Custom Metal Fasteners for High‑Load Industrial Applications

Struggling to find the right fasteners for heavy-duty machines?

High-load industries like aerospace and automotive require custom fasteners built to withstand extreme stress, vibration, and precision demands. Learn what matters most.

Fastener failure isn't an option when safety and load-bearing are involved. Let’s explore how to design reliable industrial fasteners.

🧭 Table of Contents

- Introduction

- Designing Fasteners for Automotive & Aerospace Use

- Precision Requirements: Thread Fit & Tolerance

- Custom Shapes: Studs, Clips, Self-Clinching Inserts

- Quality Control & ISO 9001 Certification Insights

- FAQs

- Conclusion & Contact

Introduction

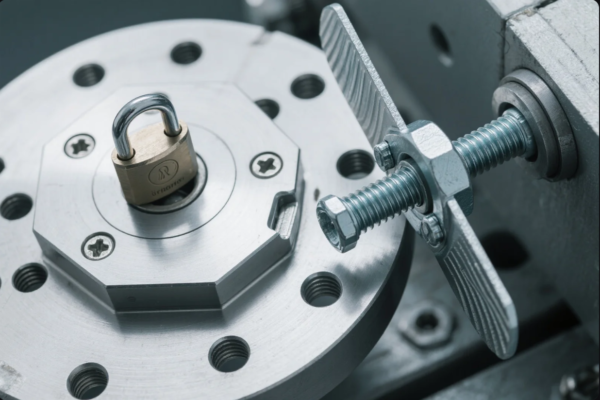

High-load environments don’t tolerate compromise. From turbine housings to vehicle subframes, every connection must hold under pressure. At Prime, we’ve supported industrial clients with customized high-torque fasteners, crafted for the extreme loads of automotive and aerospace sectors.

This guide will walk you through essential fastener design elements—thread tolerances, custom forms, material treatment, and certified quality. Whether you need bolts for aircraft assembly or locking inserts for engines, this is your blueprint for performance-grade fasteners.

Resources:

Designing Fasteners for Automotive & Aerospace Use

Automotive and aerospace fasteners endure stress, heat, and vibration. Their design must account for more than just tensile load.

Custom fasteners for high-load use need specific materials, coatings, and thread patterns. Design begins with the application environment.

| Application | Design Consideration | Fastener Example |

|---|---|---|

| Automotive Engine | Heat resistance, fatigue load | Grade 10.9 hex bolts with phosphate coat |

| Aerospace Wing | Vibration resistance, lightweighting | Titanium bolts with 6-lobe heads |

| Chassis Frames | Impact load, shear strength | Flanged bolts, lock nuts, washers |

Case: A Tier 1 German automotive firm needed engine bolts for 500+ Nm torque. Prime delivered custom carbon-molybdenum alloy M14 bolts, phosphate-coated and heat-treated.

More specs:

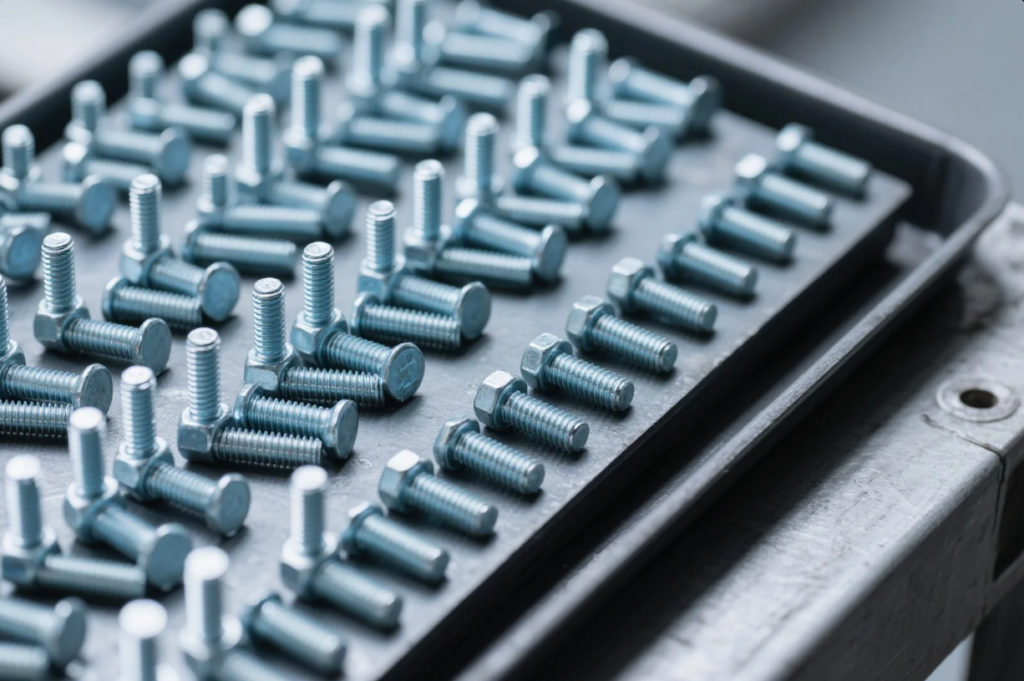

Precision Requirements: Thread Fit & Tolerance

Threaded fasteners in high-load systems must meet tight tolerances. Poor fit causes vibration, fatigue, and failure.

Precision threads ensure proper torque transmission and resistance to loosening under load.

| Thread Class | Clearance Type | Use Case |

|---|---|---|

| ISO 6g/6H | Standard fit | General chassis bolts |

| ISO 4H/5g6g | Tight fit | Aerospace and rotating assemblies |

| ANSI 2A/2B | Loose fit | Construction fasteners |

| ANSI 3A/3B | Close fit | Engines, hydraulic systems |

Prime’s fastener lines include CNC-rolled threads and 100% in-process gauging. Optical comparators verify pitch and flank angle within ±6 μm.

Real example: A U.S. drone client required M10 bolts with <6μm pitch deviation. Prime produced them using Swiss lathes and full traceable inspection logs.

Technical links:

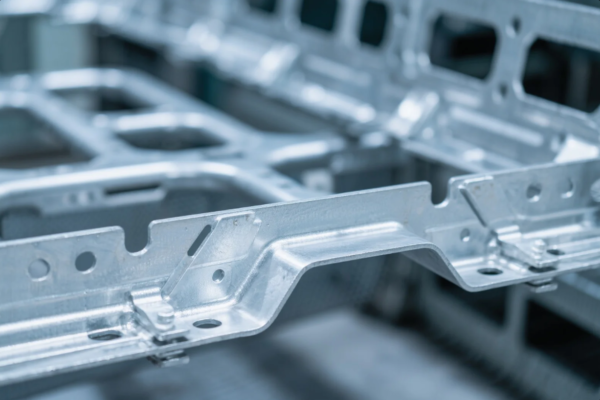

Custom Shapes: Studs, Clips, Self‑Clinching Inserts

Standard bolts can’t always meet your geometry needs.

Custom shapes like studs, clips, and clinch inserts offer high function in compact spaces or for specialty surfaces.

| Shape Type | Use Case | Industry |

|---|---|---|

| Threaded Studs | Permanent alignment points | Automotive engines, electric motors |

| U/J Clips | Blind-side mounting | HVAC, dashboard, electronics |

| Clinching Inserts | Threads in thin sheet materials | Aerospace, telecoms, medical devices |

Advantages:

- Studs reduce alignment error.

- Clips simplify back-side inaccessible fastening.

- Clinching inserts allow threads in panels as thin as 0.5 mm.

Case: A battery maker needed M3 clinching nuts for aluminum housings. Prime delivered parts with press-in installation and 1,500+ vibration cycle durability.

Resources:

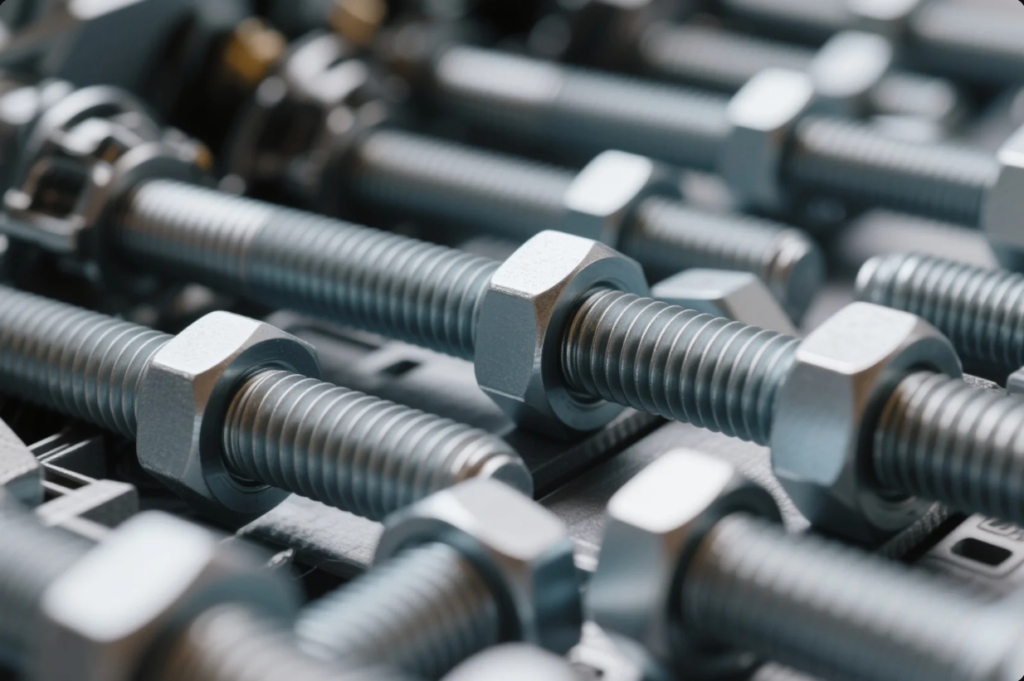

Quality Control & ISO 9001 Certification Insights

High-load components require rigorous inspection and certification.

Certified fastener manufacturing builds confidence through test documentation, traceability, and international compliance.

| QC Step | Description | At Prime |

|---|---|---|

| Incoming Raw Check | Verify alloy chemistry & strength | Lab spectrometer + tensile test |

| In-process QC | Dimension + surface roughness | Auto CNC probe + visual scan |

| Final Functional Testing | Vibration, shear, pull-out simulation | Torque bench & test rig |

| Documentation | Full batch, operator, material reports | Digital reports + barcode scan |

Our ISO 9001:2015-certified systems include CoC, plating test, and hardness reports with every batch. Rejection rate: under 0.8% annually.

Case: A rail construction project in UAE demanded DIN bolts with 80-hour salt-spray performance. Prime passed their QA in 24 hours due to complete ISO docs.

Relevant links:

FAQs

1. What’s the benefit of custom fasteners over standard ones?

Custom fasteners offer fit, finish, and performance tailored to your exact assembly.

2. What tolerances should I specify for aerospace bolts?

Use ISO 4H/5g6g or ANSI 3A/3B with documentation of gauge compliance.

3. Can I request salt spray test reports with my order?

Yes. Prime includes salt spray (ASTM B117), adhesion, and RoHS/REACH docs upon request.

4. How are thread tolerances verified?

Via CNC probing, Go/No-Go gauges, and optical pitch measurement.

5. How fast can custom orders be delivered?

Prototype lead time: 7–15 days. Mass production: 20–30 days, with priority air freight available.

Conclusion & Contact

Custom fasteners are critical for high-load industries. At Prime, we provide ISO-certified threaded parts engineered for your load, fit, and environment—whether for aerospace turbines, electric vehicle housings, or machinery.

📩 Contact us for:

- CNC-grade custom bolts, nuts, studs, clips

- Coating & plating consultations

- Full ISO & test documentation

- Short lead times and global export

🌐 Website: https://primecustomparts.com

✉️ Email: [email protected]

Let’s engineer performance—one fastener at a time.