed Hard Anodize

Aluminum sealed in PTFE:

- Ultra low friction

- Ideal for sliding metal surfaces

- Great for bearings, moulds, gears

FAQs

Q1: Which coating suits marine use best?

Duplex systems (Zn‑Ni + powder) hold up to 1500 h in salt spray tests. Great for maritime environments.

Q2: Can anodizing be used for metals except aluminum?

No. Anodizing works only with aluminum alloys.

Q3: How thick is nano‑ceramic coating?

Typically ranges 30–60 µm. Thickness depends on layer build-up method.

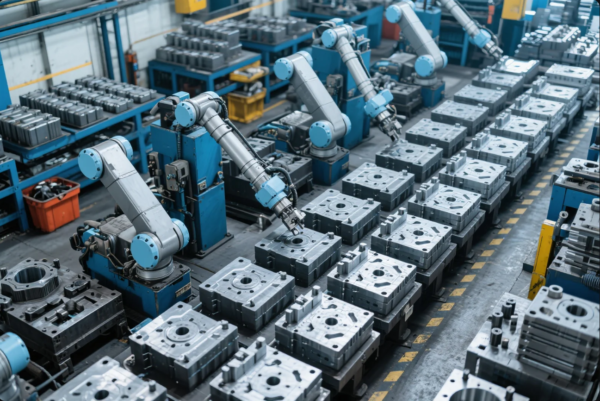

Q4: Does Prime handle complex precision parts?

Absolutely. We have ISO 9001/14001-certified CNC lines and maintain ±0.02 mm accuracy.

Q5: What’s the lead time for surface-treated parts?

Standard: 15–25 days; expedited service: 10–15 days, depending on order volume.

Q6: Do you provide export safety packaging for treated parts?

Yes. We use foam padding, sealed bags, wooden or metal crates meeting global shipping norms.

Conclusion & Contact

Choose duplex or nano-ceramic coatings to significantly extend lifespan.

Select finishing combo based on material, usage environment, and budget.

The right treatment saves money, improves product durability, and boosts brand image.

Get Expert Help from Prime

Contact Prime to optimize your surface finishing needs:

- ✅ Free professional consultation

- ✅ Tailored quotes and custom solutions

- ✅ ISO-certified quality and stable, fast delivery

📞 Visit: primecustomparts.com

📧 Email: [email protected]

Let Prime supply high-quality, precisely finished parts — delivered on time and built to last.