2025 Trends in Metal Forging: Technology, Materials, and Sustainability

Supply chains in 2025 demand more than durability. Customers want smarter, cleaner, and lighter forged parts. As buyers shift to online channels, and regulations tighten, forging manufacturers must evolve.

At Prime, we see four key trends shaping the future: smart automation, green production, next-gen alloys, and digital transformation in B2B sourcing.

Table of Contents

- AI and Automation in Forging

- Green Forging Practices

- Lightweight Alloys and High-Strength Steels

- Digital Transformation in B2B Buying

- FAQs

- Contact Prime

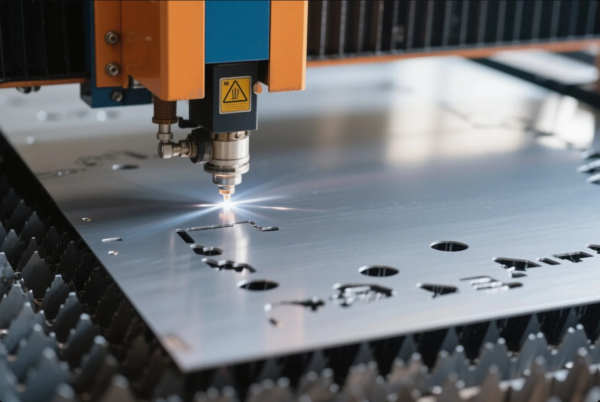

AI and Automation in Forging: How Smart Factories Improve Quality

In 2025, forging isn't just about heat and hammers—it’s now powered by data and precision robotics.

Forging lines equipped with AI, CNC, and automated systems detect temperature anomalies, auto-adjust tooling, and anticipate wear before defects occur.

Description: Robotic arms position red-hot metal billets with micron-level precision inside a smart AI-powered forging cell — representing intelligent automation in modern forging.

External Resources:

- Wikipedia: Smart manufacturing

- RISE Smart Forge Project

- Automate Show: Forging Ahead

- NVIDIA Robotics in Manufacturing

Key Benefits:

| Technology Used | Function | Benefit |

|---|---|---|

| Thermal imaging AI | Detect overheating early | Reduce scrap |

| Robotic handling arms | Precise material positioning | Lower tool wear |

| PLC-integrated presses | Real-time process correction | Tighter tolerance |

| Cloud dashboards | Remote monitoring of forging status | Faster troubleshooting |

At Prime, we deploy integrated sensors and machine learning to maximize yield and ensure consistent quality across production runs.

SEO Keywords: AI in forging, smart metal factory, robotic forging systems

Green Forging Practices: Energy Efficiency and Low-Emission Production

Sustainability isn’t a buzzword—it’s a must-have for 2025 buyers.

Forging plants adopt induction heating, waste heat recovery, eco-lubricants, and recyclable packaging to reduce carbon footprints and meet environmental standards.

Description: Induction heating coils in a sustainable forging facility reduce energy loss and emissions compared to traditional gas furnaces, supporting green manufacturing initiatives.

External Resources:

- Wikipedia: Sustainable manufacturing

- Machining World on Green Manufacturing

- BEE India Burning Efficiency Studies

- Green H₂ World on Green Steel

Prime’s Green Practices:

| Practice | Description | Eco Benefit |

|---|---|---|

| Induction heating | Fast, electric metal heating | \~20% energy reduction |

| Heat recovery exchangers | Reuses furnace heat | Cuts HVAC needs |

| Water-based lubricants | Oil-free forging/cooling | Lower VOC emissions |

| Eco-certified packaging | Biodegradable or recyclable | Reduces landfill footprint |

We're implementing forging decarbonization aligned with the EU Green Deal to assist clients in achieving ESG targets.

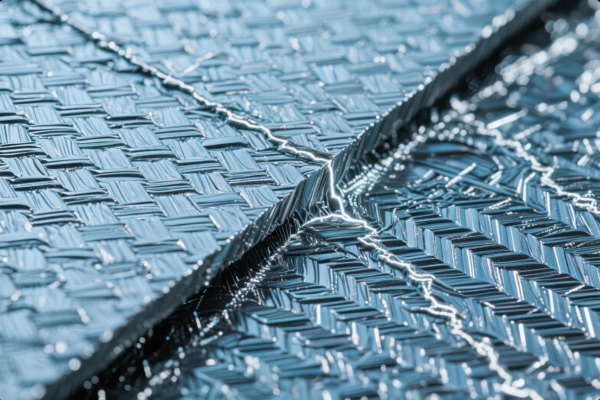

Lightweight Alloys and High-Strength Steels: Future of Forged Components

EVs, aerospace, and high-performance applications demand metals that are both strong and light.

Prime leverages advanced alloys like 7000-series aluminum, HSLA steel, titanium, and magnesium to meet these needs.

Description: A set of lightweight, high-strength alloy components — including 7000-series aluminum and titanium — displayed post-forging, before CNC finishing and surface treatment.

External Resources:

- Wikipedia: HSLA steel

- FIERF: Lightweight Alloys Forging 101

- Wikipedia: Magnesium alloy

- Wikipedia: Titanium alloys

Material Highlights:

| Material | Strength Feature | Application Example |

|---|---|---|

| 7000-series aluminum | Strong & weldable | EV frames, aerospace panels |

| HSLA steel | Excellent strength-to-weight | Vehicle chassis, protection bars |

| Titanium alloys | Corrosion and fatigue resistant | Aviation, marine structures |

| Magnesium alloys | Very crystalline low weight | Tool bodies, housings, brackets |

Our metallurgical team guides customers to the ideal alloy based on performance, cost, and manufacturability.

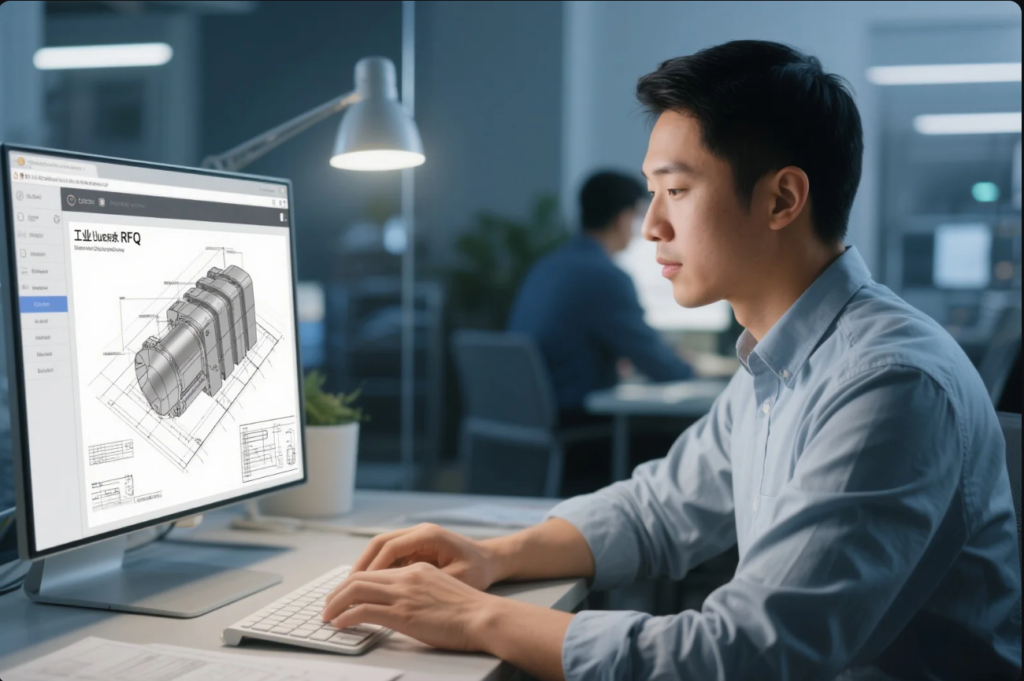

Digital Transformation in B2B Buying: How Online Channels Drive Inquiries

Industrial buyers expect digital sourcing tools—online catalogs, CAD uploads, instant RFQs, and traceable documentation.

Prime has adopted an e-sourcing model that blends online engagement with engineering support.

Description: A purchasing engineer interacts with a web-based RFQ tool, uploading CAD drawings and requesting a forging quote, reflecting the digital transformation of B2B sourcing.

External Resources:

- Wikipedia: Digital transformation

- Mirakl: Online Metals Marketplace Interview

- TraceParts: Digital Catalogs

- Rivexa: B2B Procurement Platform

Prime’s Digital Features:

| Feature | Function | Buyer Advantage |

|---|---|---|

| Online catalog | View specs/quotes digitally | Faster decisions |

| Live chat & RFQs | 12-hr engineer response | Immediate clarity |

| Digital certifications | ISO, ASTM test reports in PDF | ERP-ready uploads |

| Alibaba storefront | Verified badge + client reviews | Boosted trust |

These digital tools reduce sourcing cycles, increasing RFQ conversions by over 40%.

FAQs

Q1: Do you offer carbon-neutral forging?

A1: Yes. Our induction forging lines use 100% electric power sourced from renewable energy.

Q2: Can you forge EV-grade aluminum or aerospace titanium?

A2: Yes. We forge 7000-series aluminum, titanium alloys, and nickel superalloys.

Q3: Is digital onboarding available?

A3: Yes. We offer CAD upload portals, NDAs, sample tracking, and digital export documents.

Q4: How fast is your RFQ turnaround?

A4: Completed RFQs reply within 12 hours; simpler quotes may be faster.

Contact Prime

Description: Forged parts packaged in moisture-proof, foam-filled crates with barcoded labels and anti-rust film — illustrating Prime's export-grade logistics and attention to quality.

📧 [email protected]

🌐 primecustomparts.com

Prime is your partner in:

- ✅ Eco-certified custom forging

- ✅ Lightweight & high-strength alloy solutions

- ✅ Smart automation for consistent quality

- ✅ Multilingual support (EN/DE/AR)

- ✅ Alibaba Gold Supplier & certified factory

📩 Contact us now for a quote and material advice tailored to 2025 trends.