Welded Metal Components for Automotive, Aerospace, and Industrial Equipment

I once struggled to find welds that could withstand extreme loads. So I learned how different industries like automotive and aerospace structure their welding standards and material choices. This guide helps you build strong, reliable metal components.

Snippet paragraph:

High-stress industries demand welds with fatigue resistance, thermal stability, and precision. This guide explores industry strength requirements, material selection, OEM case studies, and benefits of integrated welding and machining workflows.

Table of Contents

- Which Industries Require the Highest Weld Strength?

- Custom Welding Materials: From Stainless Steel to Aluminum

- Case Study: Complex Welded Assemblies for OEM Applications

- Benefits of One-Stop Fabrication for Welding + Machining

- FAQs

- Contact Prime

Which Industries Require the Highest Weld Strength?

I often collaborate with engineers in aerospace, automotive, and heavy industry. Each demands welds that perform under extreme stress.

Snippet paragraph:

Aerospace welds must resist fatigue and high temperatures. Automotive welds need to survive crash and vibration. Industrial welds must last under torque and thermal cycling.

Industry Standards & Requirements

- Aerospace: Fatigue resistance, repeatable weld quality, and certifications like NADCAP. See NASA standards.

- Automotive: Requires fatigue- and crash-rated welds per SAE International. Forums often discuss steel vs. aluminum welds.

- Industrial Equipment: High-wear environments demand welds that resist mechanical stress and heat cycling. Refer to American Welding Society (AWS).

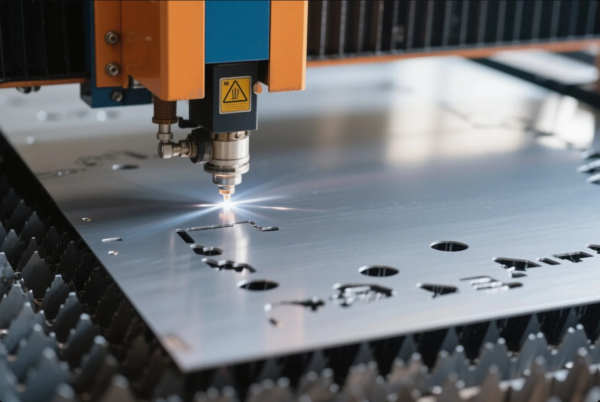

Custom Welding Materials: From Stainless Steel to Aluminum

Material choice drives weld performance. I’ve worked with a range of alloys across industries.

Snippet paragraph:

Material affects weld strength, weight, corrosion resistance, thermal behavior, and recyclability. Choosing correctly is critical for reliability and durability.

Popular Materials & Uses

| Alloy | Strengths | Common Uses |

|---|---|---|

| Stainless Steel (304, 316L) | Corrosion resistance, high strength | Food equipment, aerospace interior |

| Aluminum (6061, 7075) | Light weight, good weldability | Vehicle structures, electronics housing |

| Carbon Steel (ASTM A36) | Durable and cost-effective | Structural frames and industrial parts |

| Titanium (Ti-6Al-4V) | High strength-to-weight, biocompatible | Jet engine components and medical implants |

| Nickel Alloys (Inconel) | High-temp and oxidation resistant | Gas turbines and chemical processing |

📘 Learn about alloy properties at Total Materia link. Compare materials on Matmatch link or AZoM link.

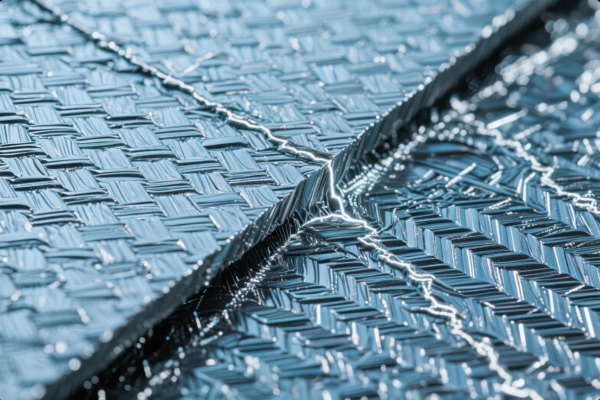

Case Study: Complex Welded Assemblies for OEM Applications

We helped an OEM develop a lightweight B-pillar assembly that passed crash tests on the first try.

Snippet paragraph:

The assembly used carbon steel, aluminum brackets, and robotic welds with careful fixture design. Quality control included ultrasonic and dye-penetrant inspections to meet Euro NCAP safety standards.

Key Project Challenges

- Weld Precision: Tight±0.5 mm tolerance for multi-axis geometry.

- Mixed Metals: MIG-welded steel and aluminum with custom filler overlap.

- Quality Control: 100% ultrasonic, radiographic testing, and visual inspection.

🔗 Learn more about mixed-metal joining on Wikipedia: Dissimilar Metal Welding.

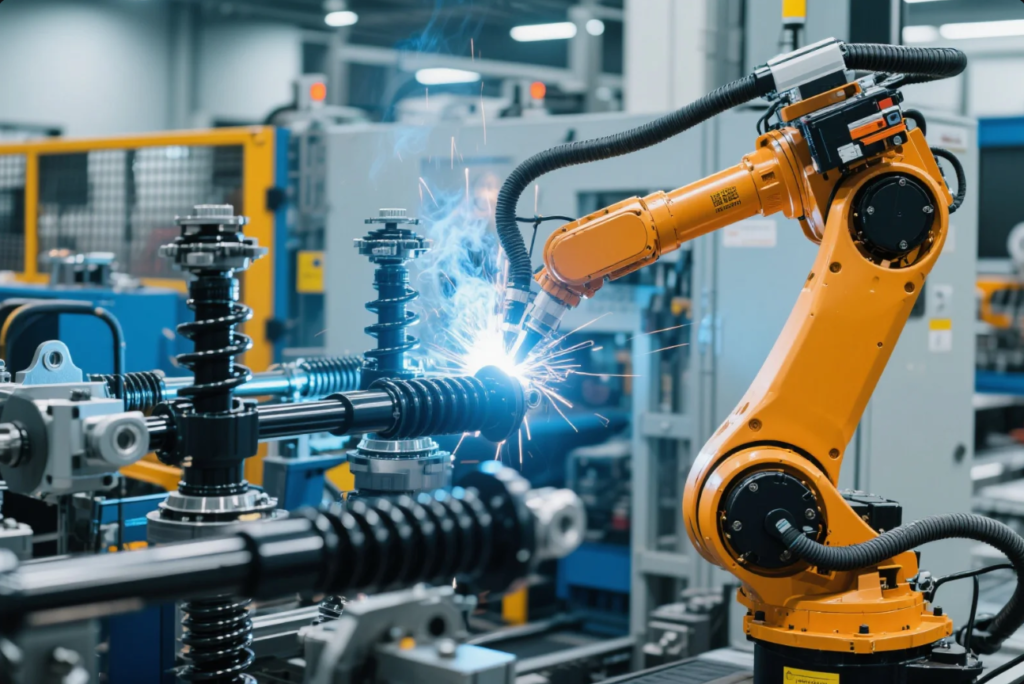

Benefits of One-Stop Fabrication for Welding + Machining

Before integrating machining, I struggled with precise tolerances post-weld. Now, everything is under one roof.

Snippet paragraph:

Integrated manufacturing improves scheduling, quality, and traceability. Machining after welding ensures fit, form, and function are precise for OEM parts.

Major Advantages

| Benefit | Description |

|---|---|

| Faster Turnaround | No need to ship parts between facilities |

| Better Tolerances | Machining fixes minor distortions from welding |

| Unified QC | Full-process traceability and single-source control |

| Cost Savings | Reduced overhead and logistics costs |

📘 Read case examples on The Fabricator link.

FAQs

Q: What is the strongest weld method for aerospace parts?

A: TIG welding with materials like titanium or Inconel meets ultra-high fatigue and heat resistance needs.

Q: Can aluminum and steel be welded together?

A: Yes—with techniques like explosive or friction stir welding; see Frisch Stir Welding.

Q: Why integrate machining after welding?

A: It ensures precise geometries and avoids fitting errors during assembly.

Q: What certifications do OEMs require?

A: ISO 9001 baseline; aerospace requires AS9100 or NADCAP; auto often requires IATF 16949.

Q: Does Prime offer automated welding?

A: Yes—our facility includes robotic MIG and TIG cells plus custom fixturing.

Q: Can Prime export globally?

A: Yes—shipping via DHL, CMA-CGM, Maersk; full import paperwork available.

📞 Contact Prime

Looking for high-performance welded metal parts with integrated machining and global delivery?

Visit us for quotes and tailored manufacturing solutions.

🌐 Website: https://primecustomparts.com

📧 Email: [email protected]

Conclusion

Building metal components for automotive, aerospace, and industry requires careful material choice, certified welding, precise fixturing, and integrated machining. Welding methods like TIG and MIG, combined with robotics and one-stop workflows, produce reliable, high-strength parts.

Choose PrimeCustomParts.com for certified, full-process manufacturing—strength, precision, and global delivery in one package.