Springback in Sheet Metal Bending: How to Predict and Control It

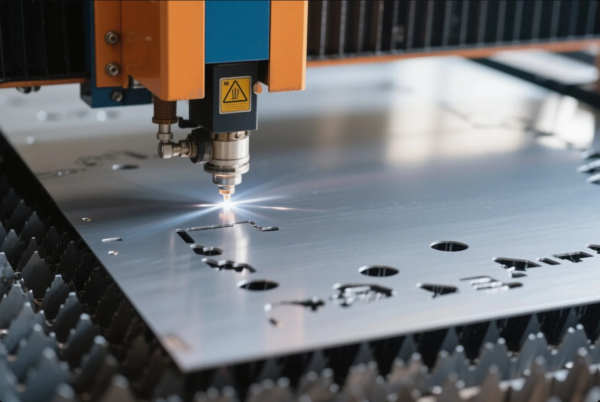

In precision sheet metal forming, one of the most common and frustrating challenges is springback—the tendency of metal to partially return to its original shape after bending. If left unaddressed, springback can result in dimensional inaccuracies, assembly issues, and costly rework.

This guide explores what causes springback, how to predict it accurately, and which methods and tools you can use to control it—ensuring each bend meets your tolerance requirements from prototyping to mass production.

📚 Table of Contents

- What Is Springback and How It Affects Final Part Geometry

- Factors That Influence Springback: Material, Radius, and Grain Direction

- Precision Bending Techniques: Bottoming, Air Bending, and Coining

- How Simulation Software Helps Compensate for Springback Before Production

- FAQs

- Contact Us

What Is Springback and How It Affects Final Part Geometry

Springback occurs when internal elastic stresses in the metal are released after forming pressure is removed. Instead of retaining the bent angle exactly, the part "springs back"—resulting in a larger internal angle than intended.

Typical consequences include:

- Misaligned holes or tabs

- Parts that won’t mate or assemble

- Cosmetic issues in visible surfaces

- Functional failures in aerospace and automotive applications

🔧 A bend intended to be 90° may open to 94° if springback is not properly accounted for.

Factors That Influence Springback: Material, Radius, and Grain Direction

Springback is not random. It is influenced by several predictable variables:

🔹 Material Type

| Material | Springback Tendency |

|---|---|

| Aluminum | High |

| Stainless Steel | High |

| Mild Steel | Moderate |

| Copper / Brass | Low |

Higher strength = higher springback. Yield strength and modulus of elasticity both affect the elastic recovery rate.

🔹 Bend Radius

Larger inside bend radii cause greater springback. Tighter bends plastically deform more of the material, leaving less residual stress.

📏 Rule of thumb: Smaller radius = less springback (but higher cracking risk in brittle materials).

🔹 Grain Direction

Bending parallel to the grain results in higher springback and a greater chance of cracking. Always design bends perpendicular to the rolling direction where possible.

Precision Bending Techniques: Bottoming, Air Bending, and Coining

Different forming methods offer different control levels over springback:

1. Air Bending

- Most common method

- Metal touches only punch tip and die edges

- Least control over springback

- Tolerances: ±0.5° to ±1.0°

2. Bottoming (Bottom Bending)

- Punch drives material into the die

- Better angle accuracy due to partial plastic deformation

- Tolerances: ±0.3° to ±0.5°

3. Coining

- High tonnage compresses material fully into the die

- Plastic deformation throughout = minimal springback

- Tolerances: ±0.1°

- Used for aerospace, electronics, or medical parts

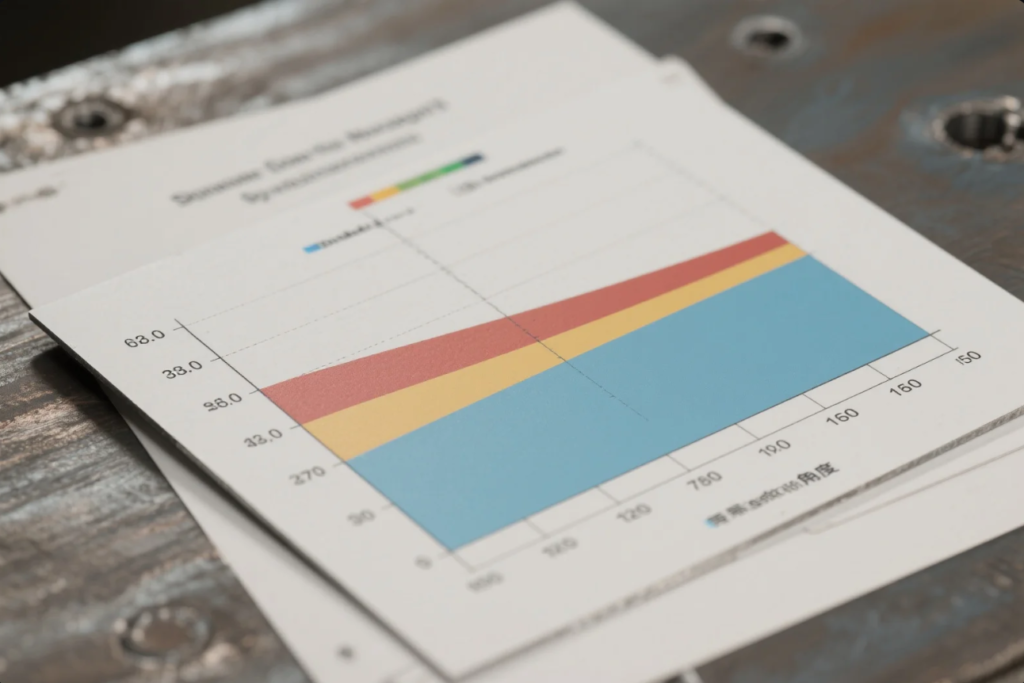

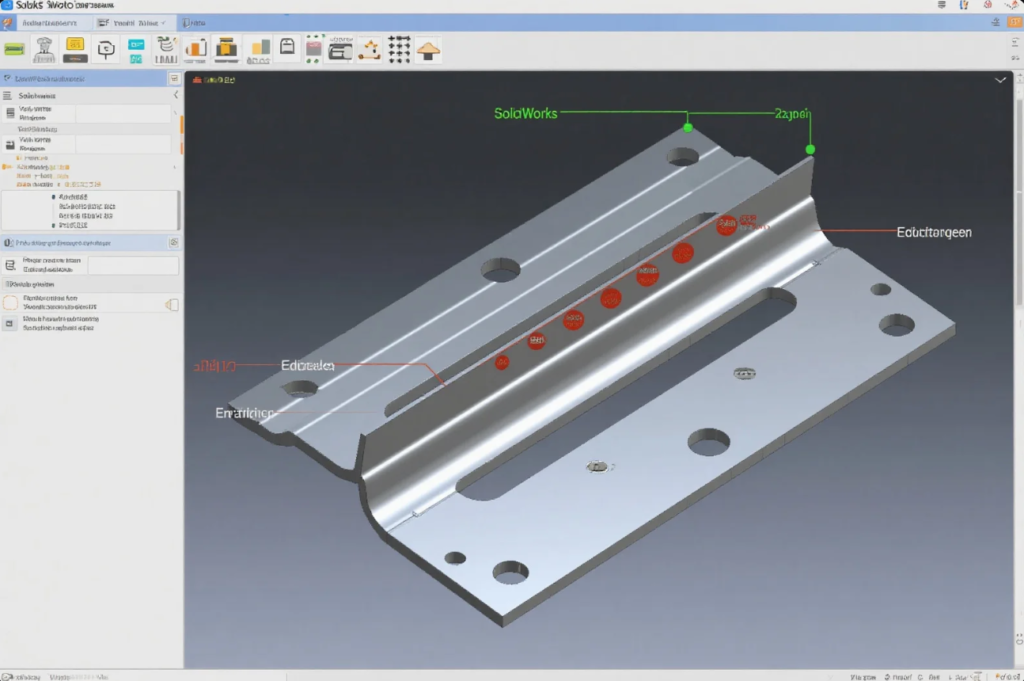

How Simulation Software Helps Compensate for Springback Before Production

Modern CAD/CAM and forming simulation software can accurately predict and correct springback before a part reaches the production line.

Leading Software for Springback Compensation:

- AutoForm – widely used in automotive

- SolidWorks Sheet Metal Add-In

- ANSYS Forming

- Logopress3 – for tool and die professionals

- Dynaform – simulation-driven tool design

Benefits:

- Generate accurate flat patterns

- Automatically adjust bend allowances

- Simulate springback angle compensation

- Minimize trial-and-error in prototyping

🔗 Learn more: AutoForm Springback Simulation

FAQs

Q1: Can springback be eliminated completely?

A: Not completely, but it can be reduced to <1° with the right forming process and simulation.

Q2: Should I always use coining to avoid springback?

A: Coining provides the highest precision but requires more tonnage and tool wear—ideal for small parts or aerospace-grade parts.

Q3: Does thicker material spring back more?

A: Not necessarily—higher strength matters more than thickness. 1.5 mm stainless steel may spring back more than 3 mm mild steel.

Q4: Can tooling be designed to “overbend” to compensate for springback?

A: Yes. Tooling is often designed with adjusted angles (e.g., 88° to achieve 90° after springback).

Contact Us

Need help controlling springback in your precision sheet metal parts?

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Prime is a global sheet metal manufacturing specialist with over 20 years of experience, ISO-certified quality, and full support for simulation-driven forming, DFM consulting, and tight-tolerance production.