Best Materials for High-Performance Metal Stamping Parts in 2025?

I often face stamping failures caused by wrong material choices. I need clear guidance now.

This guide compares stainless steel, aluminum, copper, and brass for stamped parts. It reviews strength, ductility, cost, and tooling impacts. Each material’s pros, cons, and use cases are presented clearly.

Keep reading to discover how the right metal improves product life, tool wear, and production cost.

Table of Contents

- Choosing Between Stainless Steel, Aluminum, Copper, and Brass

- Mechanical Properties That Matter Most in Stamped Components

- How Material Selection Affects Tool Life and Cost

- Which Industries Use Which Metals for Stamped Part Production?

- FAQs

- Conclusion & Contact Information

Choosing Between Stainless Steel, Aluminum, Copper, and Brass?

| Metal | Pros | Cons | Common Uses |

|---|---|---|---|

| Stainless Steel | High strength, corrosion resistant | Heavy, harder to form | Outdoor, medical, kitchen tools |

| Aluminum | Lightweight, rust-proof, easy to shape | Less strong, alloy cost varies | Automotive, aerospace, electronics |

| Copper | Conductive, antimicrobial, easy to stamp | Soft, low wear strength | Electrical contacts, cooling systems |

| Brass | Decorative, corrosion-resistant, formable | Prone to dezincification in water | Plumbing, appliances, art panels |

- Stainless steel: Outokumpu Datasheet

- Aluminum: Matmatch 6061-T6

- Copper: Copper.org Material Specs

- Brass: Aviva Metals – Brass Alloys

Mechanical Properties That Matter Most in Stamped Components?

| Property | Stainless Steel 304 | Aluminum 6061‑T6 | Copper C110 | Brass C260 |

|---|---|---|---|---|

| Yield Strength (MPa) | 215–275 | 276 | \~70 | 200–250 |

| Tensile Strength | 505 | 310 | \~210 | 300–360 |

| Elongation (%) | 40–60 | 12–18 | 30–50 | 20–40 |

| Hardness (HV) | \~170 | \~95 | \~60 | 80–180 |

| Fatigue Strength | High | Medium | Low | Medium |

Stainless works for harsh loads. Aluminum cuts weight. Copper offers conductivity. Brass provides elegant formability.

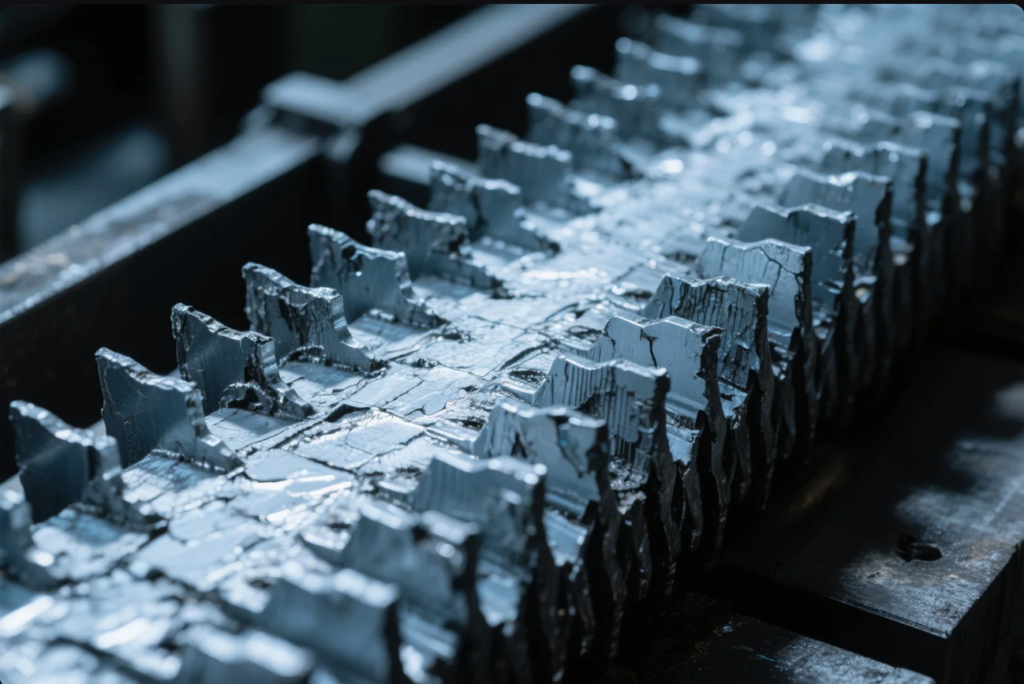

How Material Selection Affects Tool Life and Cost?

| Metal | Tool Wear Rate | Lubrication Needed | Sharpening Frequency | Downtime Cost |

|---|---|---|---|---|

| Stainless Steel | High | High | Every 10k–20k strokes | High |

| Aluminum | Medium | Medium | Every 30k+ strokes | Low |

| Copper | Low | Low | Rarely | Very Low |

| Brass | Medium | Low | Every 40k strokes | Low |

| Material | Avg Cost/kg (USD) | Notable Cost Drivers |

|---|---|---|

| Stainless Steel | \$1.50–2.50 | Alloy content, global demand |

| Aluminum 6061 | \$2.00–3.00 | Alloying, shipping, machining difficulty |

| Copper | \$9.50–11.60 | Electronics demand, purity |

| Brass | \$5.00–7.00 | Zinc content, polishing, finishes |

For details: Engineering Toolbox – Metal Strength

Which Industries Use Which Metals for Stamped Part Production?

| Industry | Preferred Materials | Why These Metals? |

|---|---|---|

| Automotive | Aluminum, Stainless | Lightweight, corrosion resistance, crash safety |

| Aerospace | Aluminum alloys | Strength-to-weight, fatigue resistance |

| Electronics | Copper, Brass | Conductivity, EMI shielding, solderability |

| Medical Devices | Stainless Steel, Brass | Hygiene, low lead content, FDA compliance |

| Plumbing & HVAC | Brass, Copper | Corrosion resistance, antimicrobial, easy forming |

| Appliances | Aluminum, Brass | Decorative surface, easy pressing, lightweight |

More examples: The Fabricator – Metal Stamping

FAQs

1. Which metal is best for precision stamping with tight tolerances?

Stainless or aluminum.

2. Can copper parts be used outdoors?

Yes, but consider protective finishes.

3. Do all these metals support engraving?

Yes. Brass and stainless offer best visibility.

4. Are there lead-free brass alloys?

Yes. C69300 and others comply with RoHS and NSF.

5. Best for marine use?

Stainless 316.

6. Stamping differences: thick vs thin?

Thick requires more tonnage; thin needs better support.

7. Aluminum for crash zones?

Yes, especially 6xxx or 7xxx series.

8. Galvanic corrosion risk?

Yes. Avoid contact between dissimilar metals without isolation.

9. Required certifications?

ISO 9001, RoHS, REACH, CE.

10. MOQ for custom parts?

Often 500–1000 pcs, varies by metal.

11. Can I get pre-anodized or polished sheets?

Yes.

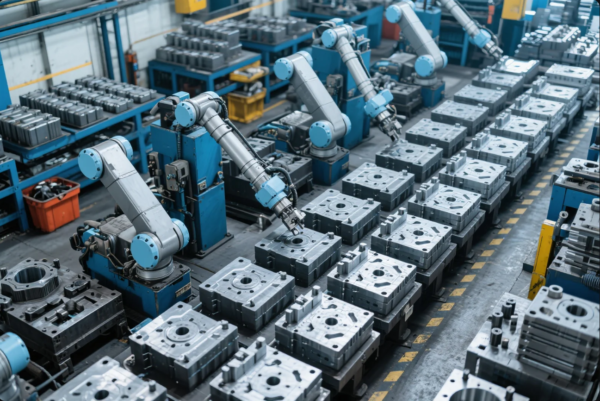

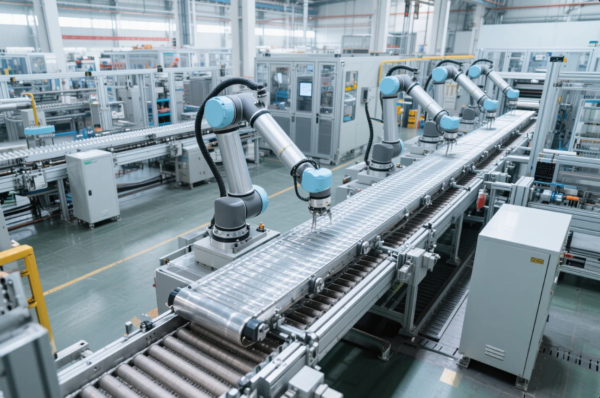

12. Is robotic stamping possible?

Yes. All metals can be processed by automated presses.

Conclusion & Contact Information

Choosing the right metal ensures high-quality stamped parts. In 2025, stainless steel, aluminum, copper, and brass all offer specific advantages. Your industry, application, and tooling define what fits best.

For precision metal stamping, visit PrimeCustomParts.com or email [email protected].

🎯 Get a free consultation, fast quote, and technical review.

📦 ISO 9001 certified, 10 production lines, flexible MOQ, fast delivery.