How to Meet Tight Tolerances in Precision Metal Stampings

Table of Contents

- Tolerance Levels: ±0.05 mm vs. ±0.01 mm

- Key Influencing Factors for Achieving Tight Tolerance

- Tooling Design and Die Maintenance Strategies

- In-Process Inspection and First-Article Testing

- Case Study: Maintaining ±0.025 mm in Surgical Components

- Prime’s Engineering Support & Quality Framework

- Best Practices for Buyers

- FAQs for Buyers

- Conclusion & Contact Information

Tolerance Levels: ±0.05 mm vs. ±0.01 mm

60% of metal stamping buyers consider tolerance the single most important spec. Let’s define levels:

- ±0.05 mm fits general applications like enclosures or brackets.

- ±0.01 mm suits surgical, aerospace, or microelectronic components.

Achieving these ranges demands control across every manufacturing step.

References:

Key Influencing Factors for Achieving Tight Tolerance

Materials and Environment

- Flat, clean coils from Baosteel, Thyssenkrupp

- Consistent temperature (20±1°C) and humidity in factory

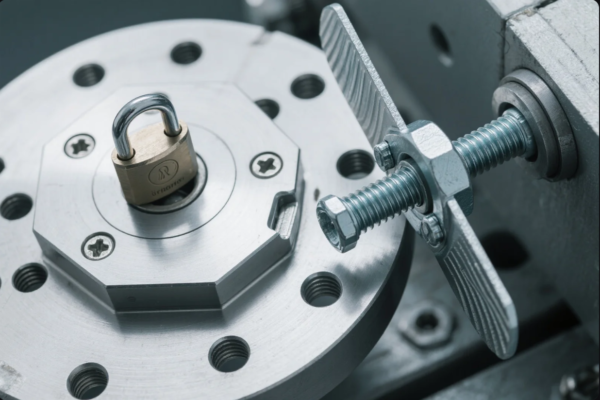

Tooling Design

- CAD simulations using SolidWorks, UG NX

- Replaceable inserts, hardened guides, minimal play

Press Equipment

- Closed-loop servo presses

- Real-time tonnage sensors, thermal controls

Inspection Integration

- Keyence vision systems for live inspection

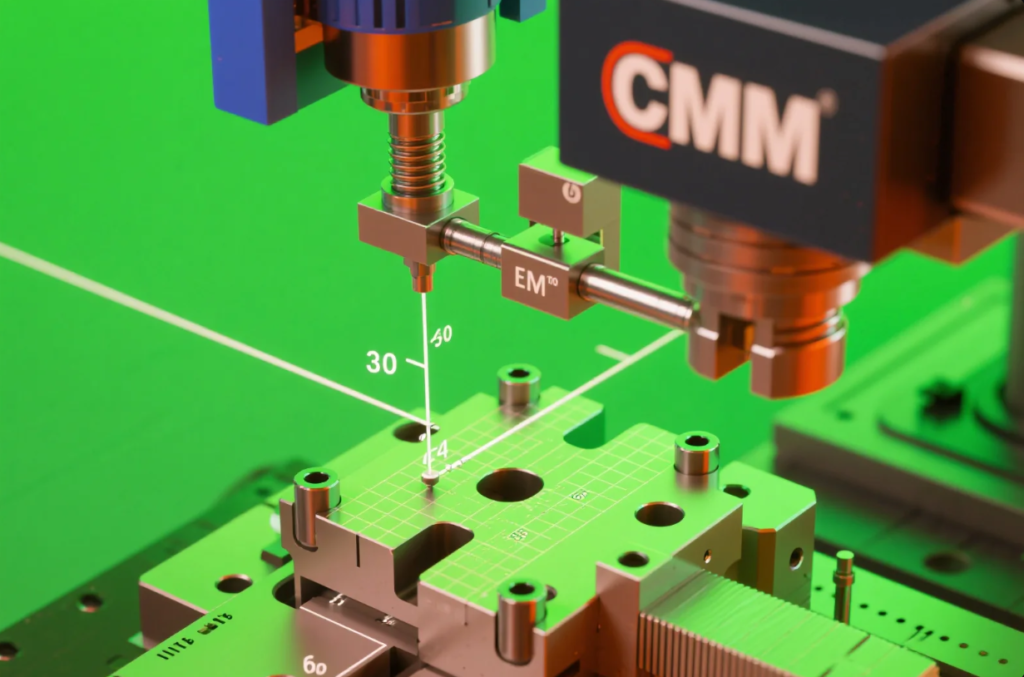

- CMM equipment for dimensional reports

Tooling Design and Die Maintenance Strategies

Design Principles

- Feature positioning based on FEM

- Die clearance tuned for specific materials

- Alignment via shoulder bushings

Maintenance Strategy

- Daily: clean, re-lube

- Weekly: visual wear review

- Monthly: insert checks

- Quarterly: surface regrind and hardness tests

In-Process Inspection and First-Article Testing

Continuous Monitoring

- Sensor tracking of press force

- SPC software logging measurements

- Triggered shutdown on tolerance drift

First Article Inspection (FAI)

- CMM checks first 10 pieces

- FAI per PPAP guidelines

- CMM overlay and SPC graphs generated

Case Study: Maintaining ±0.025 mm in Surgical Components

Background

Client needed 10,000 surgical clips with ±0.025 mm flatness and no burrs.

Execution

- Material: 316L stainless

- Die: Progressive, with thermal control

- Equipment: Servo press with feedback loop

- Inspection: CMM and vision every 500 pcs

- Packaging: Sealed Air moisture-controlled

Results

- ±0.025 mm achieved in 100% parts

- 99.95% yield

- Project expanded to 3 other components

Prime’s Engineering Support & Quality Framework

Certifications & Process

- ISO 9001

- Traceable batch IDs

- Operator-level SOPs

- CAPA logs for any deviation

Digital Traceability

- Die #, coil ID, shift ID on each label

- Linked to part inspection and packaging data

Best Practices for Buyers

- Submit CAD files (STEP, IGES)

- Define tolerance zones clearly

- Specify test frequency

- Confirm FAI and PPAP requirements

- Request maintenance and inspection templates

- Ask for CPK and run charts for ongoing production

Additional guidance:

FAQs for Buyers

Q: Can you reach ±0.01 mm in copper?

A: Yes, with hardened tools and 0.5 mm+ thickness.

Q: Do you inspect 100%?

A: Vision systems check every 10 pieces; SPC triggers full inspection when needed.

Q: Are reports customizable?

A: Yes. PDF, Excel, barcode format available.

Q: Do you offer plated finishes?

A: Yes, including bright nickel, tin, black oxide, passivation.

Q: What’s your tooling lifetime?

A: 500K–1M+ strokes depending on material and die care.

Conclusion & Contact Information

To meet ±0.01 mm tolerances, every detail matters—from die design to environmental control to inspection strategy. Prime delivers tight-tolerance parts for aerospace, electronics, and med-tech—on time, every time.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Reach out for a free DFM review, quotation, or sample consultation.