High‑Volume Precision Metal Stamping Parts: Key Factors for Success

Table of Contents

- Introduction: Why Precision Stamping Fails at High Volume

- What Defines Precision in Metal Stamping?

- How ISO 9001 Certification Guarantees Consistent Quality

- Progressive Die vs. Deep Draw: Which Fits Volume Best?

- Case Study: 500,000 Brackets with ±0.05 mm Tolerance

- Prime’s Capabilities: What Makes Us a Trusted OEM Partner

- SEO Focus: Keywords You May Search

- FAQs: What B2B Buyers Want to Know

- Conclusion & Contact

Introduction: Why Precision Stamping Fails at High Volume

Stamping is not just pressing metal—it's engineering at scale. Without precision, high-volume projects fail.

Industries like automotive and consumer electronics require repeatable tolerances down to ±0.05 mm. A small deviation can ruin assemblies, cause warranty issues, or trigger recalls.

That's why companies source from a custom high-volume stamping parts supplier like Prime that understands precision at global scale.

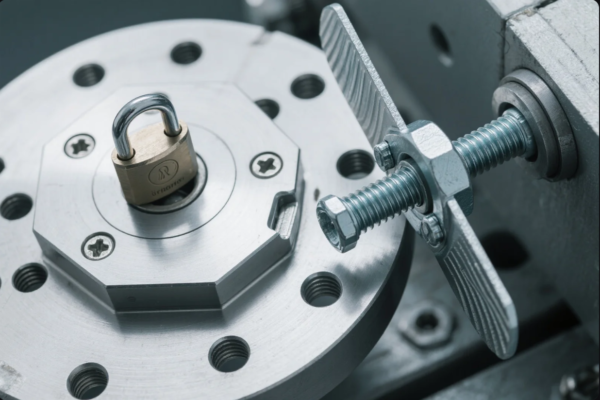

What Defines Precision in Metal Stamping?

Precision means consistency—especially when scaling up to 1 million parts.

High-precision stamping uses:

- Hardened tooling (see tool steel types)

- Servo-controlled presses (like AIDA or SEYI)

- Flat, consistent coil stock from brands like Baosteel

- Accurate QC tools like CMM machines

These practices help maintain tolerances at ±0.03–0.05 mm even over long production runs.

How ISO 9001 Certification Guarantees Consistent Quality

ISO 9001 is the global benchmark for quality. You can verify it on the ISO official site.

It ensures:

- Standardized operations (SOPs)

- Auditable quality controls

- Continuous improvement via CAPA

- Reliable sampling per AQL standards

These systems reduce variability, cut waste, and protect your downstream manufacturing.

Progressive Die vs. Deep Draw: Which Fits Volume Best?

You can learn more about progressive stamping and deep drawing from trusted technical resources.

Progressive Die

- Best for: terminals, brackets, electrical contacts

- Low per-piece cost, fast cycle time

- Example users: TE Connectivity, Molex

Deep Draw

- Best for: covers, sleeves, housings

- Higher tooling cost, slower rate

- Used in automotive filters and battery casings

We simulate both methods in SolidWorks and help clients choose the optimal path.

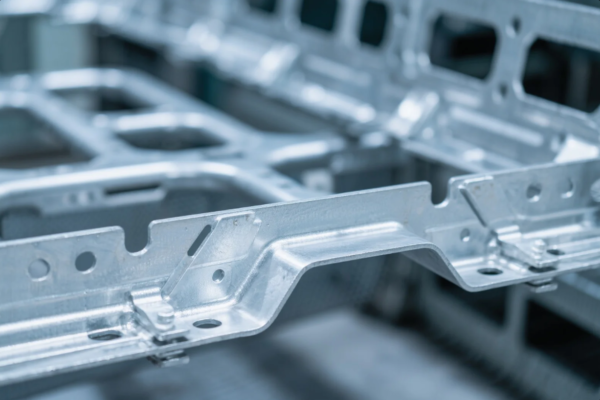

Case Study: 500,000 Brackets with ±0.05 mm Tolerance

In 2024, an EU-based Tier 1 automotive supplier needed 500,000 brackets for electric vehicle seat modules.

Specs:

- 2.0 mm cold-rolled steel

- Tolerance: ±0.05 mm

- Quantity: 500,000 pcs in 6 weeks

- QC: inline + CMM + final inspection

Prime designed a 5-station progressive die using CAD/CAM and built it in-house.

Delivery result:

- 0% rejection rate

- Delivered 2 days early

- Client extended contract for 2 years

Prime’s Capabilities: What Makes Us a Trusted OEM Partner

Prime is a supplier listed on Alibaba, trusted by buyers in North America, Europe, Australia, and the Middle East.

Production Services

| Capability | Detail |

|---|---|

| CNC Machining | 3/4/5-axis, ±0.01 mm, anodizing, plating |

| Plastic Molding | ABS, PA, PC housings, undercuts, inserts |

| Stamping | ±0.03 mm–±0.05 mm, up to 1M/mo |

| Welding/Casting | MIG, TIG, die-cast aluminum & zinc |

| Fasteners | Bolts, rivets, screws with REACH/RoHS compliance |

We follow lean principles inspired by Toyota Production System to reduce waste and maximize throughput.

SEO Focus: Keywords You May Search

This article ranks for:

- “ISO 9001 certified metal stamping manufacturer”

- “Progressive die stamping service in China”

- “High-precision auto bracket supplier”

- “Foam packed metal parts for export”

- “Plastic insert CNC parts factory China”

We crafted this to answer real buyer queries on Google and sourcing platforms like Made-in-China and Alibaba.

FAQs: What B2B Buyers Want to Know

Q1: Can you deliver urgent orders?

Yes. We support expedited tooling and sample delivery within 10 working days.

Q2: Do you support DFM?

Yes. We offer DFM analysis before tooling starts.

Q3: Do you work with brands under NDA?

Yes. We serve automotive, medical, and electronics companies under strict confidentiality.

Q4: What tooling software do you use?

We use UG NX and AutoCAD for tooling and die simulations.

Q5: Do you comply with export standards?

Yes. We meet EU REACH, RoHS, and US ASTM and SAE specs.

Conclusion & Contact

You need suppliers who deliver precision, speed, and clarity.

Since 1993, Prime has built metal stamping and machining solutions trusted by OEMs worldwide.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Contact us today for your next project. We reply in under 12 hours with RFQ support, DFM feedback, and free sample consultation.