Anodizing, Plating, and Coating: Which Metal Surface Finish Is Best for Your Project?

Table of Contents

- Understanding the Pros and Cons of Each Finishing Method

- What to Ask Your Supplier Before Choosing a Surface Treatment

- Popular Surface Finishing Choices by Industry: Medical, Marine, Electronics

- PrimeCustomParts.com’s Capabilities in Custom Surface Finishing Services

- FAQs

- Conclusion & Contact

Understanding the Pros and Cons of Each Finishing Method

As I started sourcing parts, I noticed wide quality variation from different finishes. I learned to compare anodizing, plating, and coating to protect projects, budgets, and brand reputation.

Anodizing boosts wear resistance and aesthetics for aluminum. Plating offers corrosion protection and conductivity control. Coating delivers thick barriers and color finishes. Each method brings trade‑offs in cost, thickness, durability, and visual quality.

Anodizing Pros & Cons

- Hard oxide layer adds wear resistance; can be dyed for aesthetics

- More eco-friendly than hexavalent chrome

- Limited only to aluminum with thickness around 10–25 μm

- Less protective than duplex coatings in marine environments

- Ideal for architectural components, electronics housings, and automotive trim

- More info on anodizing at en.wikipedia.org/wiki/Anodizing and environmental benefits via the Aluminum Anodizers Council website anodizing.org

Plating Pros & Cons

- Zinc plating protects steel and suits industrial parts; see details at en.wikipedia.org/wiki/Galvanization

- Zinc-nickel plating offers superior salt resistance (up to 1000+ hours), referenced by aerospace manufacturers

- Copper or tin plating supports electrical conductivity

- Requires strict process control; be aware of RoHS/REACH via European Commission documentation environment/waste/rohs_eee

- Nickel and chrome plating are used for decorative hardware; chrome plating info at chrome.org

Coating Pros & Cons

- Powder coating provides robust, color-stable layers (50–150 μm); learn about basics at ptonline.com/articles/the-basics-of-powder-coating

- Liquid coatings are easy to touch up and hide minor defects

- Ceramic or nano coatings offer ultra-hard surfaces ideal for tooling; technology information at cerakote.com/technology

- Requires ovens and curing; layer thickness can affect fit and alignment

What to Ask Your Supplier Before Choosing a Surface Treatment

When I first ordered finishes, vague promises cost me delays. Then I learned the right questions.

Ask these essential questions:

- What is the exact applied thickness (μm or mil)?

- Can you provide salt-spray and adhesion test reports per ASTM B117 (see astm.org/Standards/B117.htm)?

- Are you ISO 9001 and ISO 14001 certified? Certificates link at iso.org/iso-9001-quality-management.html

- What is the resulting surface roughness (Ra)?

- Are coatings RoHS, REACH, and EPA compliant? See EU's RoHS guidelines environment/waste/rohs_eee

- Do you record batch-level quality documentation and traceability?

- Can your finish meet tight tolerances like ±0.01 mm?

- How are parts packaged to prevent damage?

Providing these specs upfront ensures clarity and reduces costly surprises.

Popular Surface Finishing Choices by Industry: Medical, Marine, Electronics

Different industries impose unique demands. Choose finishes tailored to industry requirements and compliance.

Medical Device Industry

- Electropolished 316 stainless steel for Ra < 0.2 µm; meets ISO 13485

- PTFE-sealed aluminum anodizing minimizes friction and promotes sterilization

- Gold plating for electrical contacts; biocompatibility standards at fda.gov

- Traceable packaging and batch records essential for FDA device traceability

Marine & Offshore Industry

- Duplex coatings (Zn-Ni + powder) yield 1500+ h salt-spray resistance

- Hard anodizing or ceramic coatings are used for seawater-exposed fittings

- Phosphating + marine paint is low-cost but effective

- Packaging in moisture-barrier film with desiccant packs is critical

Electronics & Telecom Industry

- Thin zinc or nickel plating is standard for fasteners and EMI shielding

- ENIG plating meets IPC-4552 standards at ipc.org

- Aluminum anodized housing dyed for branding purposes

- Conductive coatings with carbon or silver for EMI/RFI; see ieee.org for EMI standards

PrimeCustomParts.com’s Capabilities in Custom Surface Finishing Services

At PrimeCustomParts.com, we provide robust finishing solutions designed for quality, compliance, and precision.

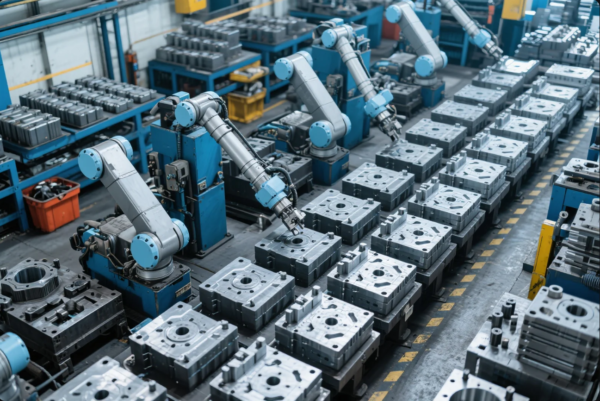

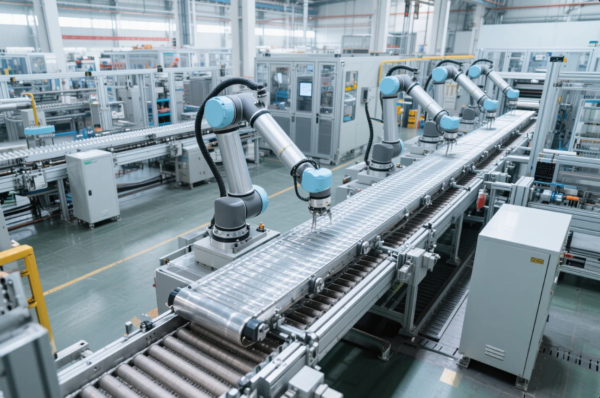

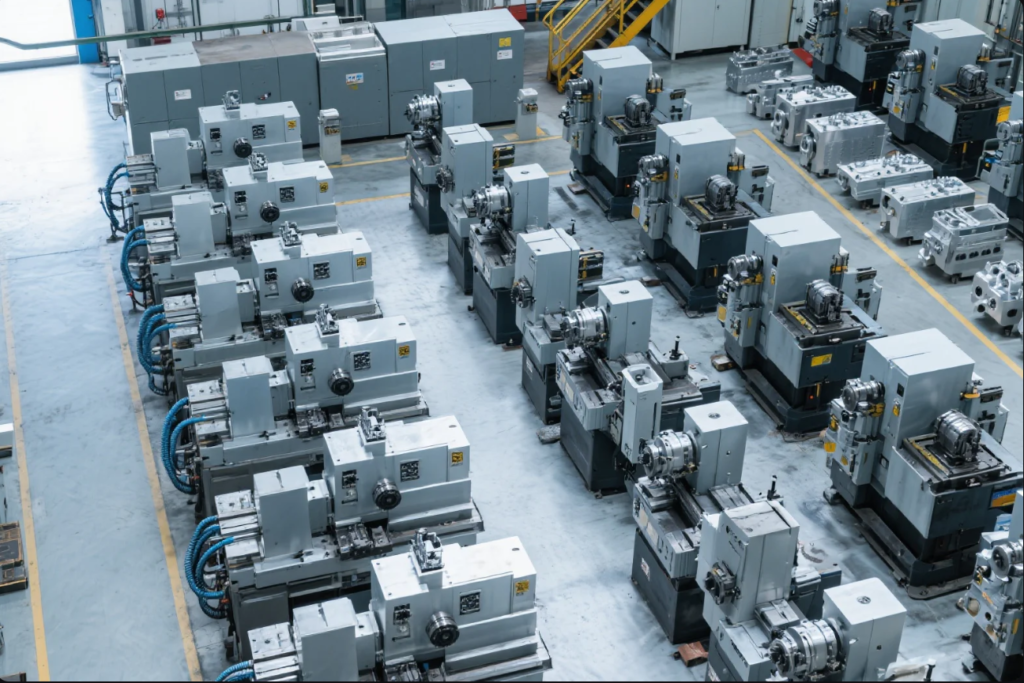

Finishing Infrastructure

- 10 production lines including anodizing, plating, powder coating, electropolishing

- ISO 9001 and ISO 14001 certified; certificates available at iso.org

- Bake ovens up to 1000 m³ for powder cure

- Inline thickness XRF measurement and salt-spray chambers

Supported Metals and Materials

- Aluminum alloys (6000, 7000 series)

- Carbon and stainless steels (300/400 series)

- Brass, copper, and other specialty alloys

Custom Finishing Options

- Hard and decorative anodizing in any RAL color

- Zinc, nickel, and copper plating with full RoHS/REACH compliance

- Powder and liquid coatings, including ceramic-infused options

- Electropolishing, chemical etching, and passivation services

Industry-Specific Services

We regularly serve medical, marine, electronics, and aerospace OEMs with:

- Tight tolerance parts to ±0.02 mm

- Salt-spray performances ≥1000 h

- Custom packaging to preserve sensitive finishes

Why OEMs Choose Us

- Over 20 years in OEM service

- Competitive pricing through batch optimization

- Fast delivery via integrated lines

- Full documentation including RoHS, REACH, traceability, and test data

FAQs

Q: Do you provide testing certifications with parts?

Yes. We supply salt-spray test reports and coating thickness records for every batch.

Q: Are your coatings RoHS and REACH compliant?

Yes. All chemicals and processes follow documentation standards at ec.europa.eu.

Q: Can you process multiple finishes in single batch runs?

Yes. We group similar finishes together to save cost and setup time.

Q: What is your typical lead time?

Surface finishing takes about 15–20 working days; we offer expedited service on request.

Q: Can you provide custom dye colors or markings?

We support RAL color choice, custom dyes, etching, and branding requests.

Q: How are parts packaged to safeguard finishes?

Parts are packed using anti-scratch foam, sealed film, desiccants, and export-rated crates with inspection photos.

Conclusion & Contact

Choosing the right finish (anodizing, plating, or coating) depends on metals, project specs, cost, and compliance needs. Asking the right questions and checking supplier capabilities helps avoid cost overruns and quality issues.

Schedule a Free Consultation

PrimeCustomParts.com is your trusted partner for high-quality custom metal finishing. With ten production lines, ISO compliance, and decades of OEM experience, we deliver fast, compliant, and value-driven solutions.

📞 Visit: https://primecustomparts.com/

📧 Email: [email protected]

Partner with us for performance-driven surface finishing that meets your project demands.