Top 5 Applications of Metal Stamping Parts Across Industries

Table of Contents

- Automotive Applications

- Electronics Applications

- Aerospace Applications

- Consumer Appliances Applications

- Industrial & Other Applications

- Prime’s Expertise & Quality Assurance

- FAQs

- Conclusion & Contact Information

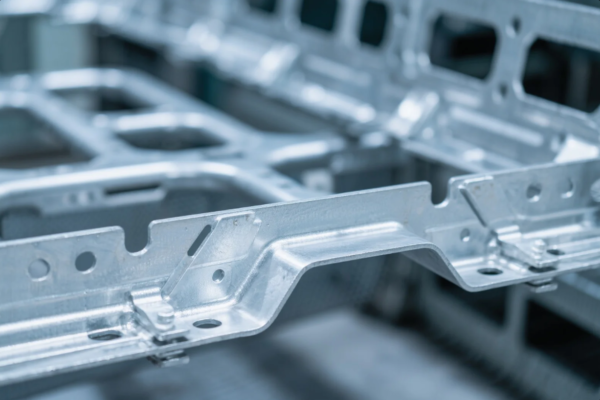

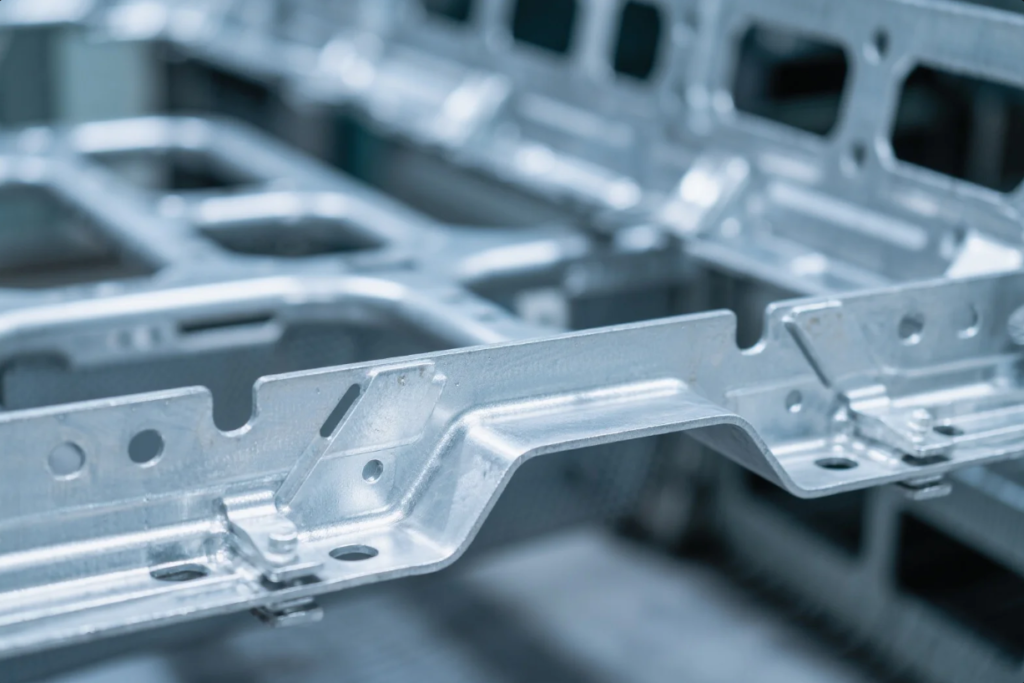

Automotive Applications

Metal stamping plays a critical role in the automotive industry. Components like brackets, chassis parts, and fuel tank elements rely heavily on precision stamping methods.

Brackets & Supports

These components mount engines, transmissions, seats, and more. They must comply with IATF 16949 standards for quality. Learn more about automotive quality standards from IATF Global Oversight.

Chassis & Reinforcements

Chassis parts are often made from high-strength low-alloy steel (HSLA), providing strength and crash safety. Components like crossmembers are deep-drawn or progressive-stamped.

Fuel Tank Components

Fuel tank straps, ends, and mounting plates made from aluminized steel resist corrosion. These comply with “SAE J2260", a standard for fuel tank safety.

Electronics Applications

Electronic devices rely on stamped metal parts for connectivity, thermal management, and electromagnetic compatibility.

Connectors & Contacts

Brass, phosphor bronze, and beryllium copper are stamped into terminals and pins. Check material specs at TE Connectivity.

Heat Sinks & Fins

Stamped fins made of aluminum or copper are common in LEDs, power supplies, and computing devices. Learn about heat sink production from Cooler Master and Wikipedia – Heat sink.

EMI/RFI Shielding

Nickel-plated steel shields protect sensitive electronics from interference. See more at IEEE on EMI shielding.

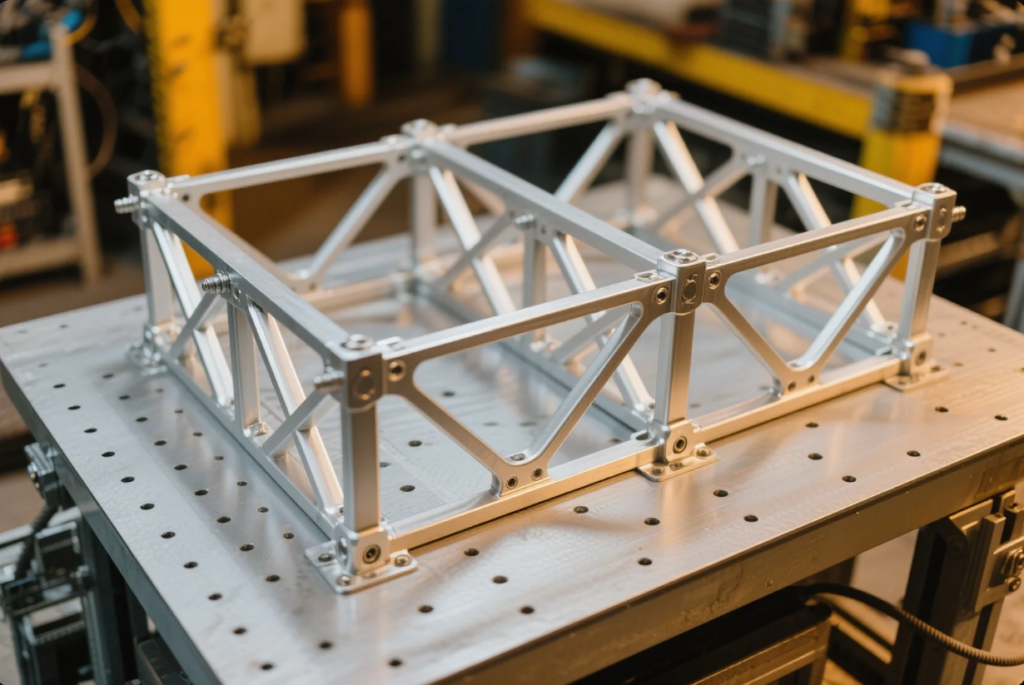

Aerospace Applications

Aerospace parts require high strength, low weight, and stringent certification. Metal stamping is vital to meet these criteria.

Structural Ribs & Gussets

Made from 2024 or 7075 aluminum and sometimes even titanium, these parts support aircraft structures. Read on Aerospace Materials.

Mounting Brackets & Fasteners

FAA-spec brackets require precise forming and corrosion resistance. Learn about aerospace fasteners from NASASpaceflight.

Fuel & Hydraulic Components

Stamped tanks, filter housings, and valve components must be leak-proof and durable. Explore standards at Aerospace Industries Association.

Consumer Appliances Applications

High-volume consumer goods rely on efficient stamping for panels, frames, and hardware.

Appliance Panels & Doors

Refrigerator, oven, microwave parts are stamped at high volumes from cold-rolled steel. See Electrolux appliances.

Fastener Clips & Spring Parts

Used in washing machines, HVAC systems, and more, these small parts are often stamped and heat-treated. The Appliance Standards Awareness Project has details on compliance.

Motor and Fan Components

Motor housings and lamination stacks are manufactured using progressive stamping. Read about industrial fan design at Zoro.com.

Industrial & Other Applications

Stamping is also essential across diverse sectors such as HVAC, power, healthcare, and lighting.

- HVAC: Stamped vents, coils, and frames per ASHRAE standards

- Power Systems: Transformer laminations and electrical enclosures

- Medical Devices: Shims, mini clips, sensors—manufactured per FDA guidelines

- Lighting: Reflectors, heat shields, and panel frames

- Construction: Hardware like brackets, hinges, and fasteners

Explore HVAC component standards at ASHRAE and transformer specs at ABB.

Prime’s Expertise & Quality Assurance

Deep-Drawing & Progressive Stamping

Prime supports both techniques with capacity for both thick and thin gauges using servo-presses.

Tight-Tolerance Achievement

Standard tolerances: ±0.02 mm for brackets, ±0.01 mm for medical/electronics. See tolerance guides at ISO 2768.

Certifications Across Industries

- ISO 9001 (quality management)

- IATF 16949 (automotive supply)

- FAA traceability and documentation for aerospace

- FDA and ISO 13485 for medical devices

Material Versatility

We work with stainless, HSLA, copper, aluminum, titanium, nickel alloys, and exotic metals from suppliers like Alcoa and Albany Metals.

Finishing & Inspection

Options include plating, powder coating, anodizing, passivation, heat treatment. Quality verified using CMM, vision systems, and FAI per PPAP.

FAQs

Q: What is your max capacity per month?

A: Up to 5 million parts/month across high-speed presses.

Q: What thickness can you stamp?

A: Up to 4 mm steel, 3 mm aluminum, 2 mm copper.

Q: Can you handle certifications?

A: Yes — including ISO, IATF, FAA documentation, and FDA/ISO 13485.

Q: Do you offer custom packaging?

A: Yes — foam-in-place, vacuum, barcoded labels, per tough shipping standards.

Conclusion & Contact Information

Metal stamping is essential across automotive, electronics, aerospace, appliances, and more. With volume, quality, and industry compliance, stamping remains cost-effective and reliable.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Contact us today for sample quotes, design review, or 24-hour RFQ turnaround. Let Prime help you succeed in stamping innovations.