2025’s Most Cost-Effective Metal Finishing Methods for OEM Manufacturers?

Table of Contents

- What Are the Most Affordable Finishing Options Without Compromising Quality?

- Bulk Finishing Services: When and How to Reduce Costs at Scale

- Comparing In‑House vs Outsourced Surface Finishing Solutions

- How OEMs Can Meet ISO Requirements Through Proper Surface Treatments

- FAQs

- Conclusion & Contact

What Are the Most Affordable Finishing Options Without Compromising Quality?

I once bought plated parts on price alone. They failed quickly. I lost trust in low-cost suppliers. Then I started choosing methods that save money and last longer.

Affordable doesn’t mean low-quality.

In 2025, these finishes offer strong protection at low cost:

- Zinc/Electrogalvanizing: Steel gets 5–25 µm zinc. Affordable and reliable.

- Powder Coating: Thick, durable, and cost-effective for large batches.

- Passivation: For stainless steel; involves no plating, just chemical cleaning.

- Phosphating: A cheap prepaint method that improves adhesion and corrosion protection.

Dive Deeper

Zinc Plating/Electrogalvanizing

- Costs are low per part, especially for large batches.

- Salt spray resistance \~200–500 hours.

- Ideal for components like fasteners and frames.

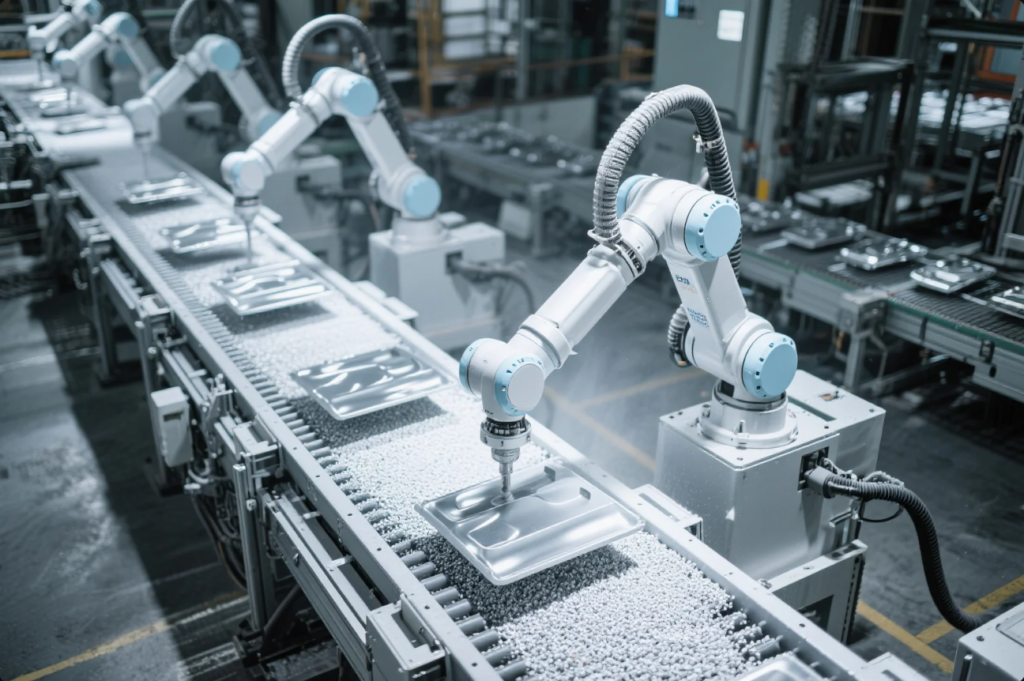

Powder Coating

- Costs scale well with volume.

- Offers UV and impact resistance.

- Can add value with custom colors and branding.

Passivation (Stainless Steel)

- No metal added or removed.

- Removes free iron to improve corrosion resistance.

- Simple bath process, low cost, good ISO compliance.

Phosphating (Steel Pre‑coat)

- Cheap chemical conversion coating.

- Adds texture and adhesion for paint.

- Not decorative, but functional at minimal cost.

Bulk Finishing Services: When and How to Reduce Costs at Scale

I learned that large orders cut per-part cost dramatically. Negotiating bulk finish deals saved me 30% overall.

Economies of scale drive value.

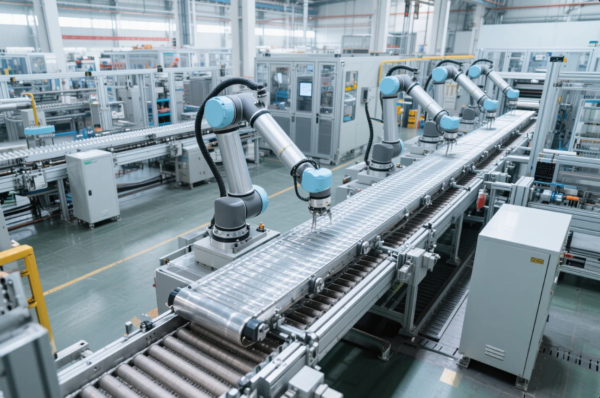

Large batch runs, automated lines, and efficient logistics can transform costing.

Bulk Finishing Strategies

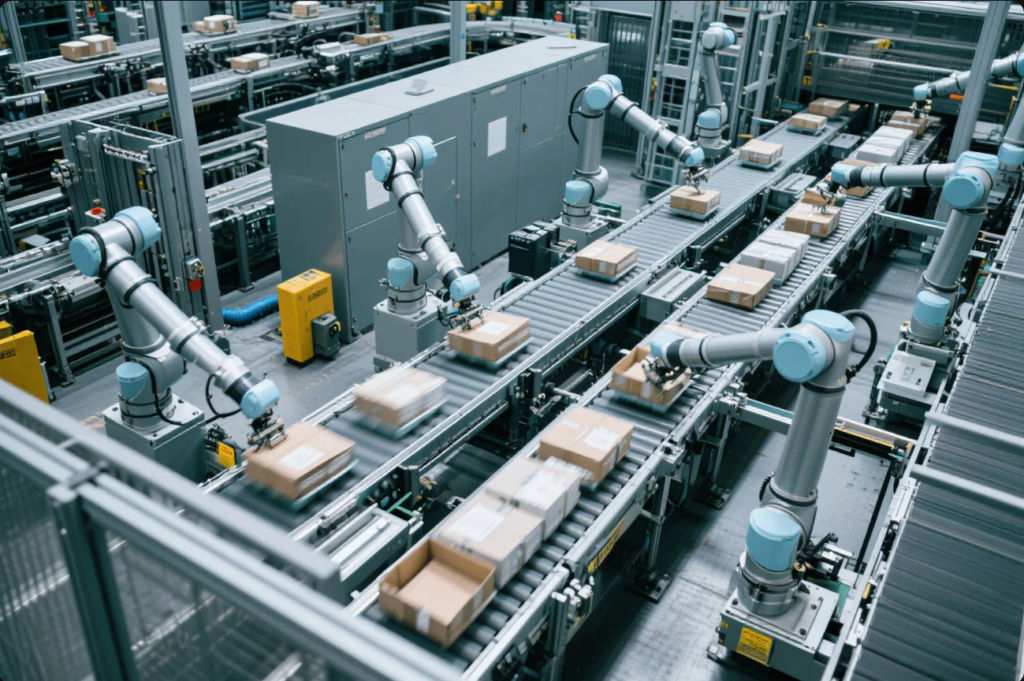

- Batch Scheduling: Group similar parts for one finish run.

- Volume Discounts: Suppliers drop unit cost above a threshold.

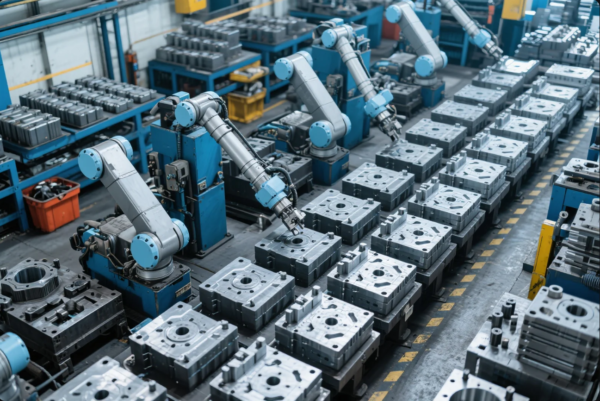

- Automated Lines: Conveyorized powder or plating systems offer efficiency.

- Local Co‑packing: Combine finishing and packaging under one roof.

Example Table

| Batch Size | Zinc Plating Cost/Part | Powder Coat Cost/Part | Passivation Cost/Part |

|---|---|---|---|

| 100 pcs | \$3.50 | \$4.00 | \$1.00 |

| 1,000 pcs | \$1.20 | \$1.80 | \$0.75 |

| 10,000 pcs | \$0.60 | \$1.10 | \$0.50 |

Savings come from setup amortization, minimized rework, and streamlined logistics.

Comparing In‑House vs Outsourced Surface Finishing Solutions

I considered investing in my own plating line. My team built it—but maintenance and compliance costs added up.

In-house gives control, outsourced gives flexibility.

Which is right for OEMs in 2025?

In‑House Finishing

-

Pros:

- Full control over process and schedule.

- Faster changeovers.

- IP safety and integration with internal QC.

-

Cons:

- High upfront capex.

- Staffing, licensure, and environmental permits required.

- Lower volume spreads cost poorly.

Outsourced Finishing

-

Pros:

- Low initial cost.

- Specialists offer process variety and certifications.

- Location independence and scale pricing.

-

Cons:

- Lead times tied to supplier schedule.

- Inconsistent timing if batch size varies.

- Quality oversight is needed via audits.

Decision Table

| Factor | In‑House | Outsourced |

|---|---|---|

| Initial Cost | High | Low |

| Running Cost | Medium–High | Low–Medium |

| Volume Sync | Needs demand forecast | Flexible volume acceptance |

| Quality Control | Direct control | Audits & inspections |

| Compliance | Complex | Supplier handles it |

| Tech Flexibility | Limited once set | Access to latest tech |

For most OEMs, starting outsourced and adding modest in-house capacity strikes a good balance.

How OEMs Can Meet ISO Requirements Through Proper Surface Treatments

I asked my supplier for ISO-certified plating. They sent manual test reports. I had doubts.

ISO compliance matters—especially for OEMs in regulated industries.

Methods include:

- ISO 9001 for quality systems.

- ISO 14001 for environmental management.

- ISO/IEC 17025 for test labs, e.g., salt-spray, coating thickness.

- RoHS / REACH / EPA compliance for chemicals used.

Key ISO Actions

- Supplier Selection: Require certificates and lab data.

- Coating Metrics: Salt spray ≥500 h; roughness Ra ≤0.8 µm.

- Change Control: Track process changes and outcomes.

- Documentation: Batch logs, part IDs, process sheets.

Example: Passivation for Stainless Parts

By following ISO 9001 and using in-house or reputable passivation houses certified per ASTM A967, OEMs protect medical or food-processing components and track each batch.

FAQs

Q: Is powder coating cheaper than painting?

Yes—no solvents, faster cure, minimal waste.

Q: What’s cheapest for functional corrosion protection?

Zinc plating or passivation both cost under \$2/part in volume.

Q: Can finishing help OEMs hit RoHS or REACH?

Yes—using compliant plating solutions and documented processes ensures ICO/S.

Q: Do I need ISO 14001 for finishing?

If you handle chemicals and plating, yes—especially for permit and waste tracking.

Q: How to verify outsourced surface quality?

Audit lab certifications, request test results, inspect per lot, build trust.

Conclusion & Contact

Cost-effective doesn’t mean low-quality. Zinc plating, powder coating, passivation, and phosphating all deliver value when chosen well. Bulk finishing and proper planning reduce costs. Balancing in-house control with outsourced flexibility helps OEMs scale. Robust ISO compliance ensures trust and performance.

Contact Prime for Expert OEM Finishing Solutions

We are an ISO-certified custom metal parts factory with 10 production lines.

We deliver fast lead times, stable quality, and flexible finishing services.

📞 Visit: https://primecustomparts.com/

📧 Email: [email protected]

Let’s work together to make high-quality, cost-effective, ISO-compliant parts.